Kernel-hull separating system of sunflower seeds

A kernel-shell separation and sunflower seed technology, applied in the field of sunflower seed kernel-shell separation system, can solve problems such as failure to meet the target ratio, decline in production and processing economic indicators, and affect the quality of sunflower oil, so as to improve economic benefits, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

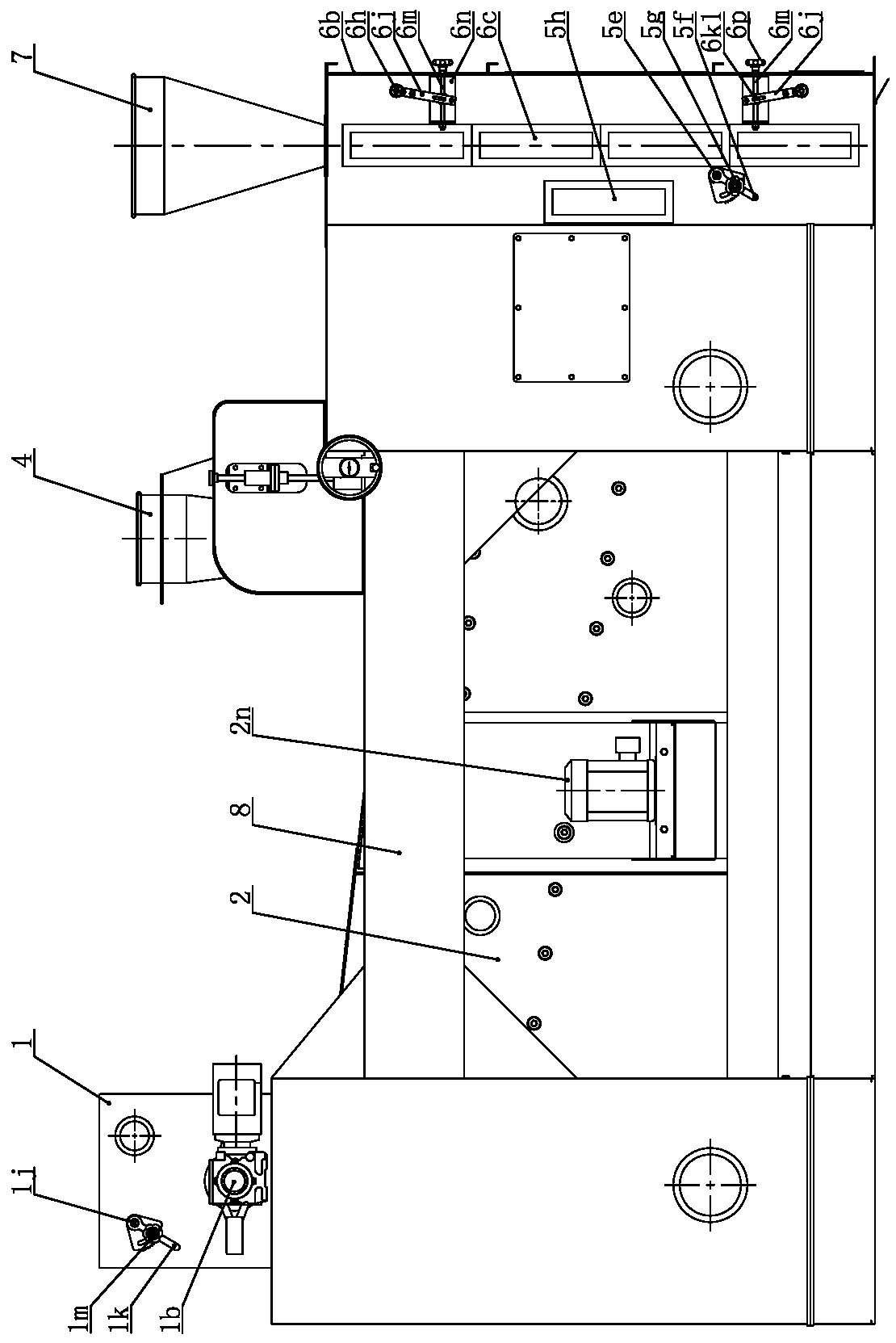

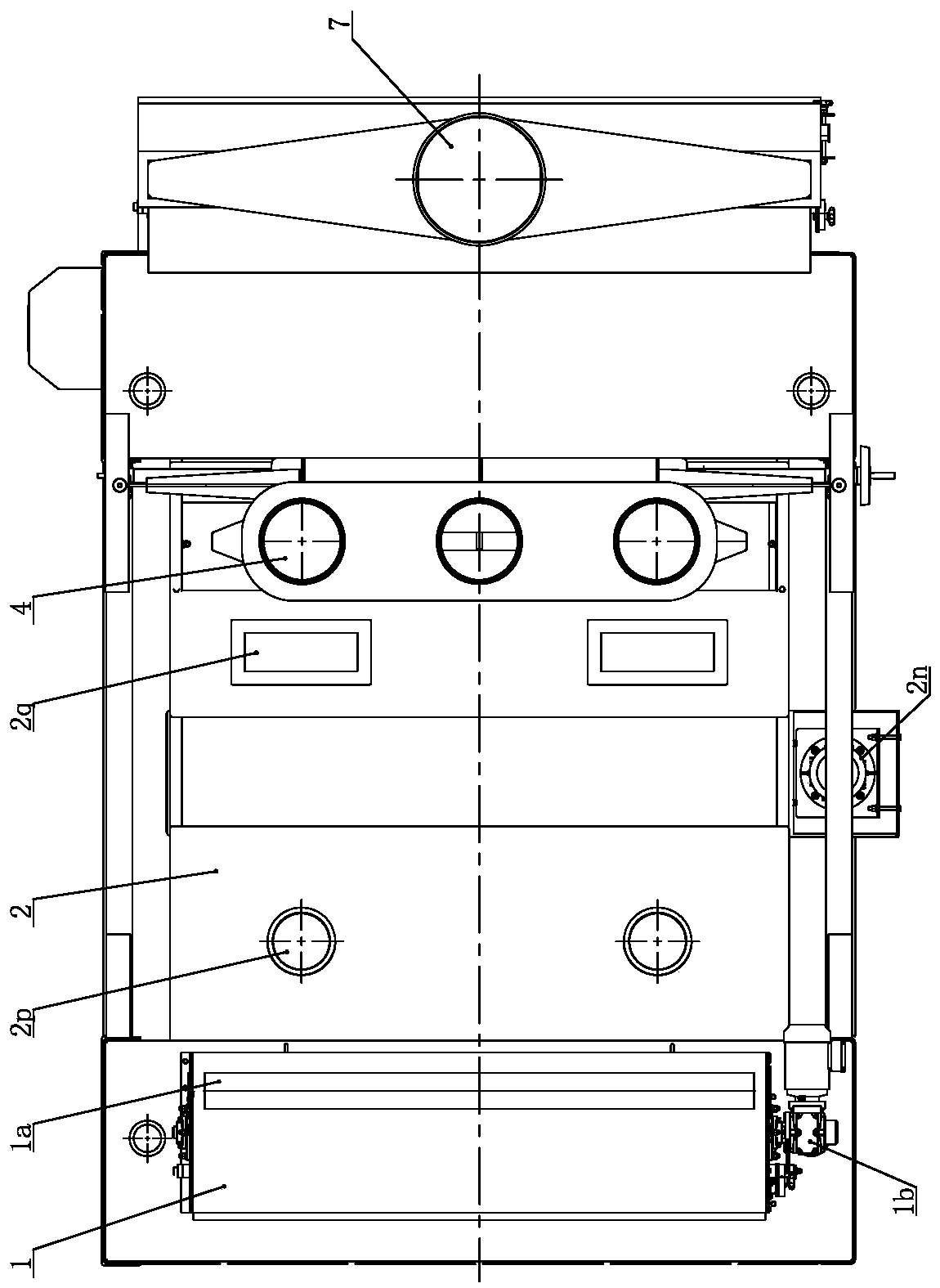

