The production process of leather shell frame box type

A production process and frame-enclosing technology, which can be used in box making operations, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc. The effect of high production efficiency, reasonable production line layout, and convenient quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

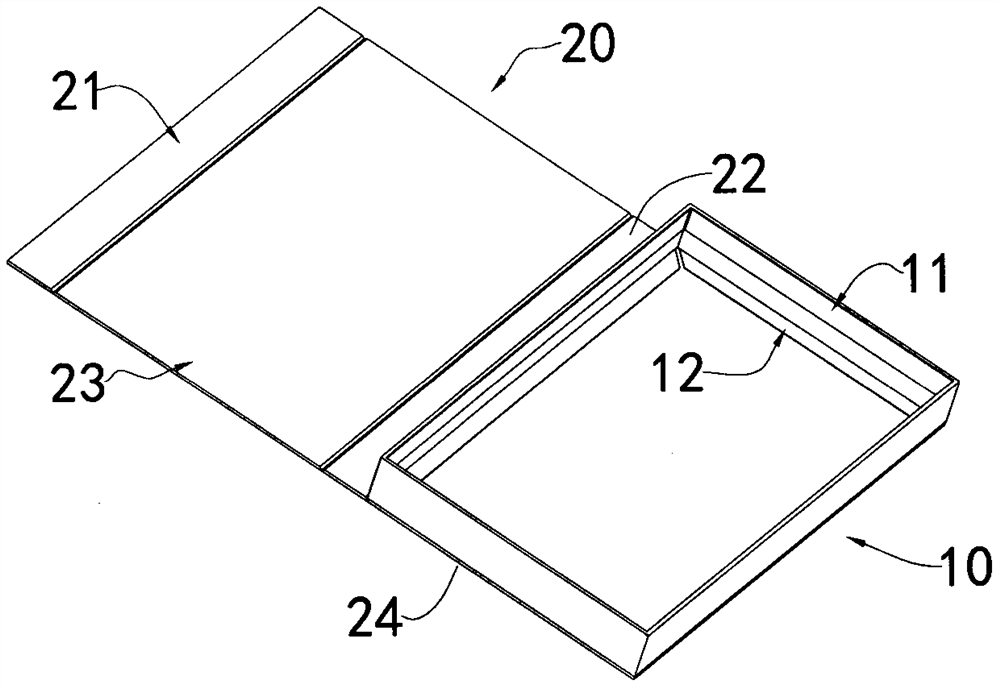

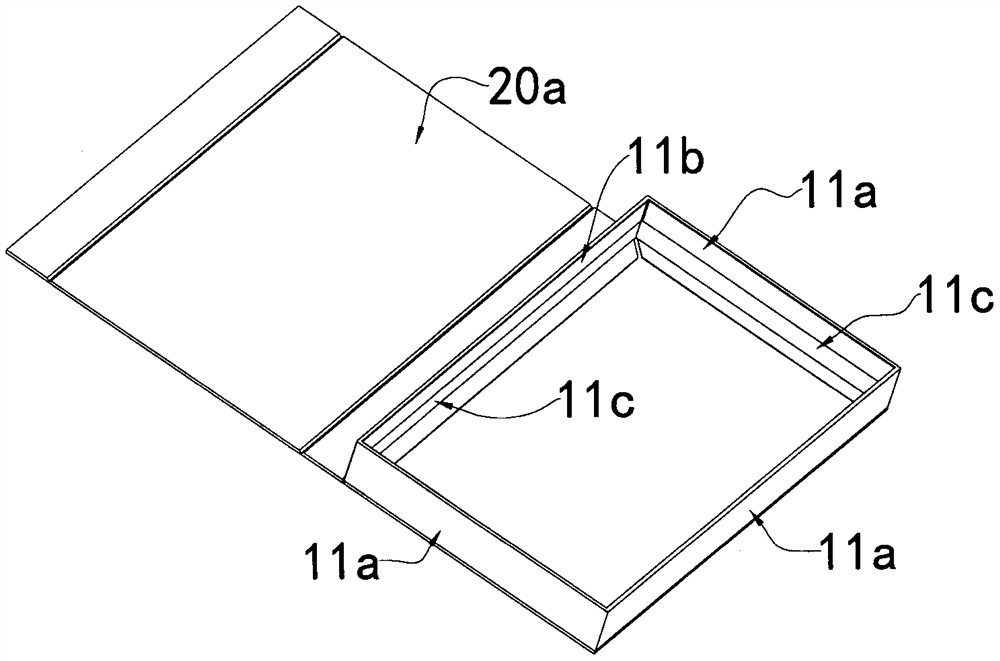

[0065] Take a common box type as an example, such as Figure 1-Figure 4 As shown, the box type is a basic structure of the leather shell and frame box type, mainly including two parts: the surrounding frame 10 and the leather case 20 , and the bottom of the surrounding frame 10 is connected and fixed with the leather case 20 . The leather case 20 includes four surfaces that can be folded, namely a first surface 21, a second surface 22, a third surface 23 and a fourth surface 24, wherein the fourth surface 24 is connected to the surrounding frame 10, and the second surface 22 Aligned and abutted with one side wall of the frame 10, the other side wall of the first surface 21 of the frame 10 is aligned and abutted, and the third surface 23 covers the upper opening of the frame 10; the inner wall of the frame 10 is provided with a decorative The bottom of the face paper 11 is provided with a connecting portion 12, and the connecting portion 12 enables the surrounding frame 10 and ...

Embodiment 2

