Cabinet and server cooling device

A technology for cooling devices and servers, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., and can solve problems such as poor cooling uniformity of servers, inability to adapt flexibly to cabinets, and inability to adapt flexibly to server cooling devices. Achieve the effect of improving cooling uniformity and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

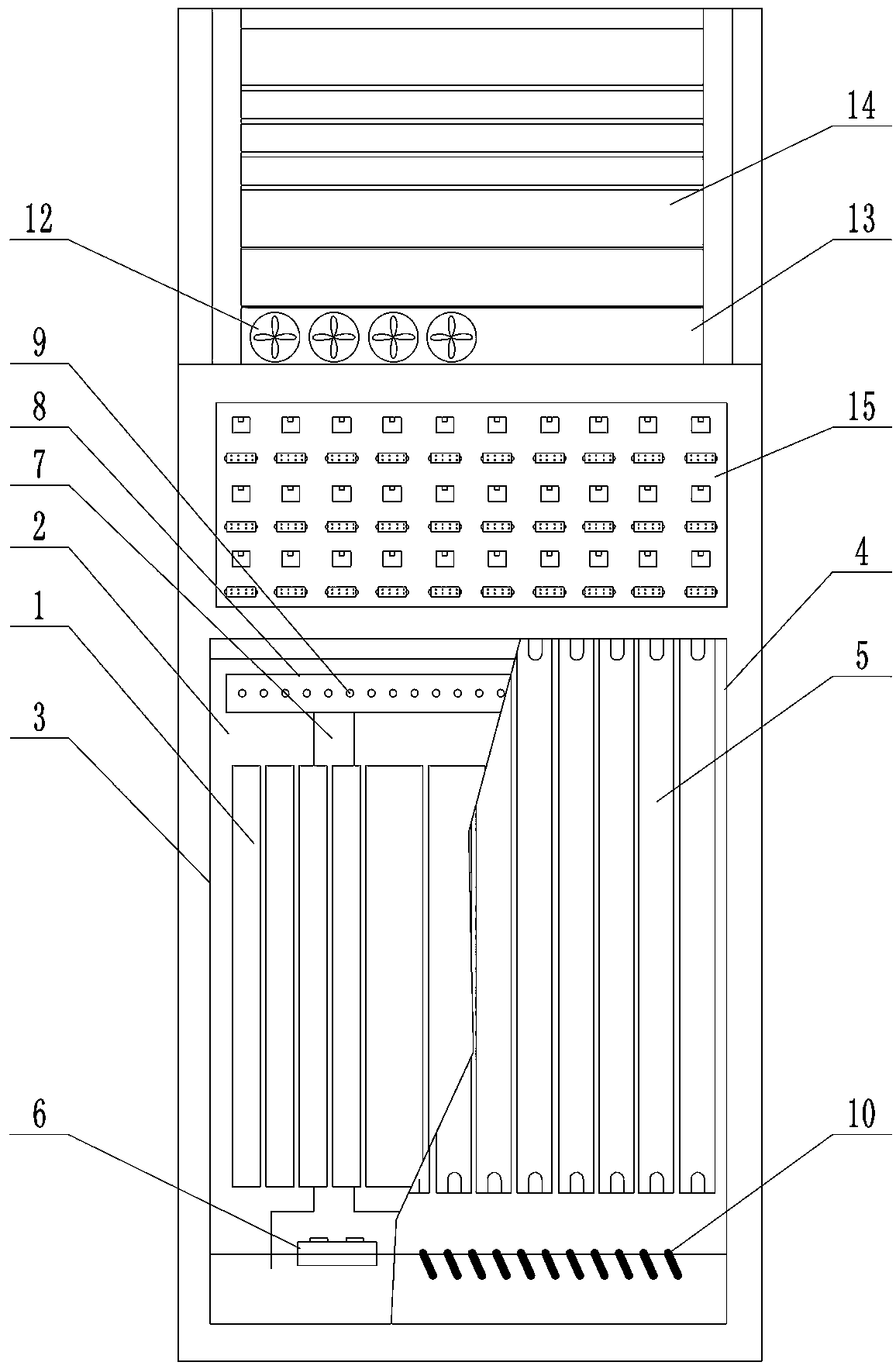

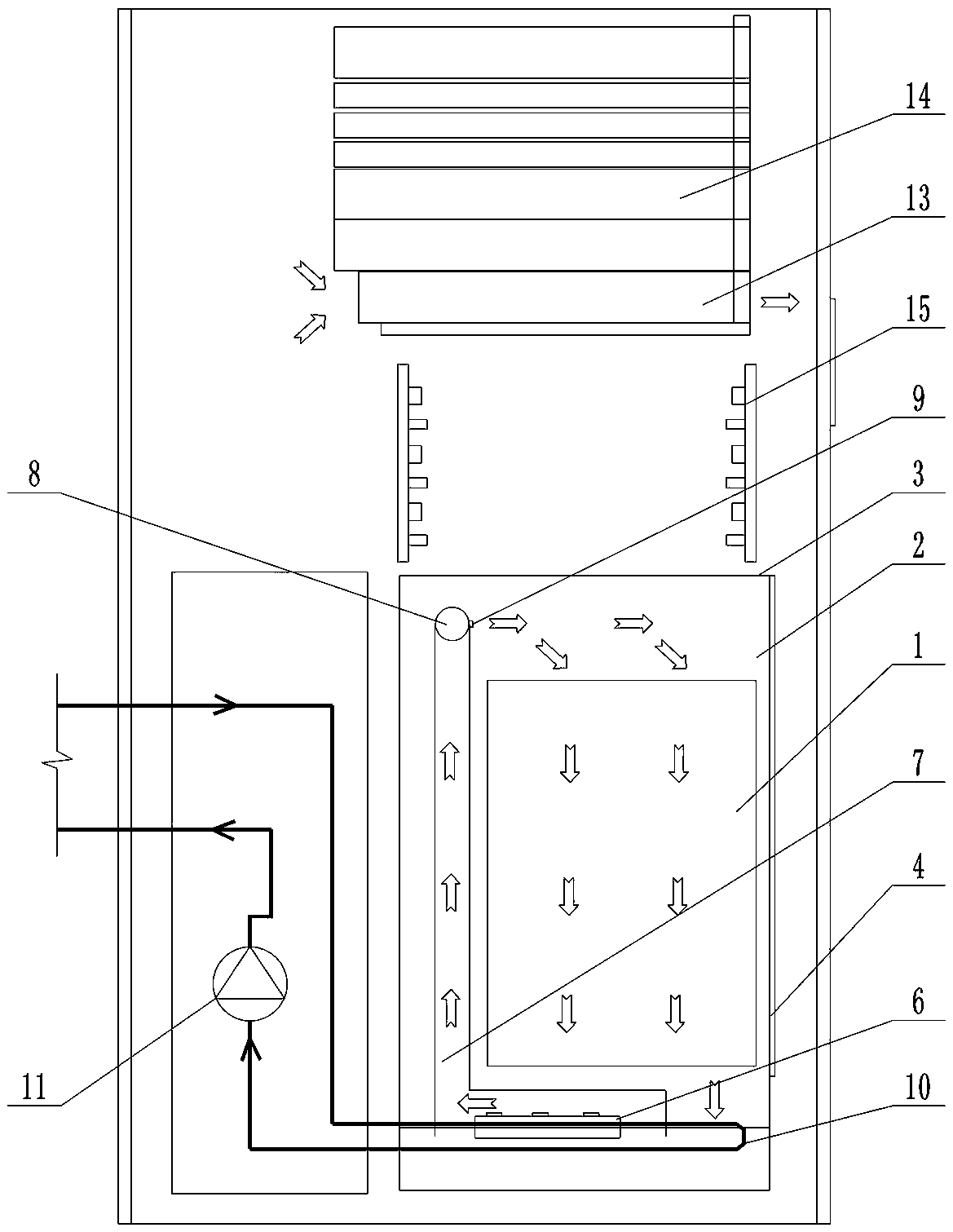

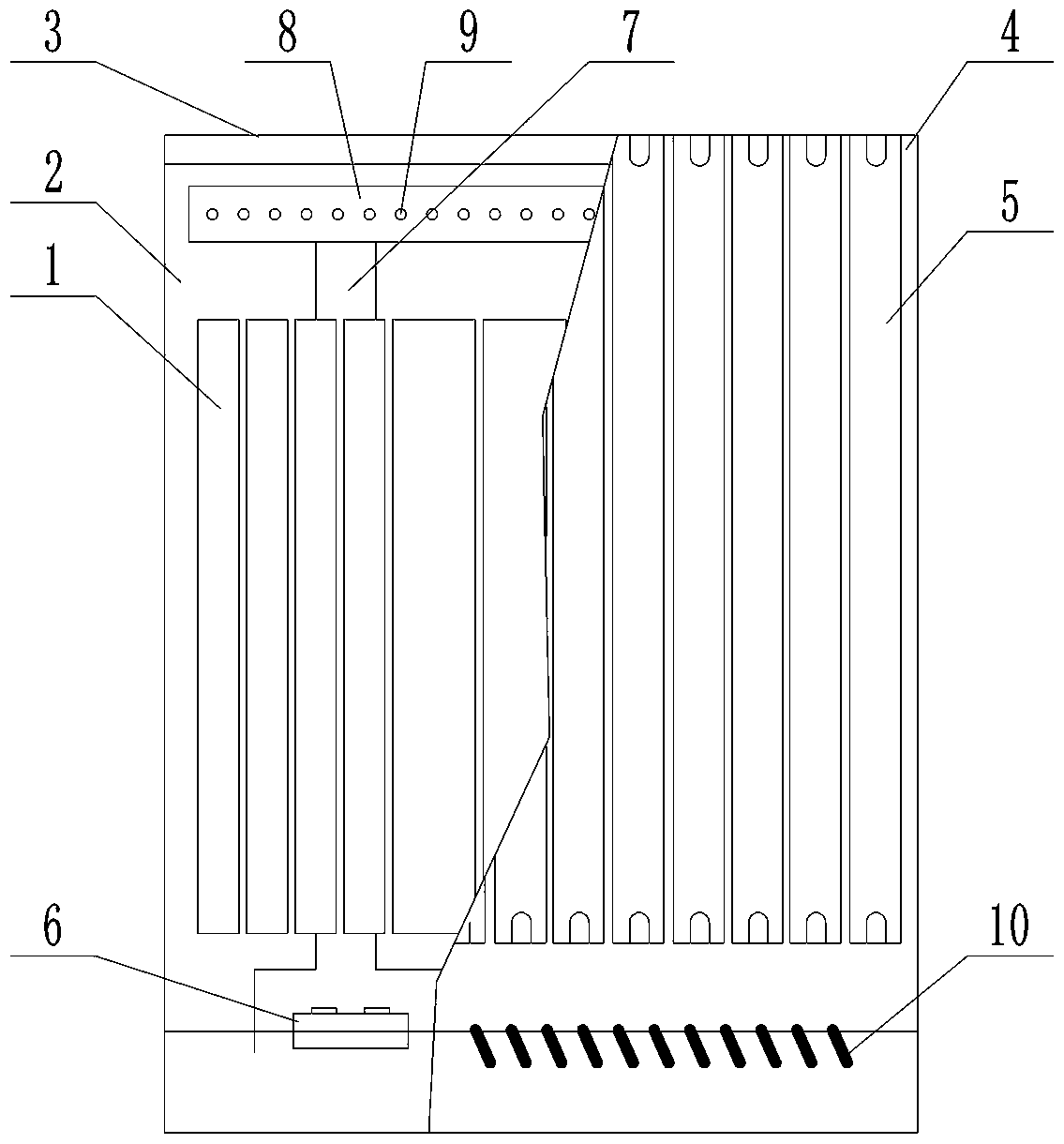

[0037] Such as figure 1 As shown, the cabinet includes a cabinet body, and a server 1 , a cooling medium, and a server cooling device for cooling the server 1 through the cooling medium are arranged in the cabinet. In this example, if Figure 1 to Figure 4 As shown, the server cooling device includes a fog cooling chamber 2. The fog cooling chamber 2 includes a chamber body 3 and a chamber door 4. The chamber door 4 is sealed and installed on the front side of the chamber body 3. The chamber door 4 includes 12 strip-shaped sealing plates 5 , there are 12 servers 1 placed in the fog cold chamber 2, and the 12 servers 1 are placed upright