Direct expansion type ground source heat pump refrigerant leakage-proof device and method thereof

A leak-proof device and refrigerant technology, applied in refrigerators, refrigeration components, measuring devices, etc., can solve the problem that the buried heat exchanger cannot be installed with detectors, the stability and safety of the unit are affected, and the flowmeter cannot be accurately measured, etc. To solve the problem, to achieve the effect of convenient and accurate refrigerant flow measurement, reduce the impact of stability and safety, and solve the difficulty of oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

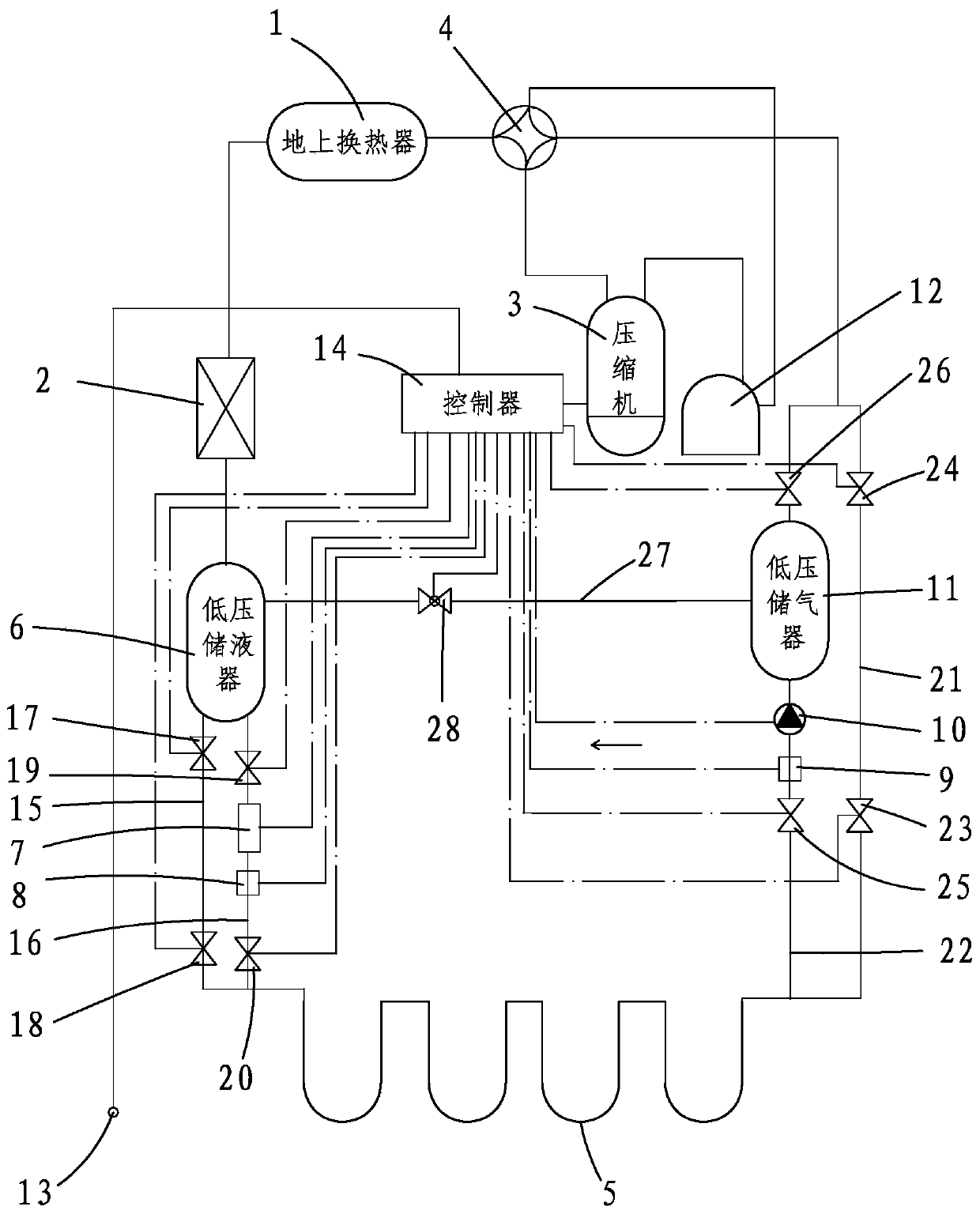

[0043] refer to Figure 1-2 , the present invention relates to a direct expansion ground source pump refrigerant leakage prevention device, including an aboveground heat exchanger 1, a throttle valve 2, a compressor 3, a four-way reversing valve 4, a buried heat exchanger 5, a low pressure storage Liquid container 6, electric heater 7, first flow meter 8, second flow meter 9, refrigerant pump 10, low-pressure gas receiver 11, gas-liquid separator 12, temperature sensor 13 and controller 14;

[0044] The ground heat exchanger 1 is connected to the low-pressure liquid reservoir 6 through the throttle valve 2, and the two outlets of the low-pressure liquid reservoir 6 are respectively connected to the buried heat exchange through the first heat exchange pipe 15 and the first detection pipe 16. One end of the device 5 is connected, the first heat exchange tube 15 is sequentially provided with a first solenoid valve 17 and a second solenoid valve 18, and the first detection tube 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com