Underground electromagnetic flaw detector

A flaw detector and electromagnetic technology, used in wellbore/well components, measurement, earthwork drilling and other directions, can solve the problems of low measurement accuracy and increase measurement time, so as to improve measurement accuracy, increase driving current, ensure Effects of Field Logging Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

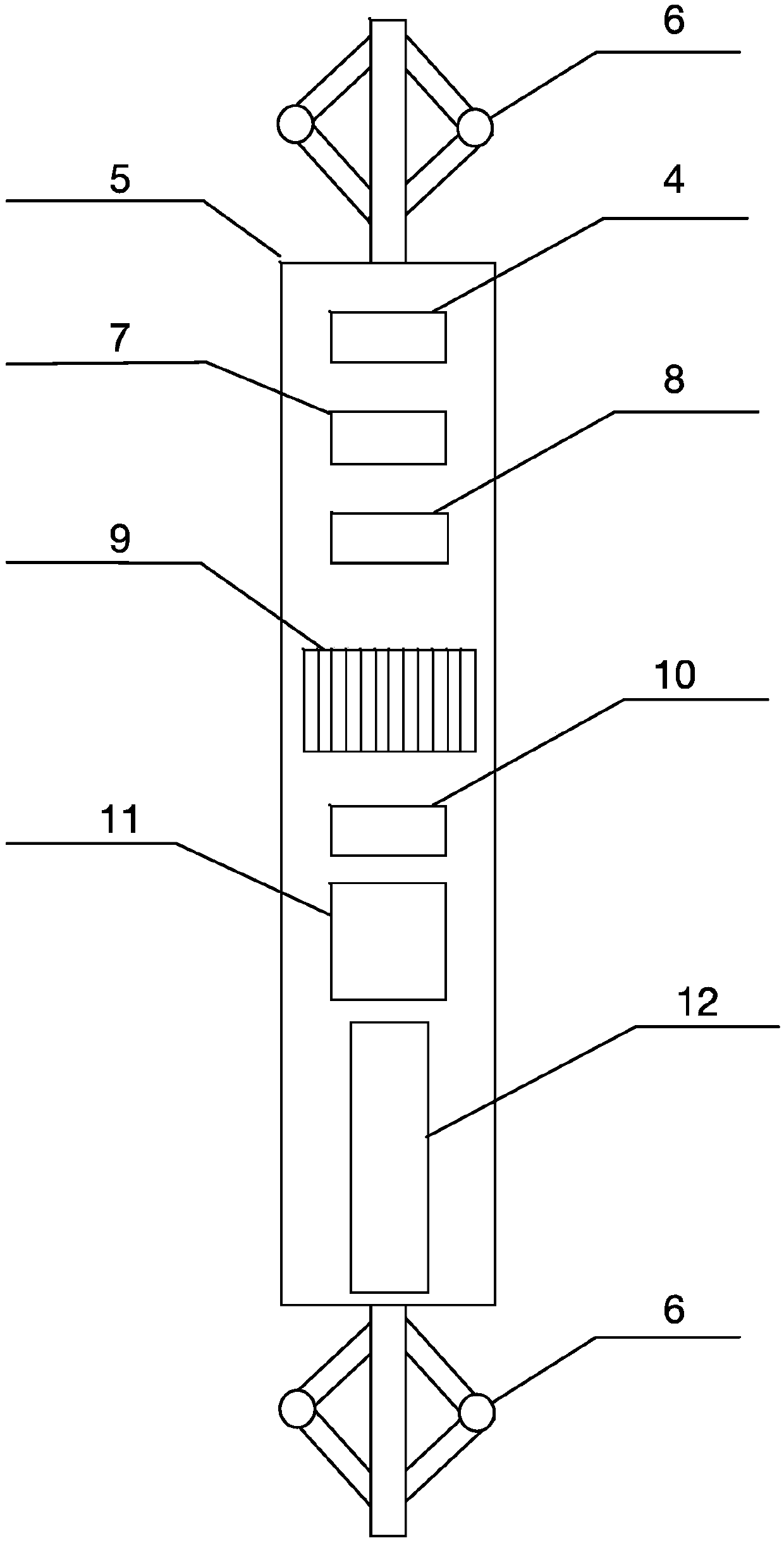

[0034] Embodiment of downhole electromagnetic flaw detector:

