Drilling device for aircraft panel skin

A technology for aircraft wall panels and hole-making devices, which is applied to aircraft parts, manufacturing tools, transportation and packaging, etc., can solve the problems of high investment cost of special equipment, small number of guide bush holes, and low drilling efficiency, and reduce the development cost. Lower cost, improved hole making accuracy, wide range of available effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in this embodiment, the orientation words "upper, lower" and other orientation words are described according to the drawings, and do not constitute a limitation to the present invention.

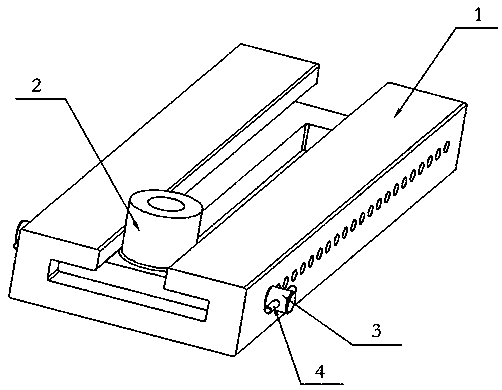

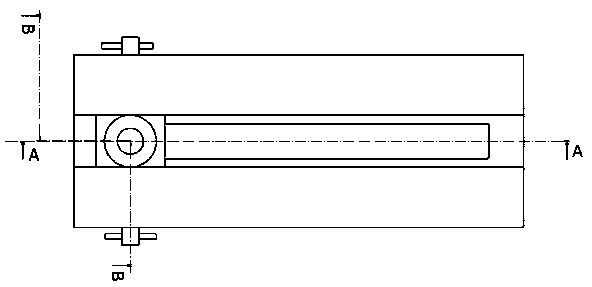

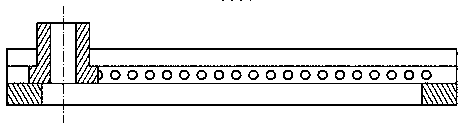

[0028] Attached below Figure 1-8 The present invention is described further: a kind of precise hole-making device of aircraft panel, as Figure 1-4 As shown, it includes guide rail base 1, drill bushing 2, positioning pin 3 and handle 4, guide rail base 1 is fixed on the skin of aircraft panel, drill sleeve 2 is installed on guide rail base 1, and can be mounted on guide rail base 1 Sliding, the positioning pin 3 is used to fix the drill sleeve 2 on the guide rail base 1, and the handle 4 is installed on the end of the positioning pin 3 .

[0029] Such as Figure 5 As shown, the guide rail 1-1, the hole making groove 1-2, the positioning pin hole 1-3 and the bottom surface of the guide rail base 1-4 are set on the guide rail base 1; the guide rail 1-1 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com