A kind of method of using silt and construction waste to prepare porous planting solidified soil

A technology of construction waste and solidified soil, which is applied in botany equipment and methods, planting substrates, applications, etc., can solve the problems of aggravating the difficulty of environmental governance and potential safety hazards, and achieve environmental protection, reduce processing costs, and good pressure resistance The effect of strength and vegetativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

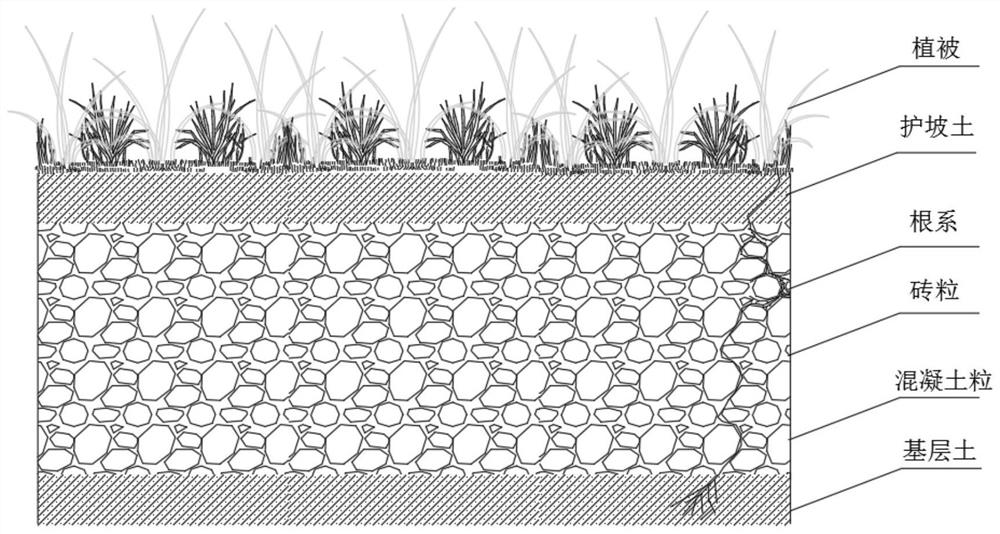

[0025] Take the Qinhuai River (Qiqiao Weng Ecological Wetland Park Section) mud pretreatment in Nanjing City, Jiangsu Province to remove large particles and dewater. After pretreatment, the water content of the mud is 55%, and then add the following parts by weight in the mud after per 1000 parts by weight of pretreatment Additives: 15 parts of metakaolin, 15 parts of slag powder, 10 parts of water glass, 20 parts of fertilizer (vermicompost, organic matter content 40%), 10 parts of humic acid, 20 parts of sulfonated oil, 15 parts of polyvinyl acetate, 15 parts of anionic polyacrylamide and 550 parts of water are mixed to obtain soil sludge, which is used as slope protection soil. The construction waste is crushed and sieved, and the bricks and concrete blocks are screened as aggregates. The aggregate particle size is 9.5-16 mm. figure 1 As shown in the basic structure, the bottom layer is base soil, the middle layer is brick particles and concrete, and the upper layer is soil...

Embodiment 2

[0028] Take the Qinhuai River (Qiqiao Weng Ecological Wetland Park Section) mud pretreatment in Nanjing City, Jiangsu Province, remove large particles and dewater, after pretreatment, the water content of the mud is 55%, and then add the following parts by weight in the mud after per 1000 parts by weight of pretreatment Additives: 10 parts of metakaolin, 10 parts of slag powder, 5 parts of water glass, 15 parts of fertilizer (vermicompost, organic matter content 40%), 10 parts of humic acid, 20 parts of sulfonated oil, 15 parts of polyvinyl acetate, anion 15 parts of polyacrylamide and 550 parts of water are mixed to obtain soil sludge, which is used as slope protection soil. The construction waste is crushed and sieved, and the bricks and concrete blocks are screened as aggregates. The aggregate particle size is 9.5-16 mm. figure 1 As shown in the basic structure, the bottom layer is base soil, the middle layer is brick particles and concrete, and the upper layer is soil silt...

Embodiment 3

[0031] Take the Qinhuai River (Qiqiao Weng Ecological Wetland Park Section) mud pretreatment in Nanjing City, Jiangsu Province, remove large particulate matter and dewater, the pretreatment mud water content is 55%, and then add the following weight parts additives in the mud after per 1000 weight parts pretreatment : 15 parts of metakaolin, 15 parts of slag powder, 10 parts of water glass, 20 parts of fertilizer (vermicompost, organic matter content 40%), 15 parts of humic acid, 25 parts of sulfonated oil, 20 parts of polyvinyl acetate, anionic poly 20 parts of acrylamide and 550 parts of water are mixed to obtain soil sludge, which is used as slope protection soil. The construction waste is crushed and sieved, and the bricks and concrete blocks are screened as aggregates. The particle size of the aggregates is 4.75-9.5 mm. figure 1 As shown in the basic structure, the bottom layer is base soil, the middle layer is brick particles and concrete, and the upper layer is soil sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com