Straw fiber stone composite ecological protection slope

A technology of straw fiber and ecological slope protection, applied in coastline protection, container cultivation, gardening, etc., to achieve the effect of preventing soil erosion, strong anti-scouring ability, and protecting the ecological environment of bank slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

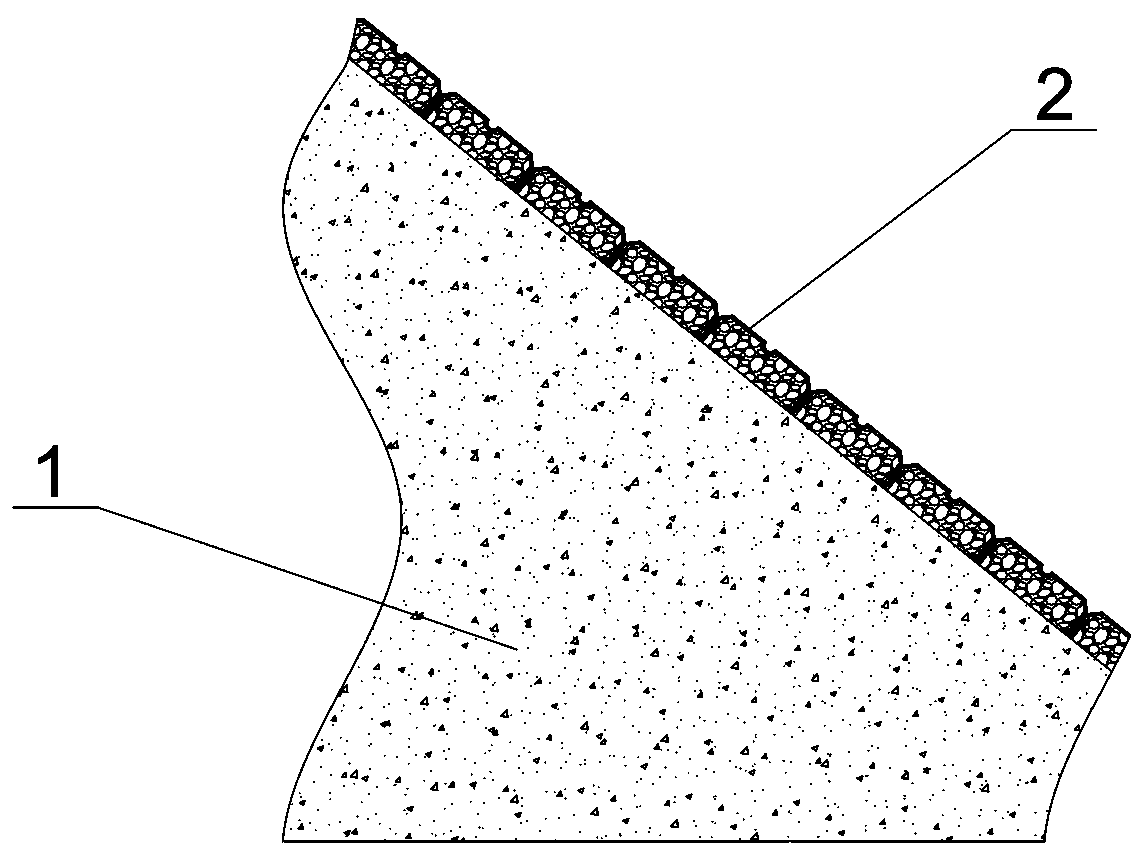

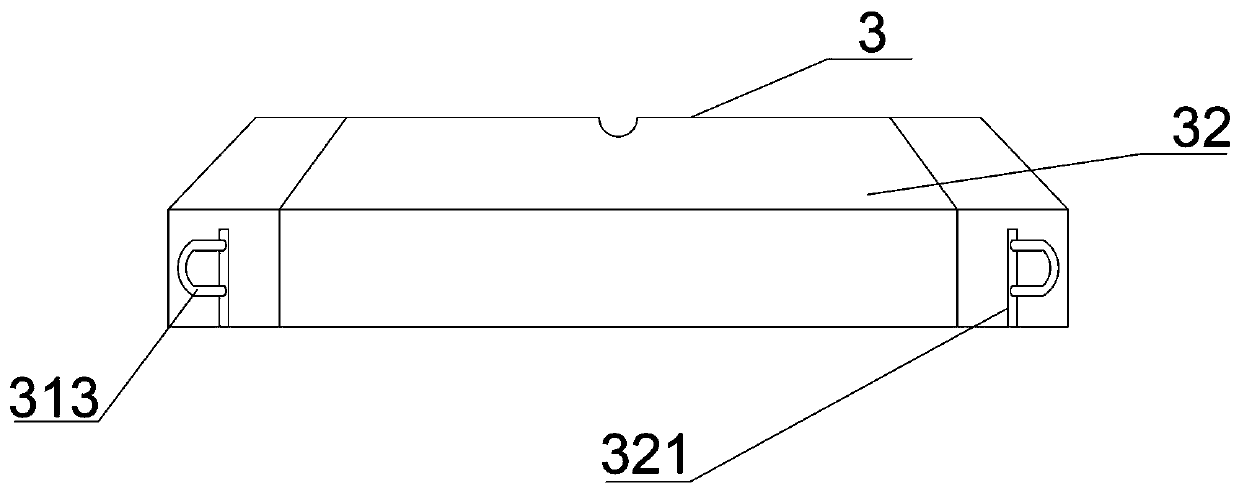

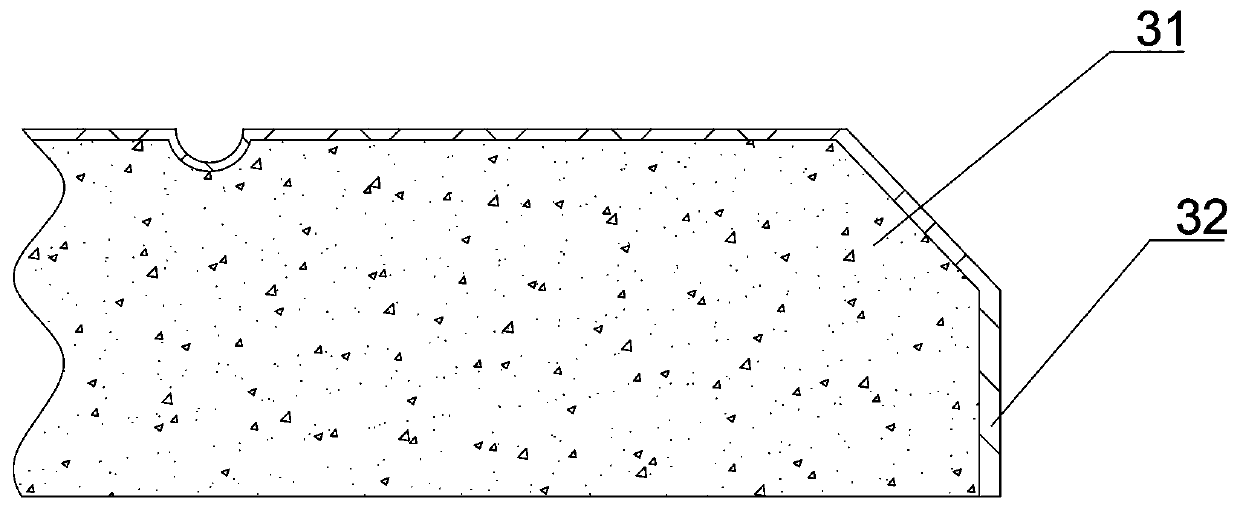

[0027] Such as figure 1 The present embodiment shown provides a kind of straw fiber stone composite ecological slope protection, including ecological slope protection 2 laid on the inclined bank slope 1 on both sides of the river, ecological slope protection 2 includes a plurality of straw fiber stone units 3 assembled and fixed together, straw The fiber stone unit 3 includes a main body block 31 and a shell-shaped greening induction layer 32 sleeved on the main body block 31 and conforming to the shape of the main body block 31 .

[0028] The main body block 31 is a horizontal rectangular parallelepiped porous concrete pouring block, and the porosity of the main body block 31 is 20%. The well-developed space in the main body block provides enough space for the growth of plant roots, and can The pores are filled with soil and fertilizers to provide the necessary nutrients for plant growth.

[0029] Such as Figure 4 , Figure 5 As shown, the four corners of the main body bl...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the main raw materials of the shell-shaped greening induction layer are different.

