Model predictive torque control method for npc three-level converter-pmsm system

A technology for predicting torque and control methods, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problems of not considering the impact and not being able to directly apply the model predictive torque control algorithm, etc., to achieve improved Effects of control performance, shorter holddown times, and simplified method handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0041] Embodiments of the present invention and its implementation work process are as follows:

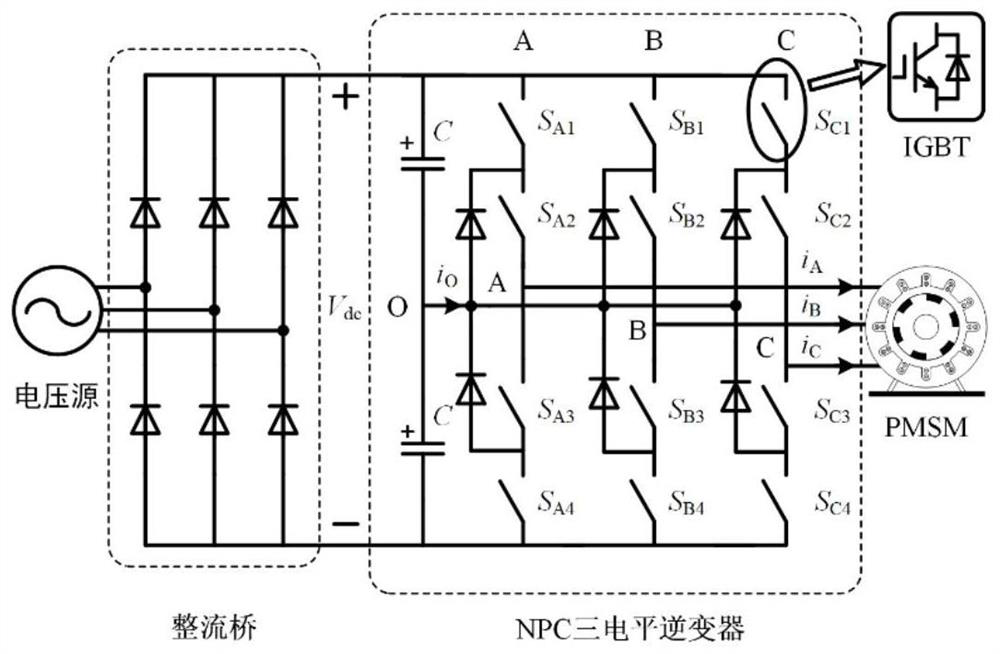

[0042] The specific implementation of the NPC three-level converter-PMSM system structure is as follows: figure 1 As shown, the NPC three-level converter-PMSM system includes a voltage source, a rectifier bridge, an NPC three-level converter and a permanent magnet synchronous motor; the rectifier bridge is composed of three groups of diode groups connected in parallel, and each group of diodes The group is composed of two diodes in series, and the connection between the two diodes of the three groups of diodes is connected to the voltage source; the three groups of diodes are connected in parallel to output the rectified voltage V dc ;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com