A New Type of Hybrid Transmission

A hybrid power and transmission technology, applied in the field of new hybrid power transmission, can solve the problems of complex structure, low efficiency and low reliability of the transmission, and achieve the effects of low development difficulty, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

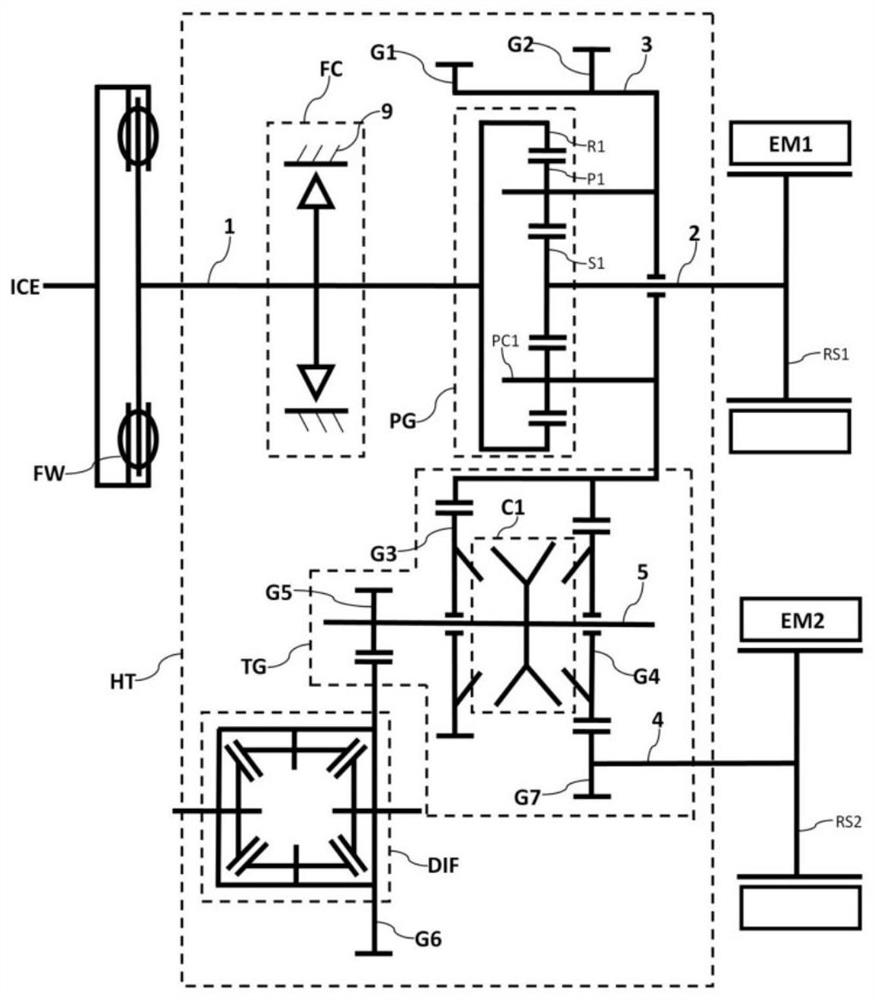

[0065] Example 1, see figure 1 , figure 1 The first embodiment of the power-split hybrid transmission provided by the present invention includes a single planetary gear mechanism PG, a differential gear DIF, a transmission mechanism TG, a housing 9, a first transmission shaft 1, and a second transmission shaft 2 , the third transmission shaft 3 , the fourth transmission shaft 4 and the fifth transmission shaft 5 .

[0066] The power source of the new hybrid transmission HT includes an engine ICE, a first electric machine EM1, and a second electric machine EM2, the first electric machine EM1 includes a first rotor shaft RS1, and the first electric machine EM1 passes through the first rotor shaft RS1 To input or output power, the second electric machine EM2 includes a second rotor shaft RS2, and the second electric machine EM2 inputs or outputs power through the second rotor shaft RS2.

[0067] The single planetary mechanism PG includes a first sun gear S1, a first ring gear R...

Embodiment 2

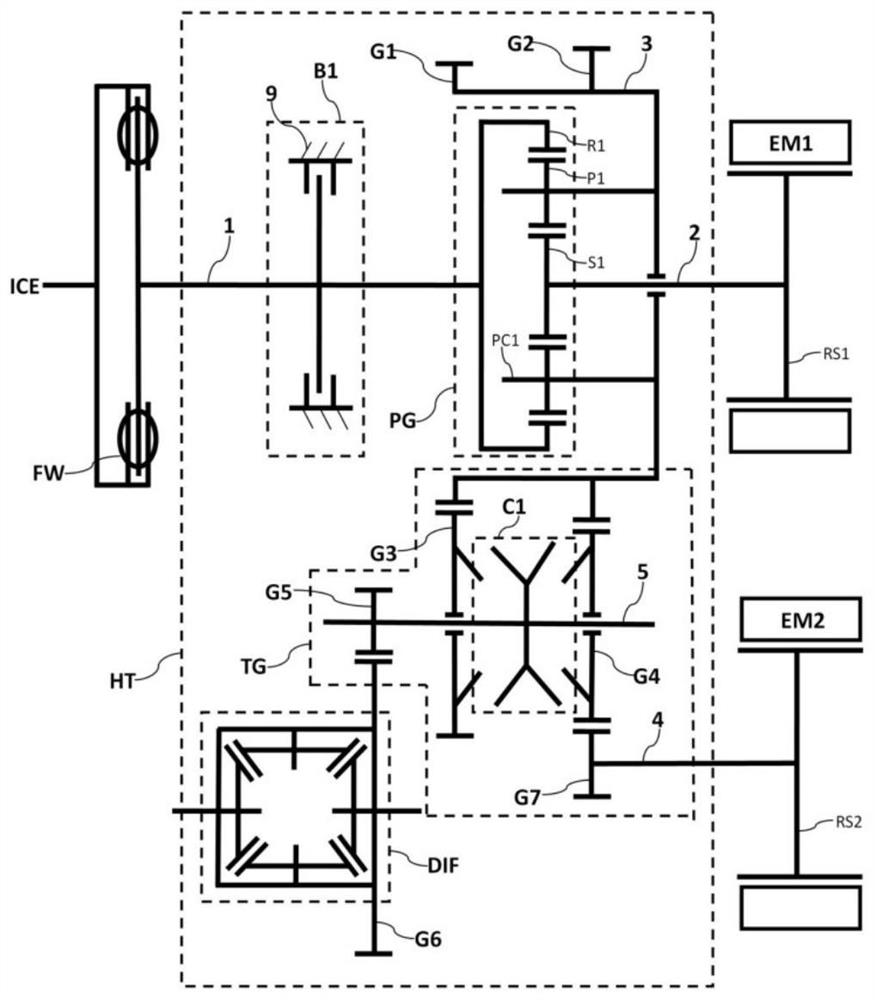

[0100] Example 2, such as figure 2 as shown, figure 2 Embodiment 2, which is the second embodiment of the power-split hybrid transmission provided by the present invention, is similar to Embodiment 1, except that the brake B1 is used in Embodiment 2 to replace the one-way clutch FC in Embodiment 1. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com