Facility fishery feeding system

A fishery and facility technology, applied in the field of facility fishery feeding system, can solve the problems of failing to promote efficient transfer of fishery materials and products, increasing construction intensity and difficulty, and low degree of automation, so as to avoid uneven feeding of feed and reduce labor Intensity, even feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be described in detail below with reference to the drawings and embodiments, but the present invention is not limited to the scope of the embodiments.

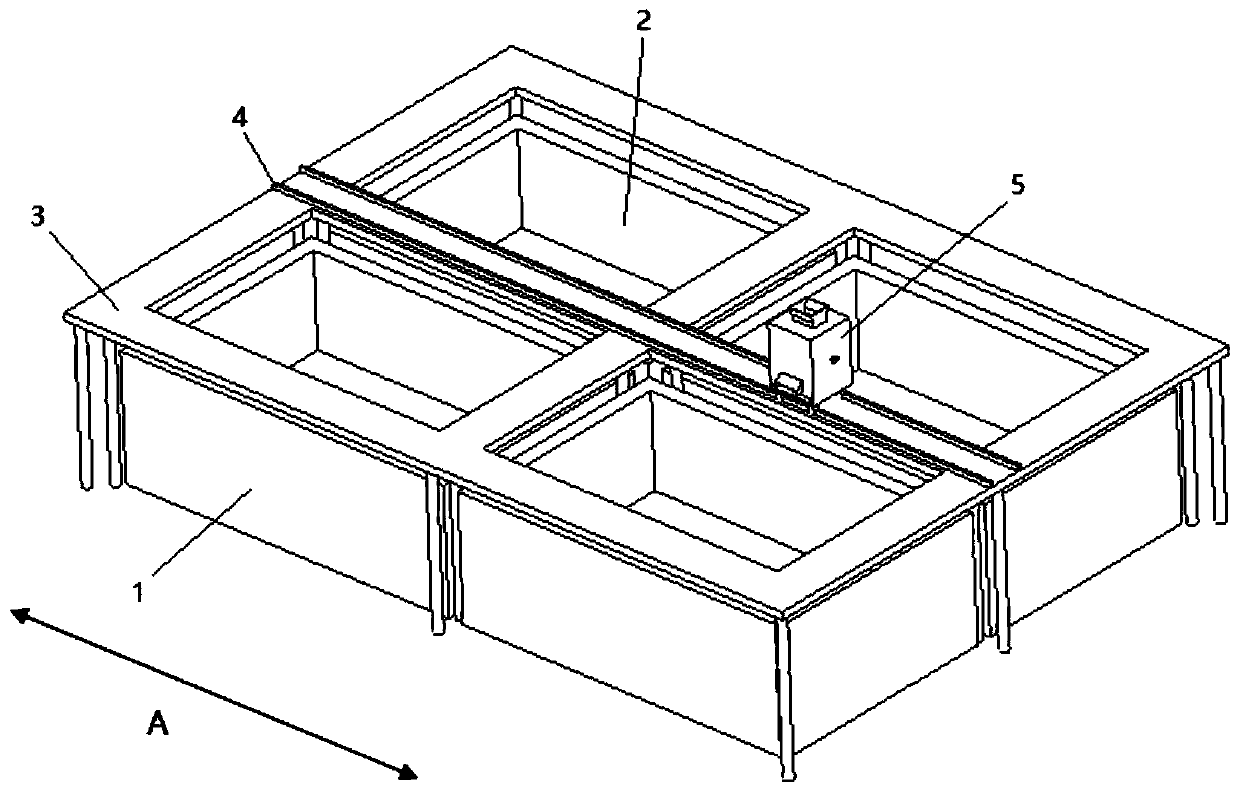

[0047] Such as Figure 1 to Figure 4 As shown, the feeding system for facility fishery 1 according to the present invention includes a culture pond 1; a feeding area 2 is provided in the culture pond 1;

[0048] The support 3 is arranged around the feeding area 2 and is located above the cultivation pond 1;

[0049] The feeding rail 4 is arranged on the support 3 and extends along the first direction A;

[0050] The feeder 5 is arranged on the feed rail 4 and moves along the first direction A;

[0051] When multiple groups of breeding ponds are arranged in parallel, the feeding track 4 is arranged on the support 3 and extends along the vertical direction of the first direction A;