[0039] Such as figure 2 As shown, the main body block 31 is covered with a shell-shaped greening induction layer 32 that is inherently consistent with the shape of the main body block 31. The shell-shaped greening induction layer 32 is a shell made of straw fiber with a thickness of 2 cm. The shell-shaped greening induction layer 32 is mainly based on Corn stalks are processed as the main raw material. During processing, the corn stalks are first braided, then cellulose, water and other raw materials are added and injected into a mold that matches the main body block 31, and then heated and pressed to form a thickness It is a 2cm fiber shell, which is the shell-shaped greening induction layer 32 of the straw fiber stone unit. The strength of the shell-shaped greening induction layer 32 not only meets the requirements of the s...

Embodiment 3

[0041] Embodiment 3 Compared with Embodiment 1, the embedded parts that are flexibly and fixedly connected together through the connectors are all deeply fixed in the bank slope through anchor rods.

[0042] Such as figure 1 , Figure 8 As shown, after the adjacent straw fiber stone units 3 are flexibly and fixedly connected together by metal binding wires 4 to form the ecological slope protection 2, the embedded parts 313 at the four corners of the straw fiber stone units are deeply fixed on the In the bank slope 1, compared with embodiment 1, the ecological slope protection 2 of the present embodiment is more firmly fixed to the bank slope 1, so that the protection effect of the ecological slope protection 2 on the bank slope 1 is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com