[0074] The invention also provides a production process of a leather shell frame box type, which is convenient to control the quality of the middle box type and the layout of the production line through standard technical means, so as to improve production efficiency.

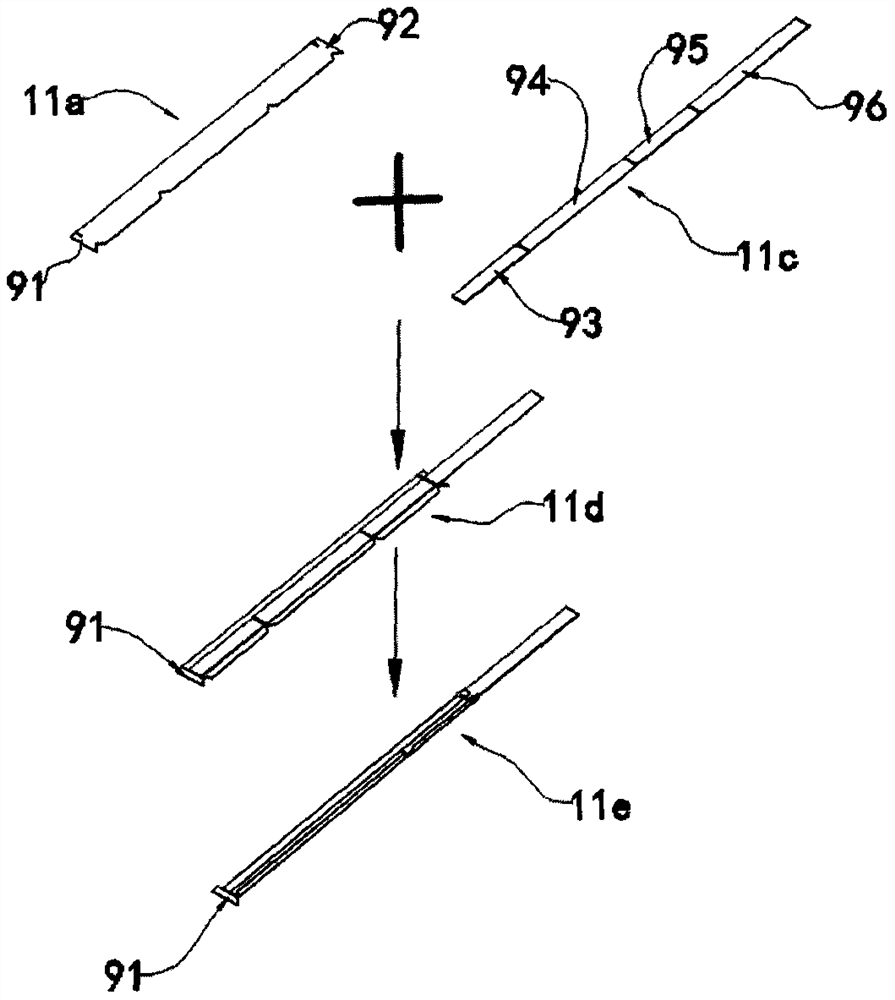

[0075] Such as Figure 5-7 Firstly, the surrounding frame 10 is decomposed into a long face paper incoming material 11a, a short face paper incoming material 11b, and a gray board incoming material 11c, and a first ear portion 91 and a second ear portion 92 are extended on both sides of the long face paper incoming material 11a, The gray board incoming material 11c then goes out folding line by die-cutting and is divided into four sections, is respectively the first section 93, the second section 94, the third section 95 and the fourth section 96, and the first three sections (91 , 92, 93) cut out a small corner at the edge of the corresponding length.

[0076] S1, convey the incoming long tissue paper 11a alo...

Embodiment 3

[0100] Such as Figure 8 , the overall process of this scheme is the same as that of the above-mentioned embodiment, the difference is that a frame production line is added in the X direction, because the process steps of the leather shell are shorter and the production speed is faster, so a frame production line is added in the X direction. The frame production line can match the full-load output of leather shells, which is convenient for increasing product production capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com