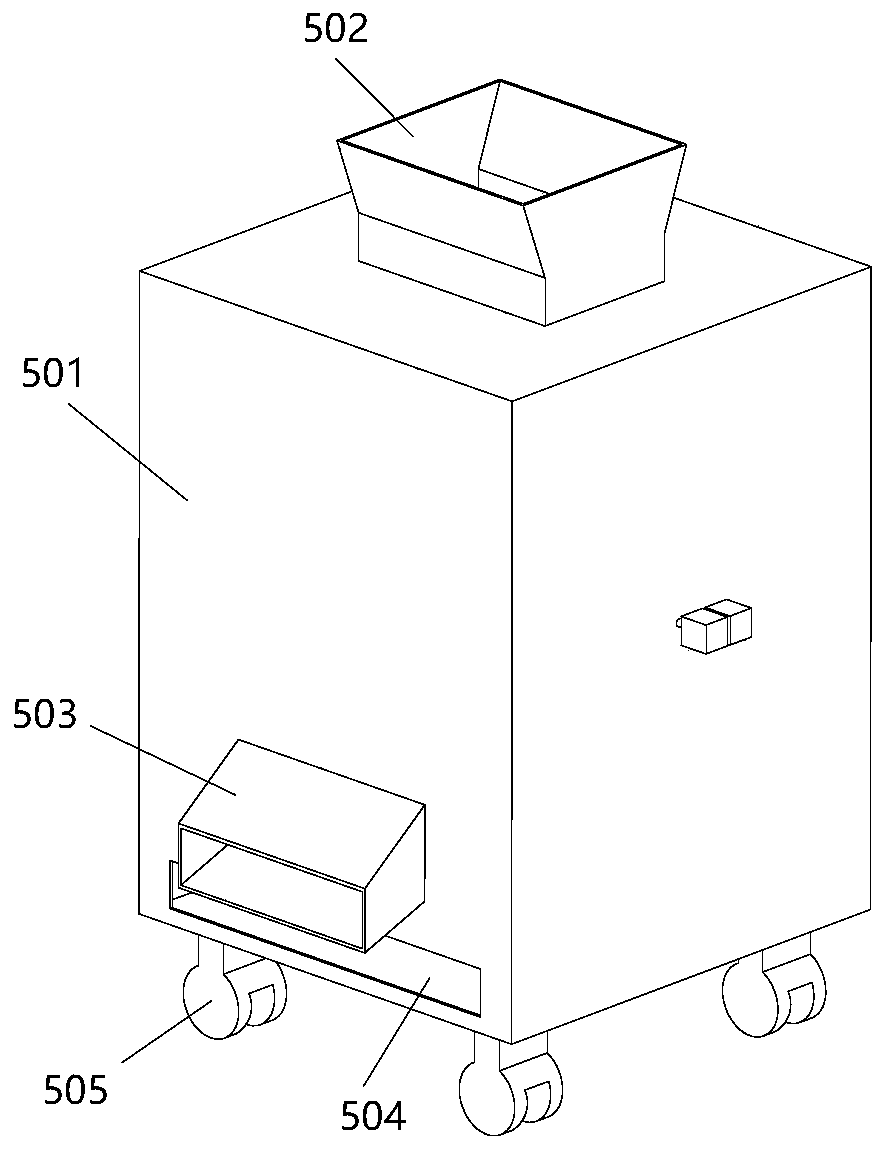

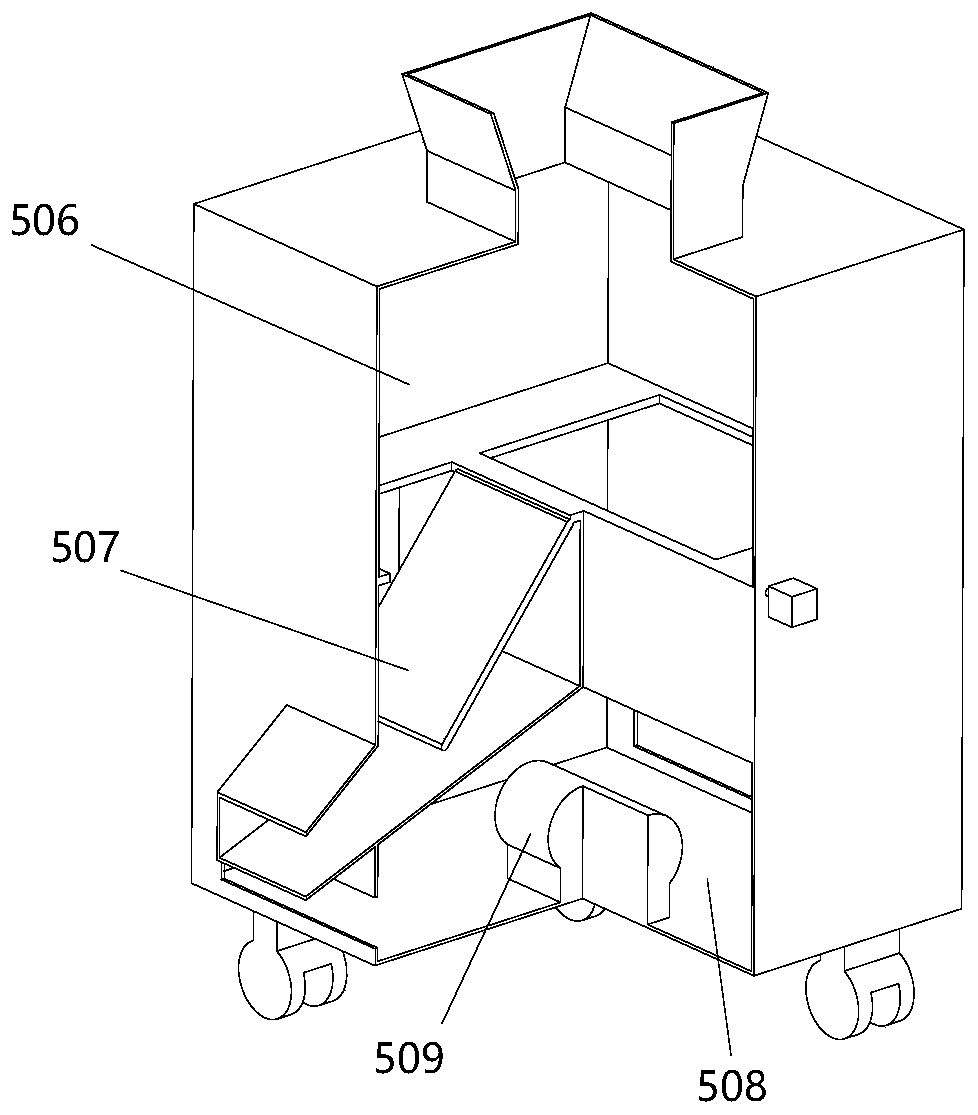

[0052] The feeder 5 includes a storage box 501 for storing the fed feed; a feed opening 502 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com