Preparation method of backrest carpet part for automobile

A carpet and parts technology, which is applied in the field of preparation of automotive rear carpet parts, can solve problems such as physical harm to operators and environmental pollution of operating space, and achieve the effects of improving production rhythm, improving environmental quality and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

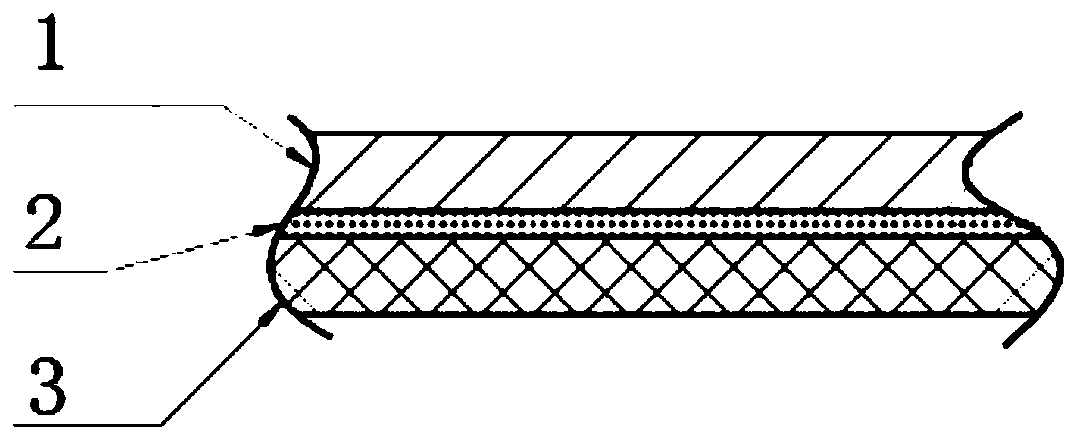

[0031] A kind of preparation method of automobile backrest carpet part, wherein the layered structure of carpet part is as figure 1 As shown, it includes a fleece fabric layer 1, an adhesive layer 2 and a base felt 3 arranged in sequence from top to bottom, wherein the surface density of the fleece fabric layer 1 is 300g / m 2 ;The areal density of the adhesive layer is 70g / m 2 , the areal density of the base felt 3 is 500 g / m 2 The fleece fabric layer 1 comprises 50 parts of 11dtex and 50 parts of 11dtex of PET fibers of different finenesses in the following parts by weight; the raw material of the adhesive layer 2 is LDPE; the raw material of the fleece fabric layer 1 is modulated from PET fibers of different colors , can meet the needs of carpet color, and the raw material of the base layer is PET fiber of a single color.

[0032] The specific production method includes the following steps:

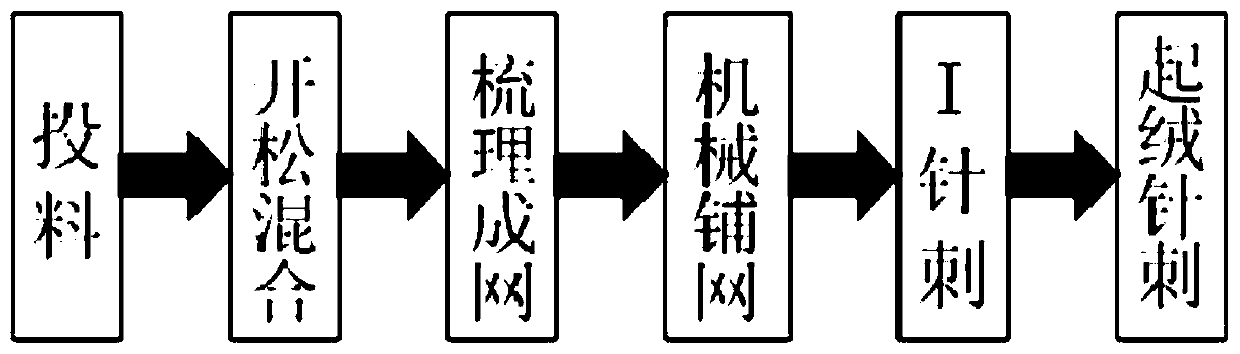

[0033] (1) The preparation of fleece fabric layer 1, such as figure 2 As shown,...

Embodiment 2

[0040] A kind of preparation method of automobile backrest carpet part, wherein the layered structure of carpet part is as figure 1 As shown, it includes a fleece fabric layer 1, an adhesive layer 2 and a base felt 3 arranged in sequence from top to bottom, wherein the surface density of the fleece fabric layer 1 is 270g / m 2 ;The areal density of the adhesive layer is 63g / m 2 , the areal density of the base felt 3 is 450 g / m 2 The fleece fabric layer 1 includes 40 parts of 11dtex and 60 parts of 11dtex of PET fibers of different finenesses in the following parts by weight; the raw material of the bonding layer 2 is LDPE; the raw material of the fleece fabric layer 1 is modulated from PET fibers of different colors , can meet the needs of carpet color, and the raw material of the base layer is PET fiber of a single color.

[0041] The specific production method includes the following steps:

[0042] (1) The preparation of fleece fabric layer 1, such as figure 2 As shown, t...

Embodiment 3

[0048] A kind of preparation method of automobile backrest carpet part, wherein the layered structure of carpet part is as figure 1 As shown, it includes a fleece fabric layer 1, an adhesive layer 2 and a base felt 3 arranged in sequence from top to bottom, wherein the surface density of the fleece fabric layer 1 is 330g / m 2 ;The areal density of the adhesive layer is 77g / m 2 , the areal density of the base felt 3 is 550 g / m 2 The fleece fabric layer 1 comprises 60 parts of 11dtex and 40 parts of 11dtex of PET fibers of different finenesses in the following parts by weight; the raw material of the adhesive layer 2 is LDPE; the raw material of the fleece fabric layer 1 is modulated from PET fibers of different colors , can meet the needs of carpet color, and the raw material of the base layer is PET fiber of a single color.

[0049] The specific production method includes the following steps:

[0050] (1) The preparation of fleece fabric layer 1, such as figure 2 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com