Contact line cleaning and oiling device and working method thereof

An oiling device and technology for contact wires, applied in cleaning methods and tools, cleaning methods using tools, devices for coating liquids on surfaces, etc., can solve the problem of unsuitable contact wires with grooves, cleaning methods and complex structures and other problems, to achieve the effect of compact structure, convenient installation, and prevention of oxidation and blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

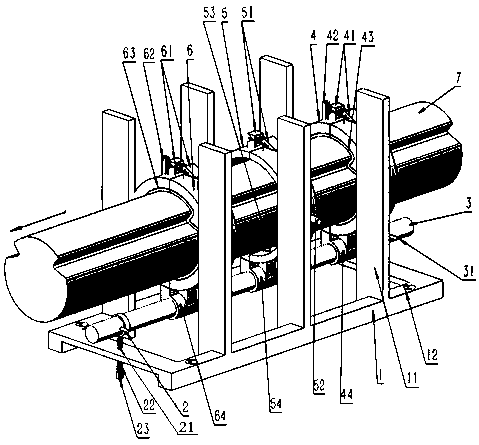

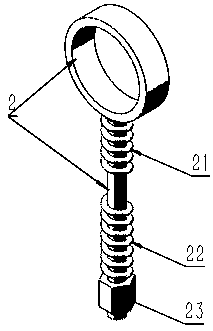

[0054] like figure 1 As shown, a contact line cleaning and oiling device includes a base 1, and the base 1 is provided with a baffle 11 and a support frame 2;

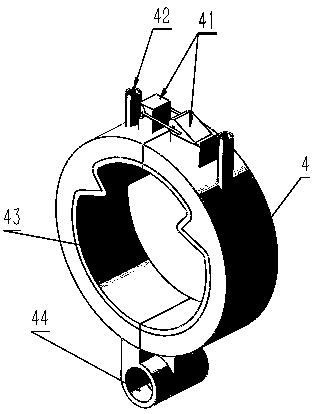

[0055] The support frame 2 is equipped with a shaft rod 3, and the shaft rod 3 passes through the shaft holes of the cleaning clip 4, the air jet clip 5 and the oiling clip 6 in turn and connects and installs the three;

[0056] Limit pins 31 are installed at both ends of the shaft rod 3 .

[0057] In this embodiment, the limiting pins 31 are installed at both ends of the shaft to prevent the shaft from slipping off the support frame.

[0058] The contact line 7 passes through the cleaning clip 4, the air spray clip 5 and the oiling clip 6 in sequence according to the incoming direction;

[0059] The baffles 11 are installed on the outlet ends of the cleaning clip 4 , the air spray clip 5 and the oilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com