in the fog cold chamber 2 at intervals, and each server 1 is arranged corresponding to the width and position of the strip-shaped sealing plate 5 on the front side, each Each strip-shaped sealing plate 5 can be disassembled or installed independently, so as to facilitate the installation, maintenance and disassembly of each server 1.

[0038]...

specific Embodiment 2

[0051] It differs from Embodiment 1 in that: as Figure 5 As shown, no cooling device, cooling fan and heating parts are arranged in the cabinet, the circulation pump is arranged outside the cabinet, the cabinet is a sealed cabinet, the cabinet forms a fog cold storehouse 16, and the cabinet door is the door 17 of the fog storehouse 16, Servers 18 are arranged at intervals in the mist cooling chamber 16 along the up and down direction, and the conveying pipe 19 is extended and arranged along the up and down direction. The conveying pipe 19 is provided with spray holes facing the direction of the servers horizontally. The cooling medium is single-phase cooling liquid. The cooling working fluid is output from the spray hole 20 and enters into the server 18 to cool the heat-generating components in the server 18 .

[0052] In this embodiment, the atomized cooling medium has better diffusivity, and can be adapted to the arrangement of servers arranged at intervals along the vertic...

specific Embodiment 3

[0056] The difference from Example 1 is that the cooling medium is a phase-change cooling medium, and the specific cooling medium is a fluorinated liquid. The atomized fluorinated liquid enters the server and contacts the heat-generating components of the server. During the heat exchange process of the components, the fluorinated liquid is vaporized, and the vaporized fluorinated liquid flows downward along with the atomized fluorinated liquid entering the server to enter the fluorinated liquid stored at the bottom of the mist cold chamber. In the liquid, under the action of the cooling coil, the vaporized fluorinated liquid releases heat to form a liquid, which is re-atomized by the atomizer for the next cycle.

[0057] In this embodiment, in order to improve the cooling efficiency of the server, the fan in the server can be used to increase the flow speed of the vaporized fluorinated liquid in the server.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com