Processing technology for textile fabric capable of absorbing light in daytime and automatically emitting light at night

A technology of textile fabrics and processing technology, applied in the field of textile fabrics, can solve the problems of single function, practicability, and the appearance fails to achieve a better effect, and achieve the effect of high brightness, long luminous time, and clear boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

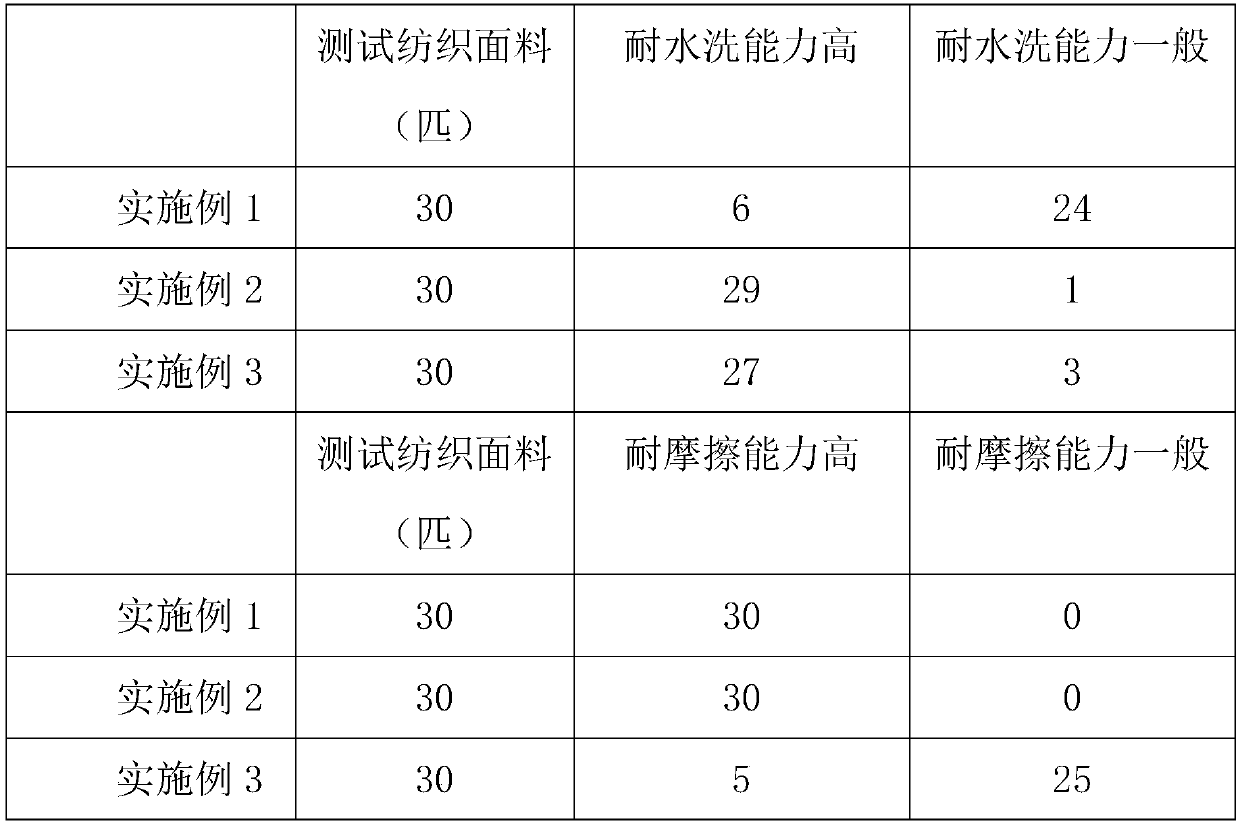

Embodiment 1

[0021] The invention provides a textile fabric processing technology that absorbs light during the day and automatically emits light at night, wherein the main materials used include the following raw materials in parts by weight: 5 parts of water-resistant PU, 2 parts of friction-resistant PU, 0.8 parts of high-temperature bridging agent, high-temperature promoting 0.3 parts of lubricant, 0.18 parts of slip agent, 2.8 parts of methyl ethyl ketone, 0.9 parts of DMF, 1.8 parts of high temperature resistant glass beads, 3.8 parts of solvent resistant luminous powder, and the balance is water. The specific processing steps are as follows:

[0022] Step 1: Add water-resistant PU, friction-resistant PU, high-temperature bridging agent, high-temperature accelerator, slip agent butanone, DMF, high-temperature-resistant glass beads, solvent-resistant luminous powder and water into a high-speed disperser, and stir for 3 minutes to form a slurry material;

[0023] Step 2: preparing the ...

Embodiment 2

[0028] The invention provides a textile fabric processing technology that absorbs light during the day and automatically emits light at night, wherein the main materials used include the following raw materials in parts by weight: 5.5 parts of water-resistant PU, 1.5 parts of friction-resistant PU, and 0.9 parts of high-temperature bridging agent 0.4 parts of high-temperature accelerator, 0.2 parts of slip agent, 3 parts of methyl ethyl ketone, 1 part of DMF, 2 parts of high-temperature resistant glass beads, 4 parts of solvent-resistant luminous powder, and the balance is water. The specific processing steps are as follows:

[0029] Step 1: Add water-resistant PU, friction-resistant PU, high-temperature bridging agent, high-temperature accelerator, slip agent butanone, DMF, high-temperature-resistant glass beads, solvent-resistant luminous powder and water into a high-speed disperser, and stir for 4 minutes to form a slurry material;

[0030] Step 2: preparing the textile fab...

Embodiment 3

[0035] The invention provides a textile fabric processing technology that absorbs light during the day and automatically emits light at night, wherein the main materials used include the following raw materials in parts by weight: 6 parts of water-resistant PU, 1 part of friction-resistant PU, 1 part of high-temperature bridging agent, high-temperature accelerator 0.5 parts of lubricant, 0.22 parts of slip agent, 3.2 parts of butanone, 1.1 parts of DMF, 2.2 parts of high temperature resistant glass beads, 4.2 parts of solvent resistant luminous powder, and the balance is water. The specific processing steps are as follows:

[0036] Step 1: Add water-resistant PU, friction-resistant PU, high-temperature bridging agent, high-temperature accelerator, slip agent butanone, DMF, high-temperature-resistant glass beads, solvent-resistant luminous powder and water into the high-speed disperser, and stir for 3-5 minutes form a slurry;

[0037] Step 2: preparing the textile fabric, ironi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com