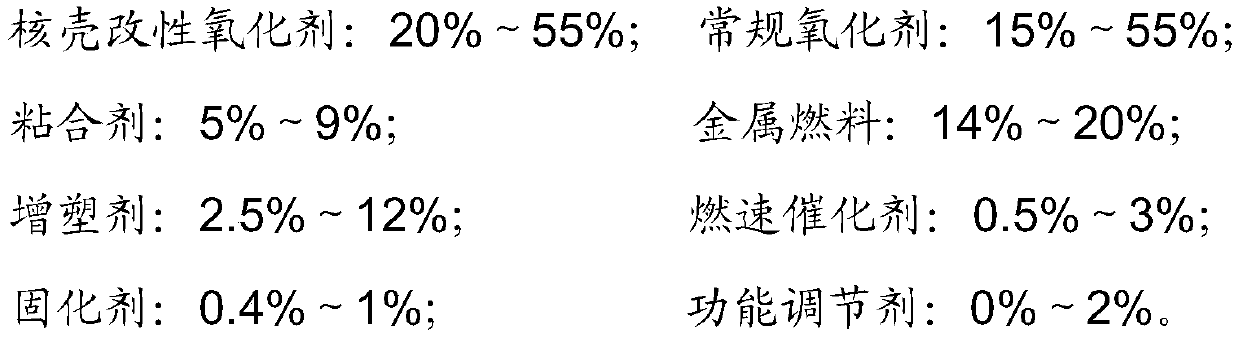

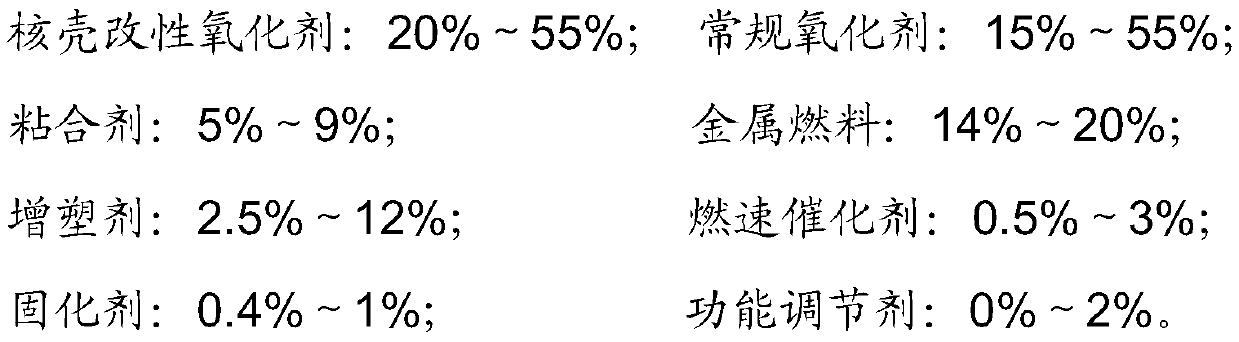

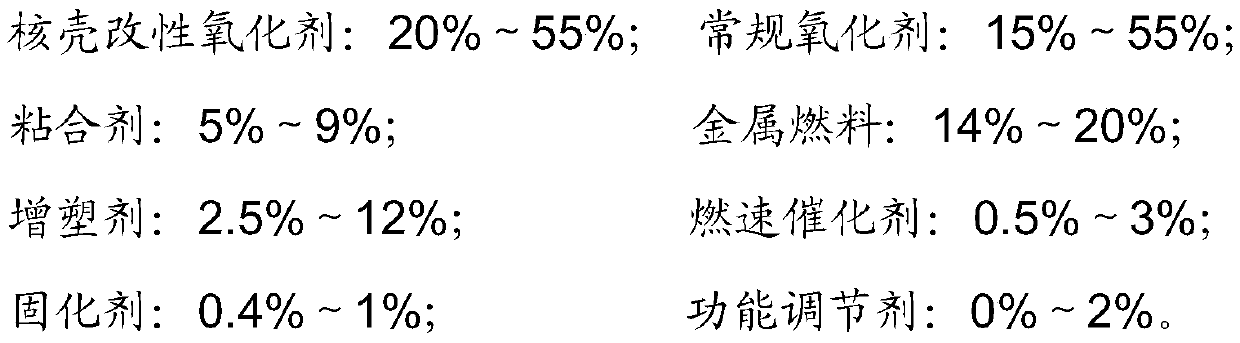

Solid propellant containing core-shell modified oxidant and preparation method of solid propellant

A solid propellant and oxidant technology, which is used in offensive equipment, explosives processing equipment, and compressed gas generation to achieve the effects of high thermal conductivity, optimized stacking state, and improved process performance and safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of described core-shell modified oxidant comprises the following steps:

[0041] 1) Add deionized water to potassium perchlorate, stir fully under heating conditions for 1 to 3 hours, then add dispersant and reducing agent in turn, and stir to form a potassium perchlorate suspension;

[0042] 2) Under stirring conditions, add ammonia water dropwise to the silver nitrate aqueous solution until the precipitate that is produced at the beginning just dissolves to obtain a solution;

[0043] 3) under stirring condition, the solution that step (2) is obtained is added dropwise in the potassium perchlorate suspension of step (1), and continues to stir until unreacted silver ion is not detected in the solution;

[0044] 4) filtering out the solid components in the solution in step (3), repeatedly washing with an organic solvent, and drying to obtain the finished product of the modified oxidant.

[0045] The amount of deionized water added in step (1) is ...

Embodiment 1

[0073] A solid propellant comprising a core-shell modified oxidant, the main composition of which (by mass percentage) is as follows: core-shell modified oxidant KP, 32%; conventional oxidizer AP, 36%; binder HTPB, 6.8%; Metal fuel Al, 18%; burning rate catalyst GFP, 2.5%; plasticizer DOS, 4%; curing agent TDI, 0.5%; function regulator is graphene, 0.2%.

[0074] A solid propellant comprising a core-shell modified oxidizer, the preparation method of which is as follows:

[0075] (1) Using potassium perchlorate with a size of about 300 μm, after surface silverization treatment, a core-shell modified oxidant KP with a silver metal core-shell thickness of about 1 μm is obtained, and the particle size D is selected by sieving 50 About 300μm products;

[0076] (2) According to the formula ratio, the formula raw materials are weighed respectively;

[0077] (3) First add HTPB, GFP, and DOS components into the premix container in sequence, and stir evenly by hand; then add graphene,...

Embodiment 2

[0083] A solid propellant comprising a core-shell modified oxidant, the formula of which is mainly composed (calculated by mass percentage) is as follows: core-shell modified oxidant KP, 51%; conventional oxidant AP, 17%; binder HTPB, 6.8%; Metal fuel Al, 18%; burning rate catalyst GFP, 2.5%; plasticizer DOS, 4%; curing agent TDI, 0.5%; function regulator is graphene, 0.2%.

[0084] A solid propellant comprising a core-shell modified oxidizer, the preparation method of which is as follows:

[0085] (1) Using potassium perchlorate with a size of about 300 μm, after surface silverization treatment, a core-shell modified oxidant KP with a silver metal core-shell thickness of about 1 μm is obtained, and the particle size D is selected by sieving 50 About 300μm products;

[0086] (2) According to the formula ratio, the formula raw materials are weighed respectively;

[0087] (3) First add the weighed HTPB, GFP, and DOS components into the premix container in turn, and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com