Liquefied natural gas storage tank BOG recovery system

A technology of liquefied natural gas and recovery system, applied in the field of BOG recovery system of liquefied natural gas storage tank, can solve problems such as waste and economic loss of owners, and achieve the effect of eliminating dependence on external power and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

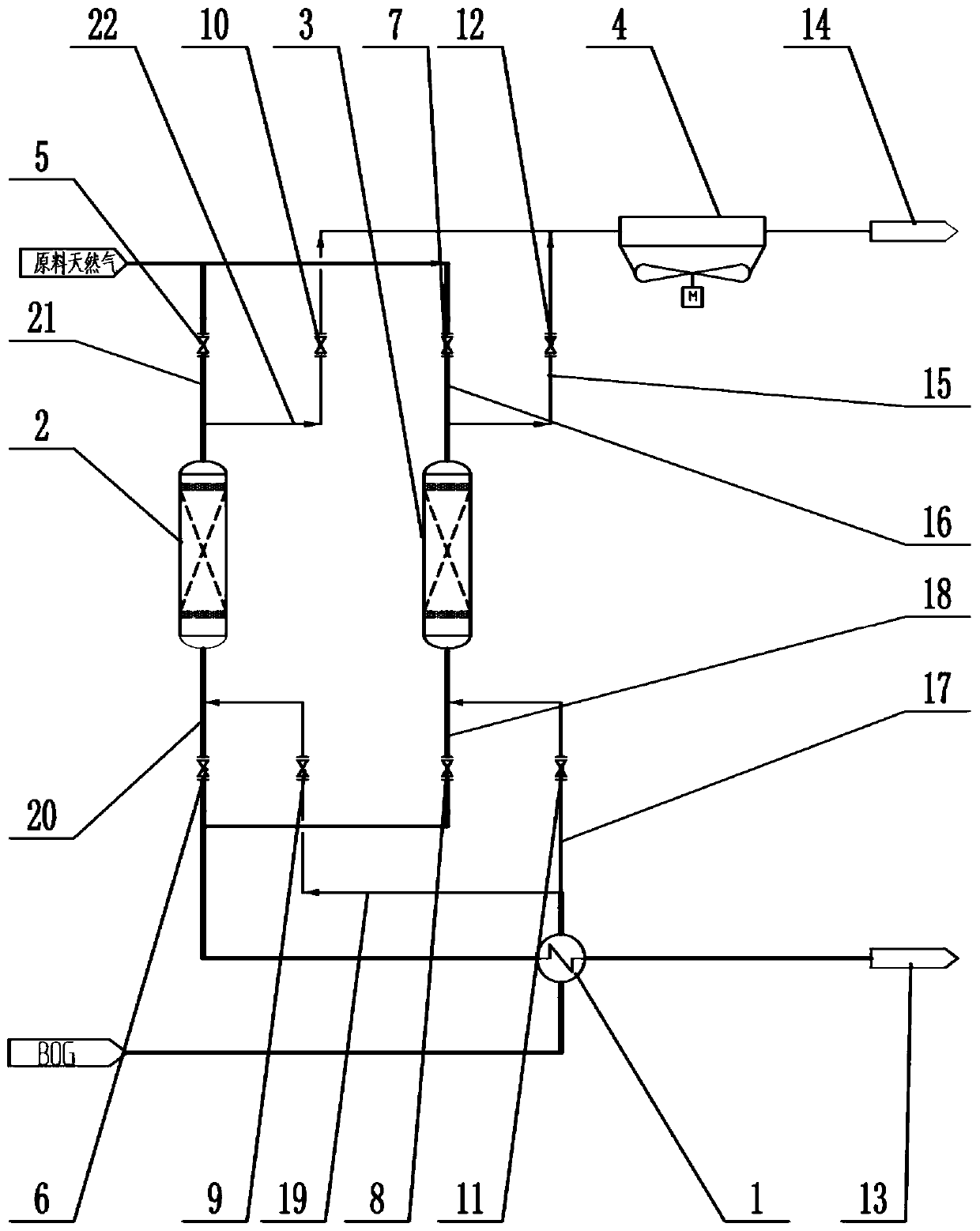

[0013] A BOG recovery system for a liquefied natural gas storage tank, including a natural gas purification tower, an air cooler 4, a purified natural gas precooling heat exchanger 1, and a gas generator 14. The raw natural gas is connected to the natural gas purification tower through pipelines, and the natural gas purification tower is passed through pipelines Connect the purified natural gas precooling heat exchanger 1 for precooling the purified natural gas, and the purified natural gas precooling heat exchanger 1 is transported to the cold box 13 for deep cooling through pipelines to form a purification system; the purified natural gas precooling heat exchanger 1 cools The source is BOG, and the purified natural gas pre-cooling heat exchanger 1 is connected to the natural gas purification tower through pipelines. BOG is used as the cold blowing raw material gas in the regeneration process. The natural gas purification tower is connected to the air cooler 4 of the regenerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com