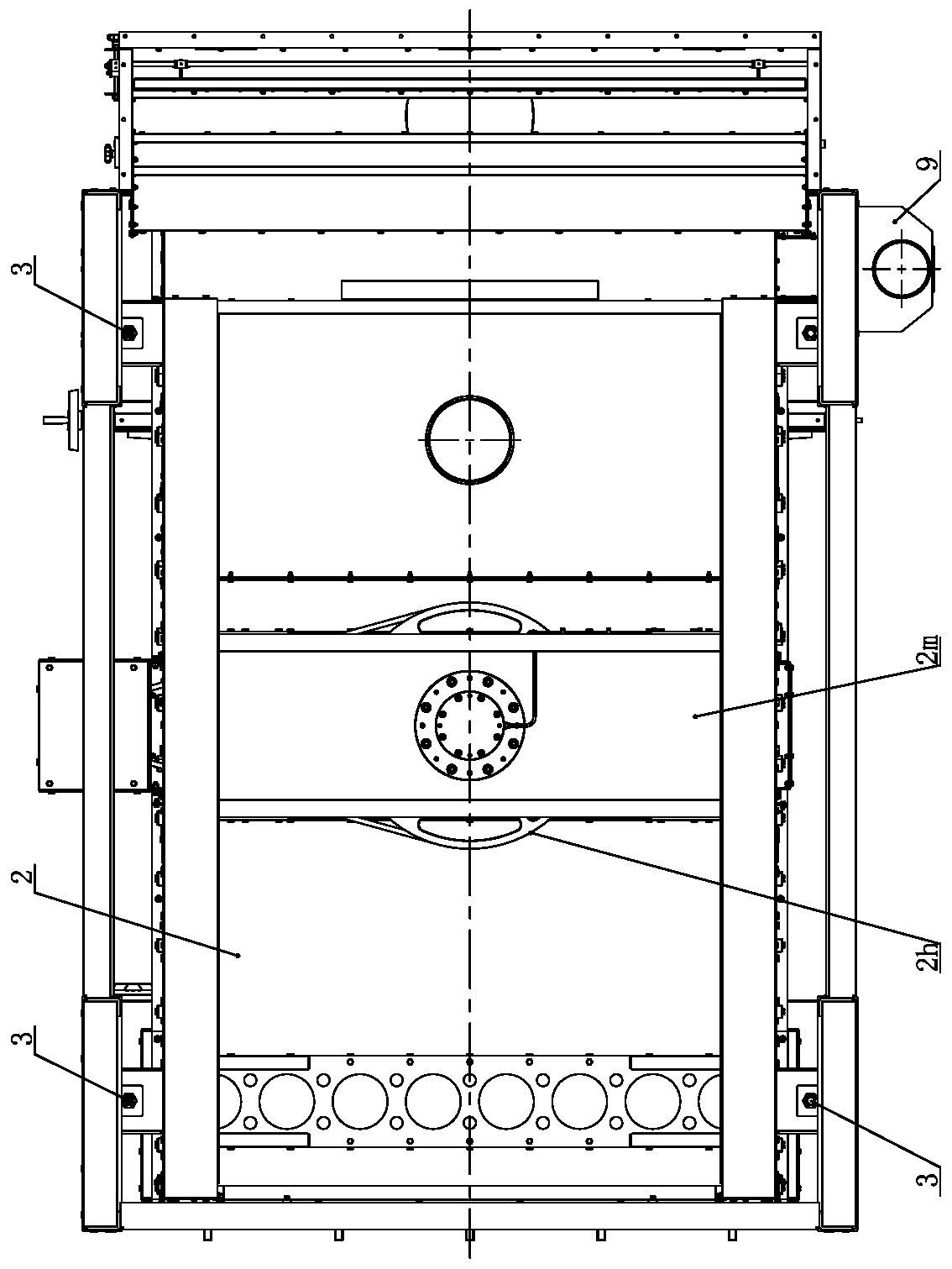

[0041] like figure 1 As shown, the sunflower seed kernel shell separation system of the present invention includes a sheller A and a kernel shell separator B, and the discharge port of the sheller A is fed through the sheller discharge chute and the separator of the kernel shell separator B. The kernel shell separator B is provided with the whole seed outlet, the fine powder outlet, the kernel outlet, the top suction outlet and the tail suction outlet. The top feed port of the air separator C is connected, the bottom of the multi-stage air separator C is provided with an air outlet material outlet, the top right side of the multi-stage air separator C is provided with an air outlet shell port, and the top suction outlet, The air suction outlet at the tail and the air outlet of the air outlet are respectively connected with the air suction pipe 21 .

[0042]After shelling machine A peels the sunflower seeds, the kernels and shells enter the kernel shell separator B for screeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com