Framework apparatus based on novel damping structure

A vibration damping structure, a new type of technology, applied in the direction of the transmission device driven by the electric motor, the device for the lateral relative movement between the chassis and the bogie, the bogie, etc., can solve the problem of increasing the risk of damage to the axle box, mechanical design and layout Difficulty, improvement and other issues, to achieve the effect of improving the conversion efficiency and control efficiency of electric energy utilization, enhancing energy saving and environmental protection attributes, and simplifying the control program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

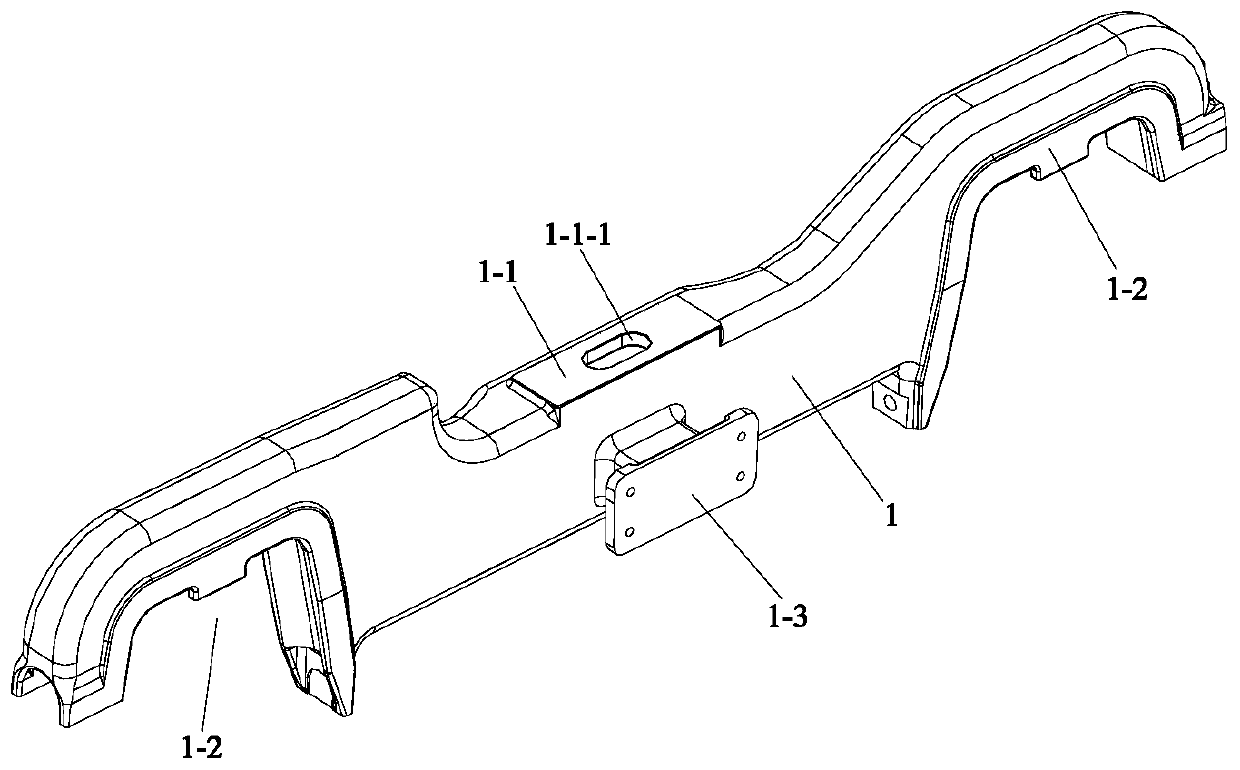

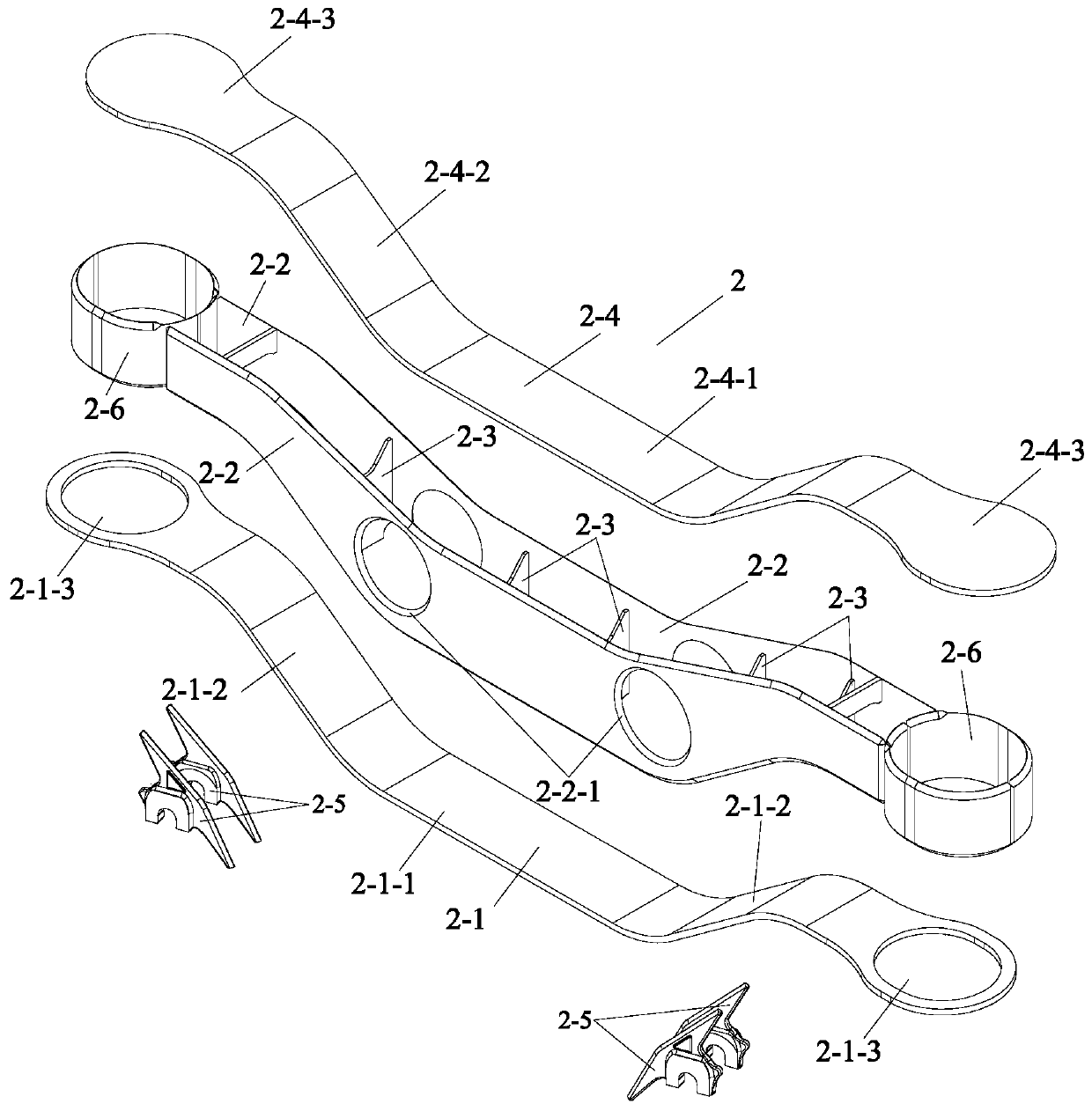

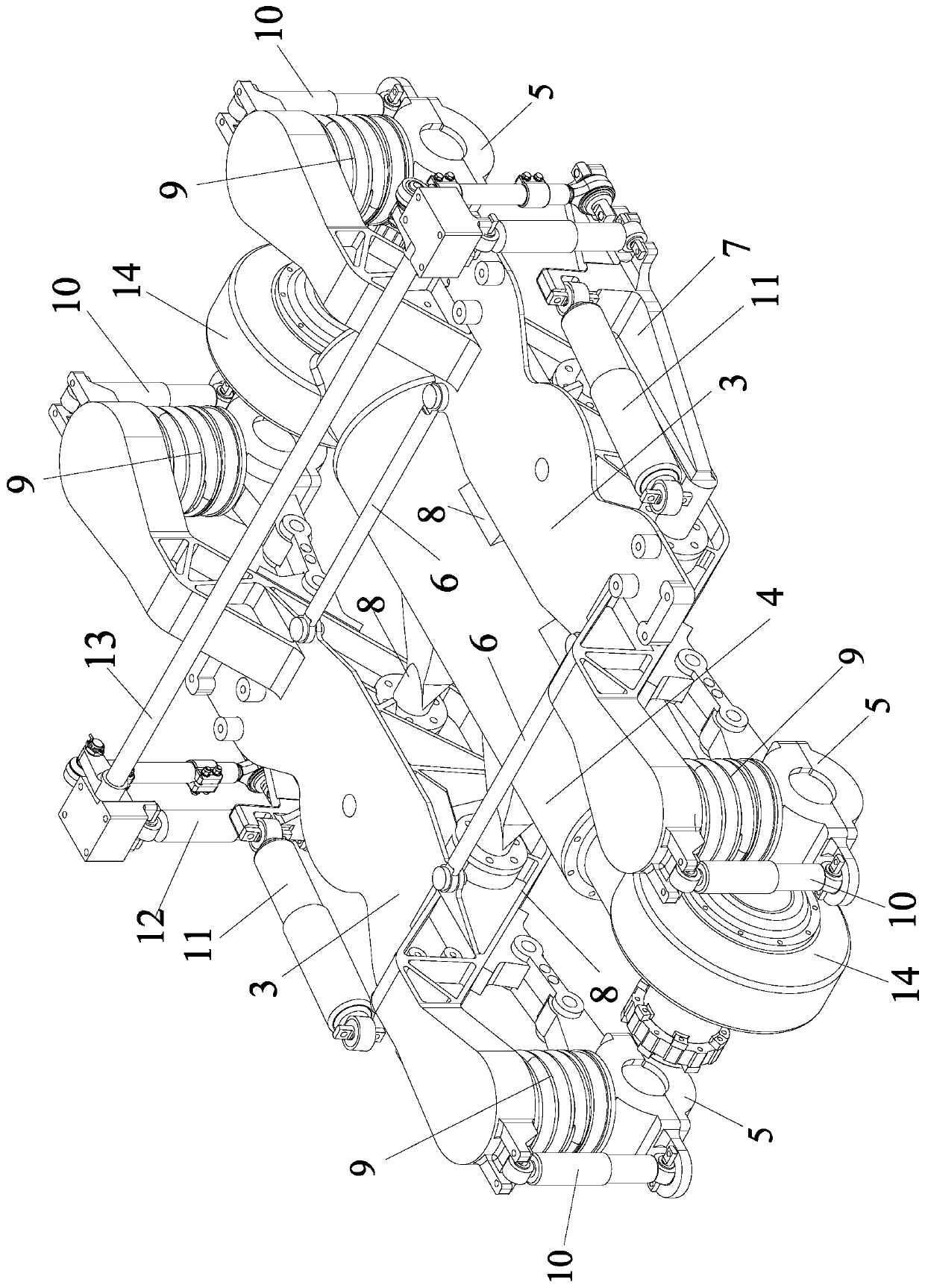

[0051] like Figure 3 to Figure 12 As shown, the frame device based on the new damping structure of the present invention includes a bidirectional output shaft motor, two gear boxes 14, four primary steel springs 9, four primary vertical shock absorbers 10, and two forged side beams 3. Longitudinal motor casing 4. Four built-in primary suspension axlebox devices for four wheelsets 5. Two side beam balance links 6. Two combined connecting seats 7. Two anti-snake shock absorbers 11. Two The secondary vertical shock absorber 12, the door-shaped anti-rolling torsion bar mechanism 13 and the four casing side beam connecting columns 8; the bidirectional output shaft motor is coaxially fixed in the vertical motor casing 4, and the two gears The box 14 is rotationally symmetrically arranged at both ends of the vertically mounted motor casing 4; the front and rear ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com