Assembly welding method for water-pumping and energy-storage socket ring

A technology of pumped storage and welding methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of welding deformation, poor welding quality, large amount of repair, etc., achieve controllable assembly size and improve product quality. Quality and the effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for assembling and welding a pumped storage seat ring, comprising the following steps:

[0019] 1) In order to meet the transportation requirements, the pumped storage seat ring is divided into two parts at 180° for assembly and welding;

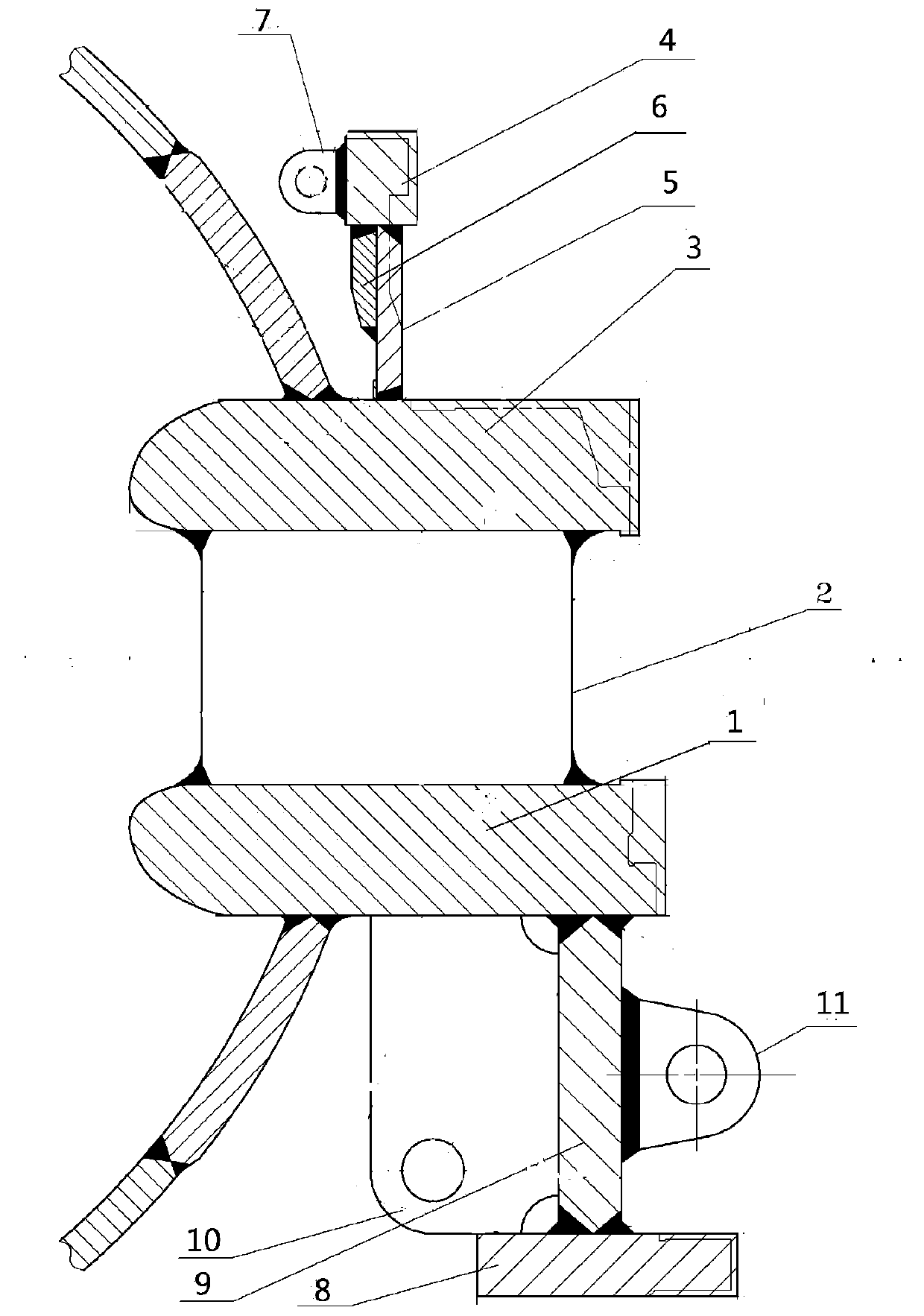

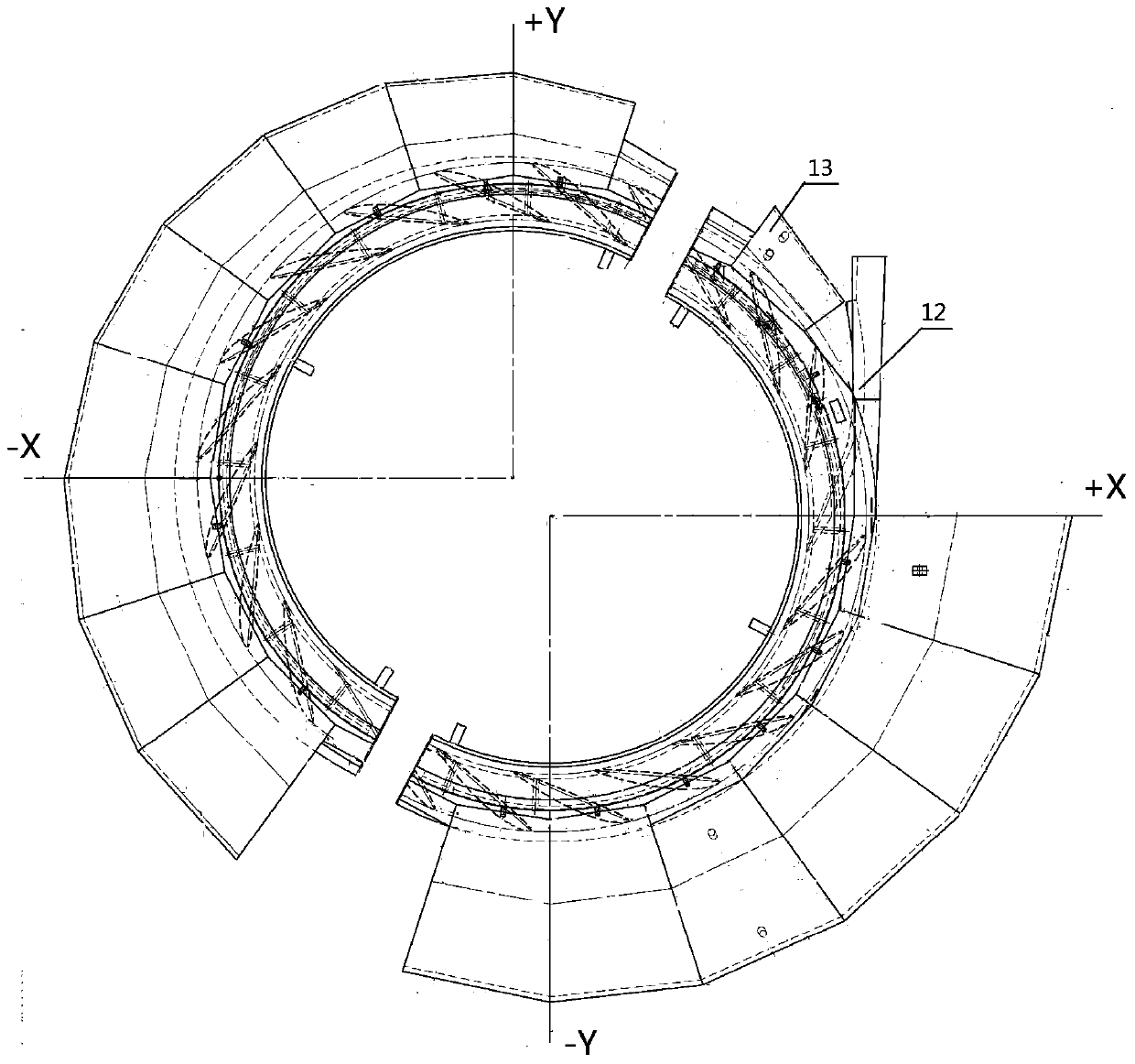

[0020] 2) Assemble the ring plate and the guide vane (such as figure 1 ): Hang the lower ring plate 1 on the platform and adjust the flatness to be no more than 1mm. The outer circle of the lower ring plate 1 is used as the reference, and the center of the circle is determined by combining the inner circle and the processing amount of the joint surface; draw the X, Y axis and the positioning line of the fixed guide vane 2 , and make a sample stamping mark, assemble the fixed guide vane 2 according to the positioning line to ensure that the verticality is not greater than 1mm; hoist the upper ring plate 3 to ensure that the assembly height of the flow surface is +8 ~ +10mm, and the coaxiality is not greater than 1mm; The valv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com