Bi-component hyperbranched polyester resin high-solid-content high-gloss varnish for urban rail and bullet train bodies and preparation method thereof

A technology of hyperbranched polyester and high solid content, applied in the field of coatings, can solve the problems of high VOC in construction and difficult to achieve, and achieve the effects of improving various properties, good storage stability and shortening preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

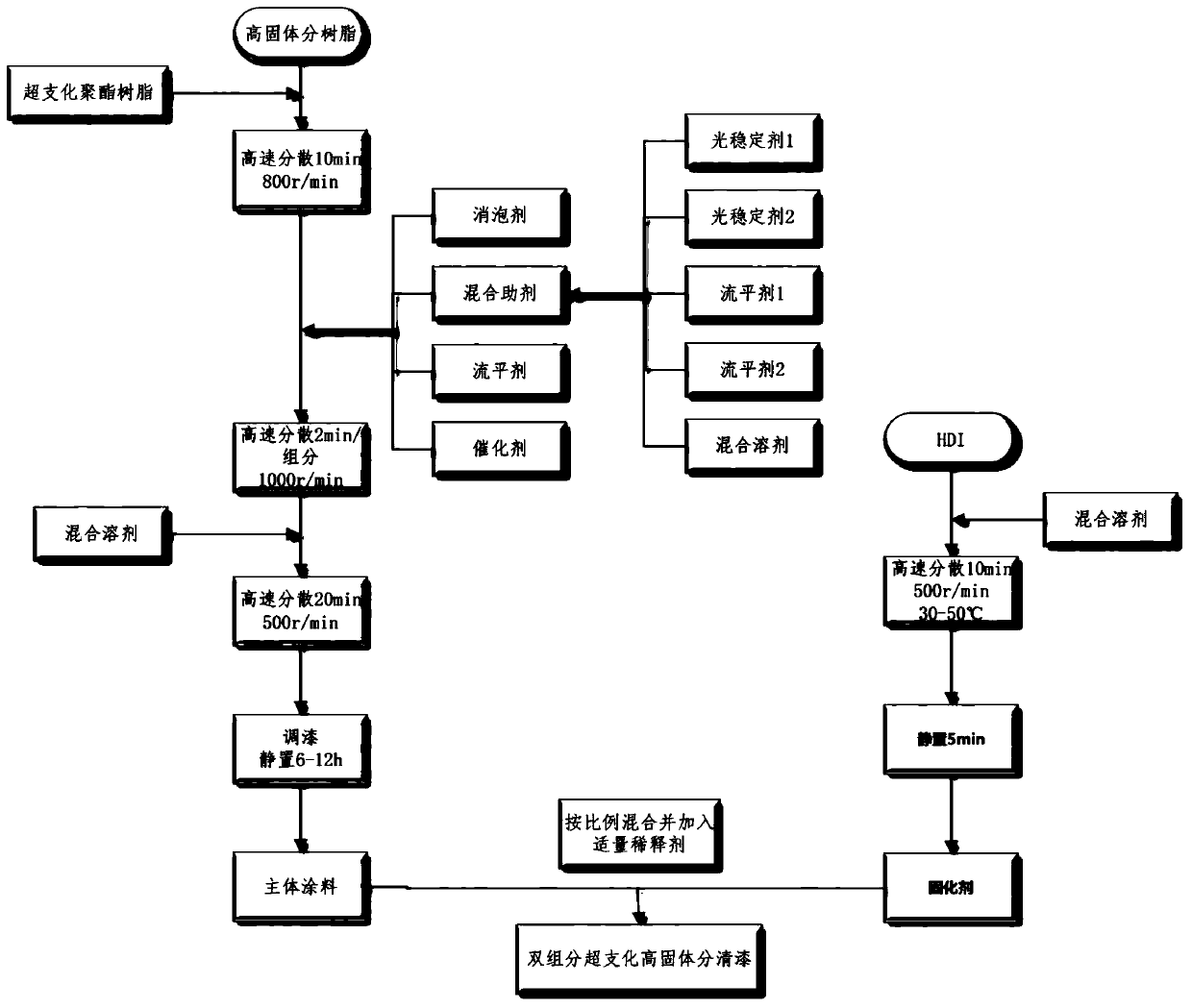

Method used

Image

Examples

Embodiment 1

[0048] (1) Weigh each component according to the table

[0049] Table 2: Example 1 component table

[0050]

[0051]

[0052] (2) Dispersion of ingredients: first slowly transfer the high-solid resin into the paint mixing tank, and then turn on the high-speed disperser at a speed of 800 rpm. Slowly pour the weighed hyperbranched polyester resin into the high-solid resin under high-speed stirring. Increase the speed at a constant speed to 1000 rpm. Cover and maintain the above speed for 10 minutes. Add defoamer, mixing aid, leveling agent and catalyst in sequence. Each time a component is added, maintain the rotation speed of 1000 rpm for 2 minutes before adding the next component. After gradually adjusting the rotation speed to 500 rpm, slowly add the mixed solvent, cover, and maintain the rotation speed at 500 rpm for 20 minutes.

[0053] Adjustment: Let the prepared main paint stand for 6 hours to eliminate most of the air bubbles, then pack it into metal barrels ...

Embodiment 2

[0057] (1) Weigh each component according to the table

[0058] Table 3: Example 2 component list

[0059]

[0060]

[0061] (2) with embodiment 1 step (2)

[0062] (3) When in use, the main paint and curing agent are mixed according to the following weight ratio, that is, main paint: curing agent = 100:66; the two components are mixed evenly to obtain the varnish. During construction, add appropriate amount of diluent to adjust to proper viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com