Pump of washing device

A washing device and pump cavity technology, which is applied in the field of the pump of the washing device, can solve the problems of excessive space occupied by heating components, influence of the life of the heating tube, poor flow uniformity, etc., and achieves improved user experience, compact structure, and uniform thermal stress coupling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

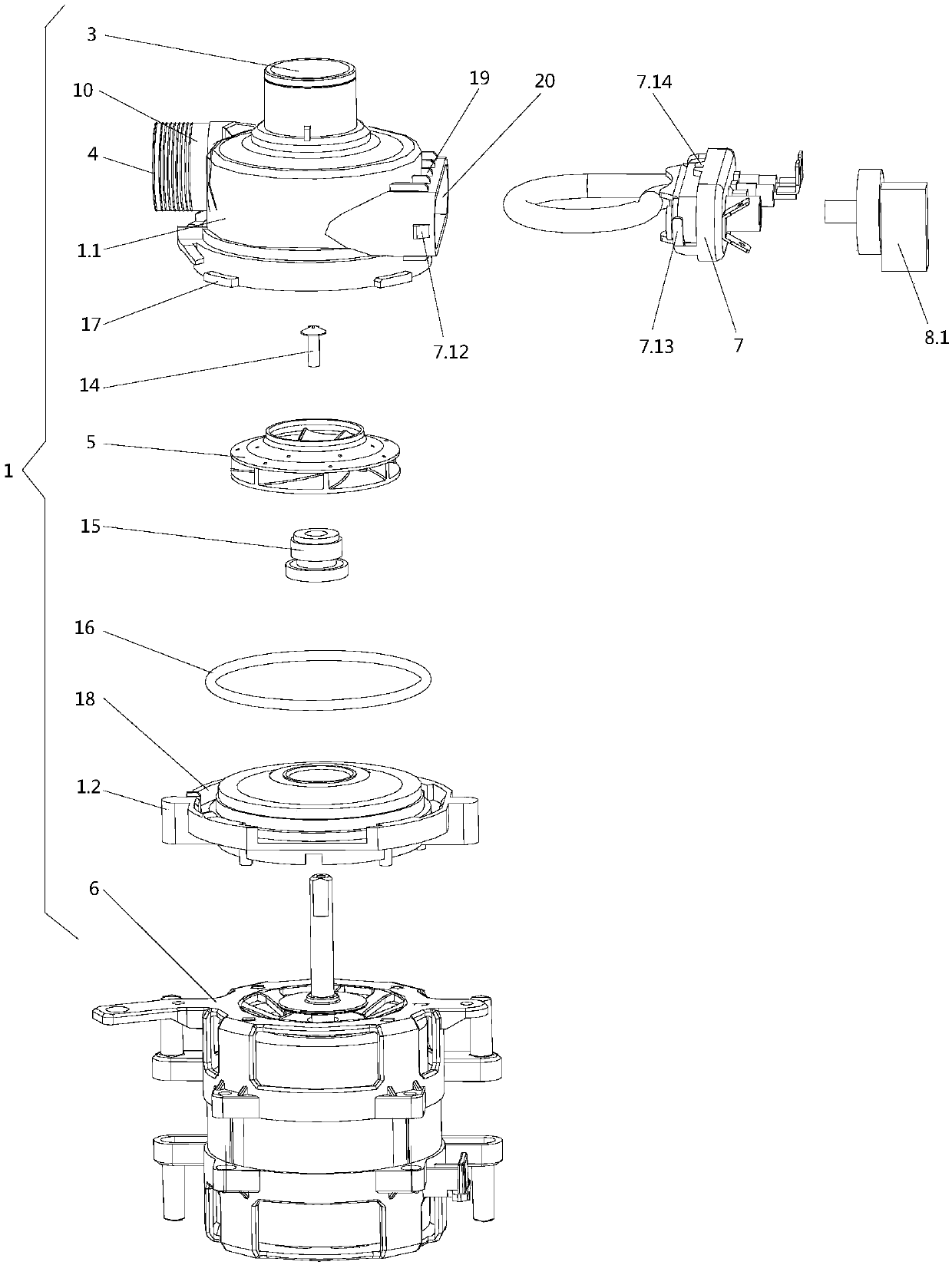

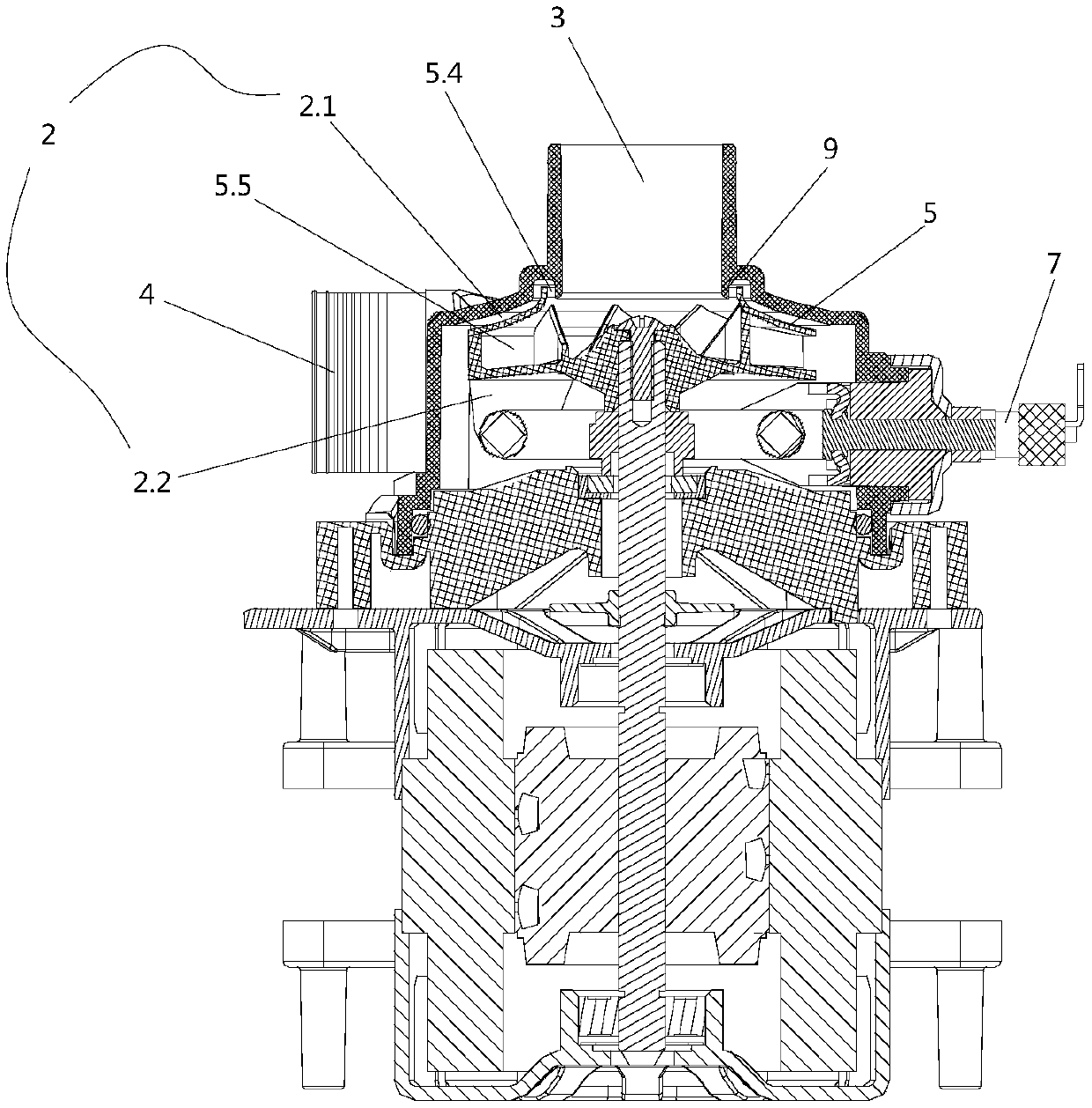

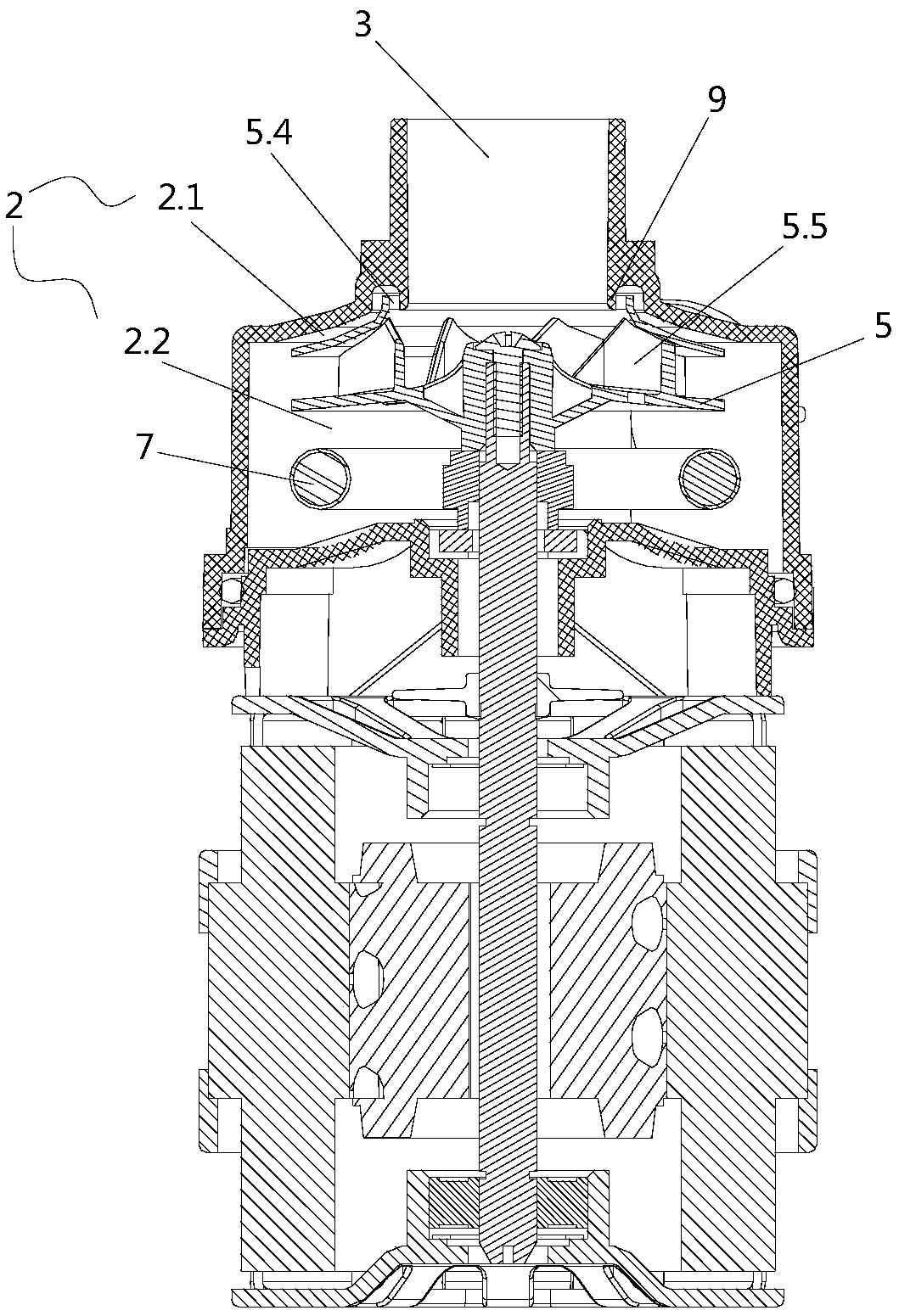

[0106] like Figure 1 to Figure 13 As shown, the pump of a washing device described in this embodiment includes a pump body 1; the pump body 1 is provided with a pump chamber 2 for containing liquid; the pump body 1 is provided with a liquid inlet communicating with the pump chamber 2 Port 3 and liquid outlet 4; the pump chamber 2 is provided with an impeller 5 connected to the motor 6 through a rotating shaft; it also includes a heating device extending from the outside of the pump body 1 to the pump chamber 2 to heat