Method for separating slag from powder in primary treatment and secondary treatment processes of stainless steel slag

A technology of stainless steel slag and secondary treatment, which is applied in the treatment of stainless steel slag, the primary treatment of stainless steel slag, and the separation of slag powder in the secondary treatment process, which can solve the problems of insufficient mobility, increased energy consumption, large equipment, etc., and achieve protection Effects on personal health, improved dust collection efficiency, and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

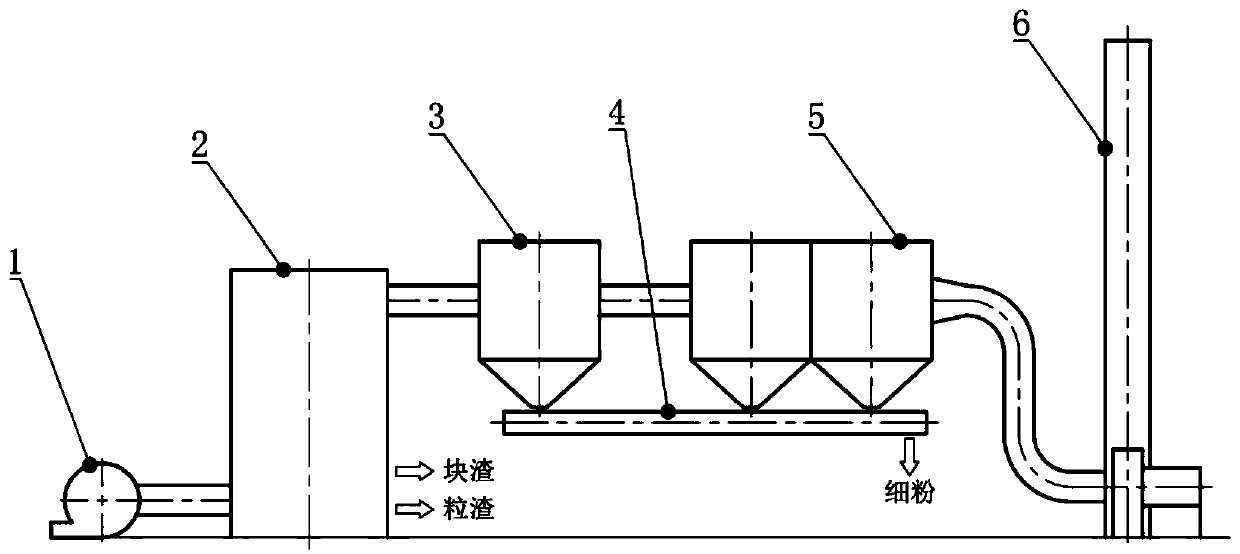

[0038] Specific examples of the present invention are attached Figure 1-3 A device for separating slag powder during primary treatment and secondary treatment of stainless steel slag shown includes: air supply device 1, slag turning mechanism 2, fine powder settling chamber 3, fine powder conveying device 4, fine powder dust collection chamber 5, Clean air exhaust device 6;