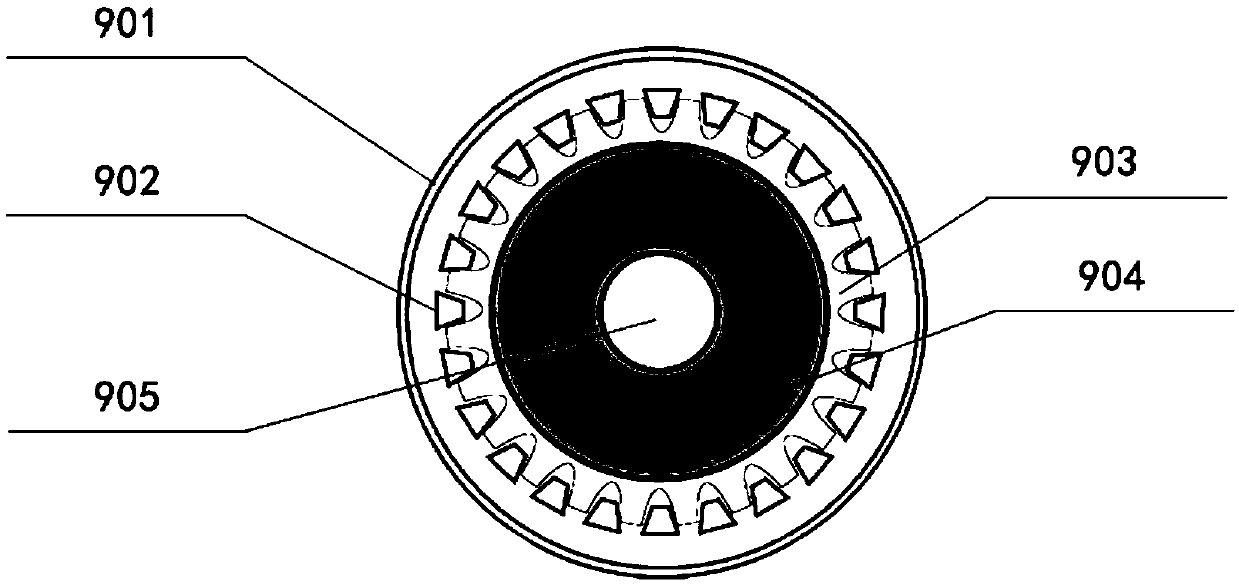

[0035] The main concept of the present invention is: the receiving system adopts a magnetic field array sensor, and each sensor in the magnetic field array sensor is connected to the processor module for receiving a common clock signal. When data collection is performed, the processor module sends a synchronous collection command to each sensor , Control each sensor to collect at the same time, synchronous acquisition can reduce the cycle time of a single measurement and improve the accuracy of instrument measurement.

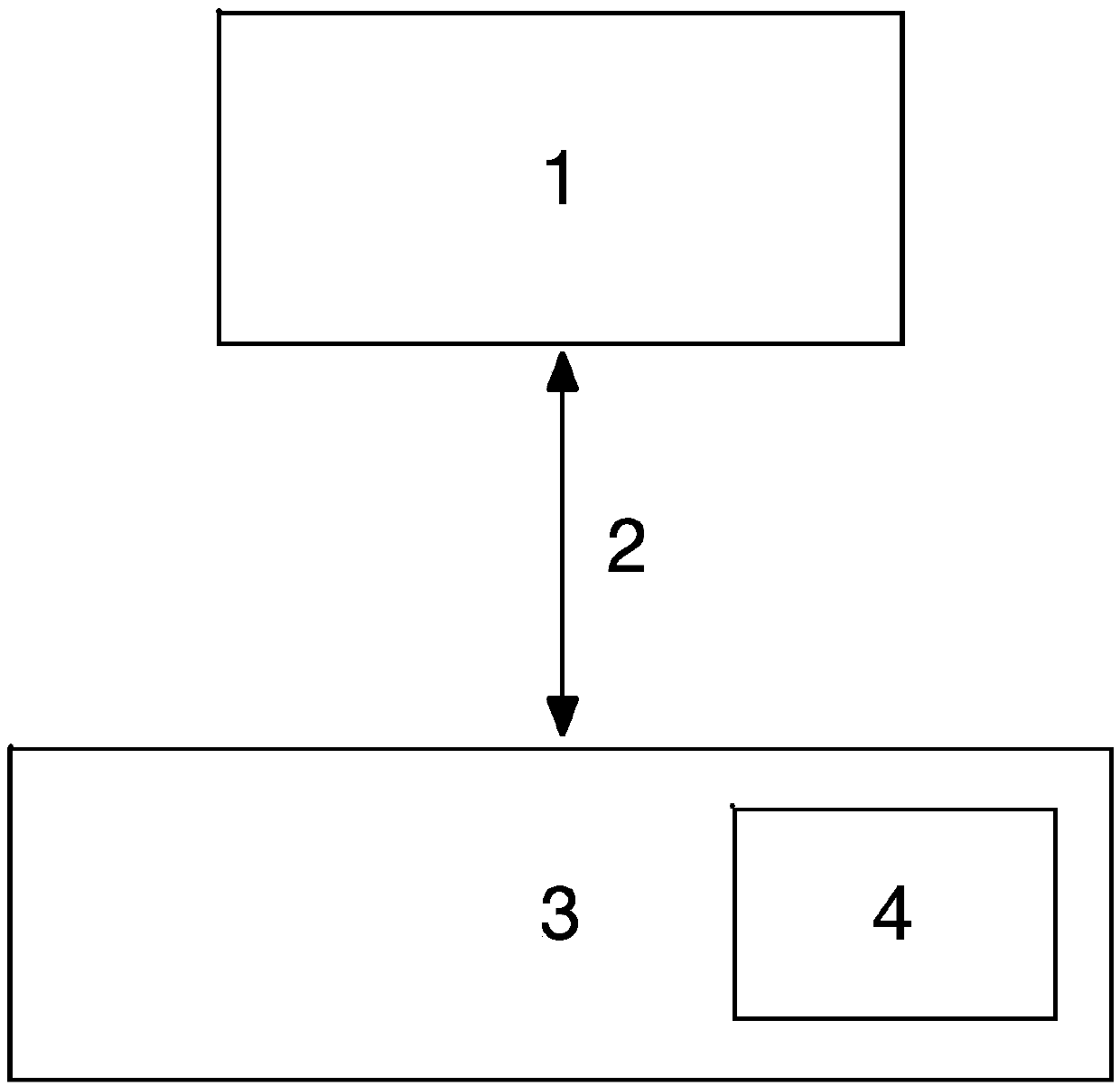

[0036] Such as figure 1 As shown, the DSP processor 4 (processor module) is built in the downhole electromagnetic flaw detector 3, and the collected information is uploaded to the upper computer 1 through the data power cable 2, and the upper computer 1 analyzes and processes the signal, and finally judges the production. Well casing integrity. Here we use the data power cable 2 for communication....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com