the liquid in the pump chamber 2 Assembly 7; set on the pump body 1, the first pressure switch 8.1 connected to the heating assembly 7; the impeller 5 divides the pump chamber 2 into the first chamber 2.1 close to the liquid inlet 3 and the second chamber 2.1 away from the liquid inlet 3 The chamber 2.2 and the heating assembly 7 are set in the second chamber 2.2. When the liquid flows into the pump chamber 2 through the liquid inlet 3, it flows through the impe...

Embodiment 2

[0108] like Figure 1 to Figure 13 As shown, this embodiment is a further limitation of the first embodiment above. In the pump of a washing device described in this embodiment, the projection of the liquid outlet 4 in the pump chamber 2 at least covers the impeller 5 and part The heating component 7, by covering the impeller 5 and the setting of the heating component 7, enables the deposition liquid in the second chamber 2.2 to be effectively circulated, avoiding excessive deposition of liquid in the second chamber 2.2 causing poor circulation of the flow area , and then affect the use of the pump body 1.

Embodiment 3

[0110] like Figure 4 and Figure 5 As shown, this embodiment is a further limitation of the above-mentioned embodiment 1 or embodiment 2. In the pump of a washing device described in this embodiment, the heating assembly 7 includes a heating tube 7.1 and is arranged inside the heating tube 7.1. The fuse and heating wire; set in sequence and cooperate with the nut 7.3 through the passing bolt 7.2 to realize the first heating unit 7.4, the second heating unit 7.5 and the third heating unit 7.6 connecting the heating pipe 7.1 to the pump body 1, and re- The connection mode between the heating assembly 7 and the pump body 1 is defined, so that the heating assembly 7 is subjected to clamping force inside and outside the pump body 1, which improves the sealing performance of the device, and also makes the disassembly, repair, maintenance, and maintenance of the heating assembly 7 easy. The replacement of the pressure switch has been improved, enhancing the user experience.

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com