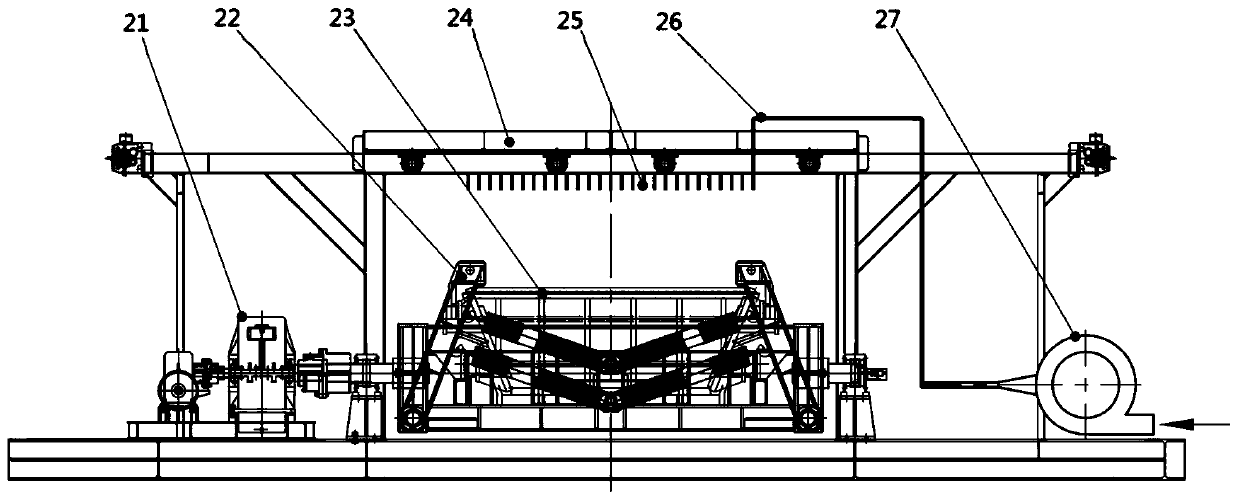

[0039] The air supply device 1 includes a pulse air pump, a metal pulse tube, and an air spray head 25 .

[0040] The air nozzles are distributed in a fan shape in the horizontal direction on the movable sealing cover 24 opposite to the mechanical movement of the slag turning machine. The gas passes through the pulse type air pump 27 to generate a certain pressure (such as 0.01-2MPa) and then press the set frequency (8 times per minute). -20 times) to realize intermittent impact on the slag body inside the slag turning mechanism 2 .

[0041] The slag dumping mechanism 2 includes a shell, a slag pan 23 , ...

specific Embodiment 2

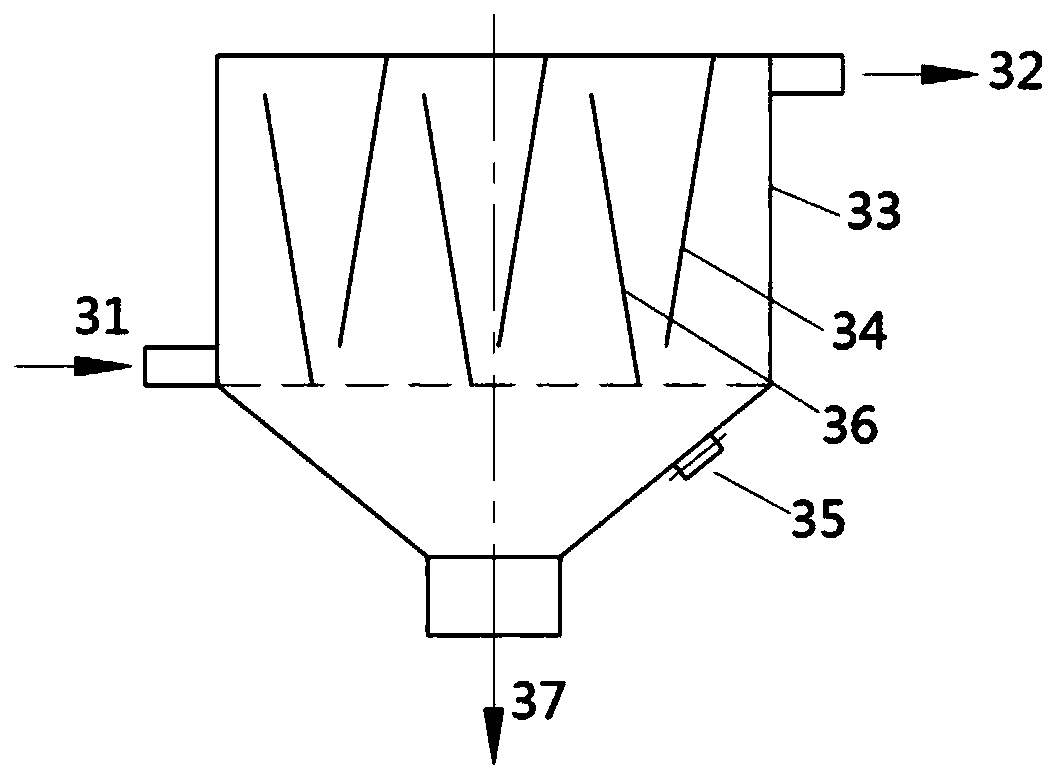

[0057] The difference between specific embodiment 2 and specific embodiment 1 is that: the fine powder settling chamber in specific embodiment 2 adopts the cyclone separation chamber to carry out the primary separation of fine powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com