Floating oscillating water column type wave energy power generation device

An oscillating water column type, power generation device technology, applied in the directions of hydropower generation, ocean energy power generation, engine components, etc., can solve the problems of inconvenient disassembly and replacement, poor coordination, complex structure, etc., to prolong the service life and speed up the airflow. speed, the effect of reducing cable routing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

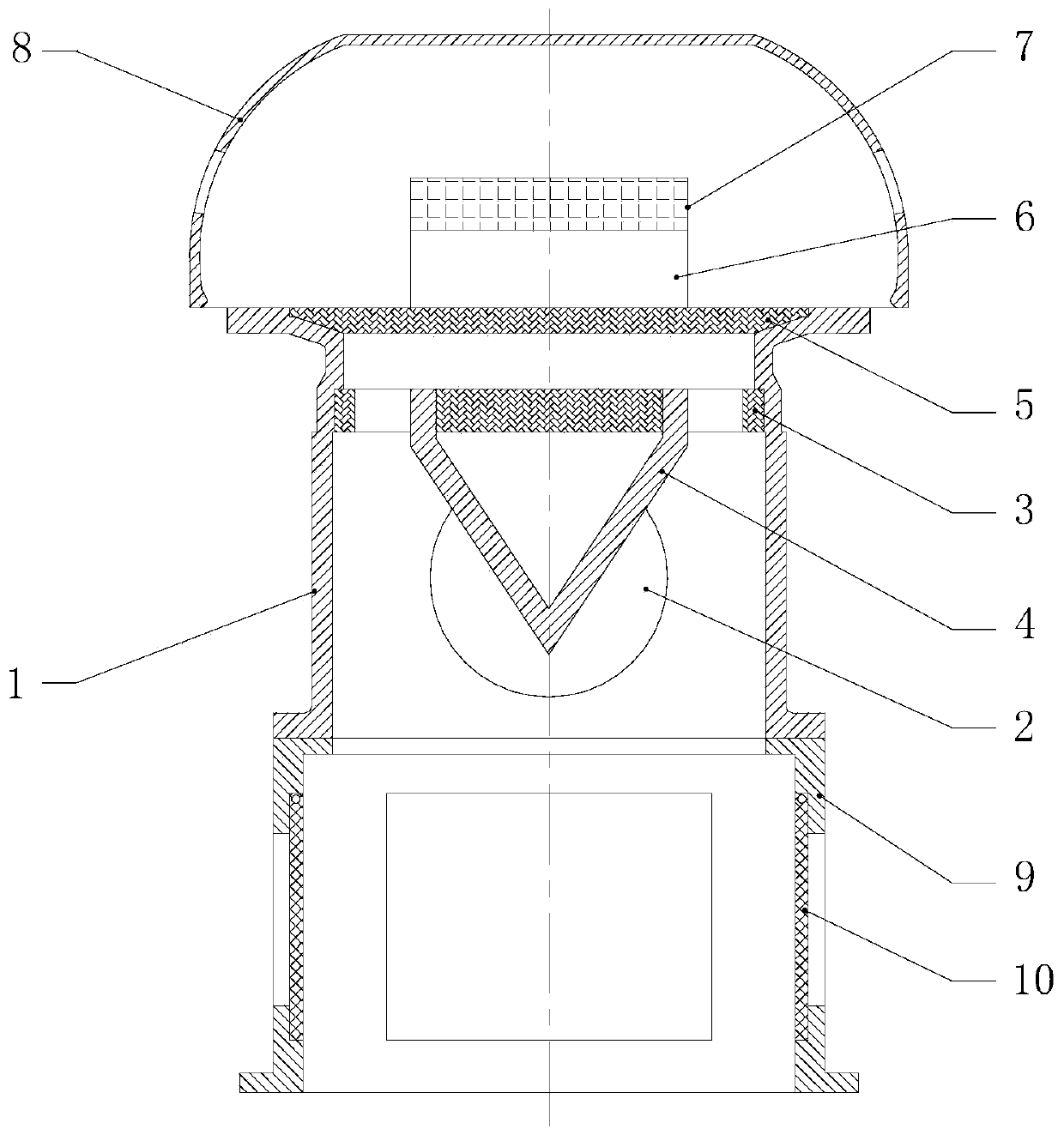

[0025] Such as figure 1 As shown, a floating oscillating water column type wave energy generating device includes a runner chamber 1 , a nozzle 3 , a diversion cone 4 , an impeller 5 , a generator 6 , a controller 7 and a protective cap 8 .

[0026] The runner chamber 1 is a cylindrical structure with a hollow interior, and a plurality of circular air valves 2 are arranged on the hub structure. Circular air valve 2 is made up of valve frame and valve, and valve can adopt soft material, for example, rubber sheet, is installed on the top of valve frame, and valve can only do opening and closing movement inwardly, is used in runner chamber-1. Air is replenished during pressing, and the specific opening and closing structure can adopt a conventional hinged joint method, which will not be repeated here.

[0027] The nozzle 3 is installed in the middle and upper part of the runner chamber-1, above the circular air valve 2, and is used to accelerate the air extruded into the runner ...

Embodiment 2

[0034] On the basis of embodiment 1, the runner chamber two 9 is added. Specifically, the runner chamber two 9 is installed directly below the runner chamber one 1, and the two are sealed by rubber. The second runner chamber 9 is a cuboid or cube structure, and the interior is hollow. There is a rectangular air valve 10 at the center of each vertical surface of the cube runner chamber 9; the rectangular air valve 10 is composed of a valve frame and a valve, and the valve adopts soft It is installed on the top of the valve frame, and the valve can only open and close inwards. The specific structure is the same as that of the circular air valve 2.

[0035] It should be noted that although Embodiment 1 uses a cylindrical runner chamber, it can be replaced with the square runner chamber of Embodiment 2 through a simple design. In this way, the floating oscillating water column type wave energy power generation The device can adopt different runner chambers according to different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com