Internal filter element of precious metal recoverer

A precious metal recovery and filter element technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, gas treatment, etc., can solve the problem of platinum fine particle loss and other problems, and achieve the effect of improving product quality, ensuring cleanliness, and reducing platinum consumption

Inactive Publication Date: 2020-04-10

永兴县永和贵金属有限责任公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the main methods to reduce platinum consumption are to install palladium capture nets, use DEC functional nets, or install precious metal recyclers. Among them, the addition of capture nets or the use of functional nets has obvious effects on reducing platinum consumption, but there are still considerable A large number of fine platinum particles are lost along with the high-temperature gas along the process pipeline. Under normal operating conditions, the average platinum consumption value of the platinum mesh: 0.040-0.042 g / ton

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

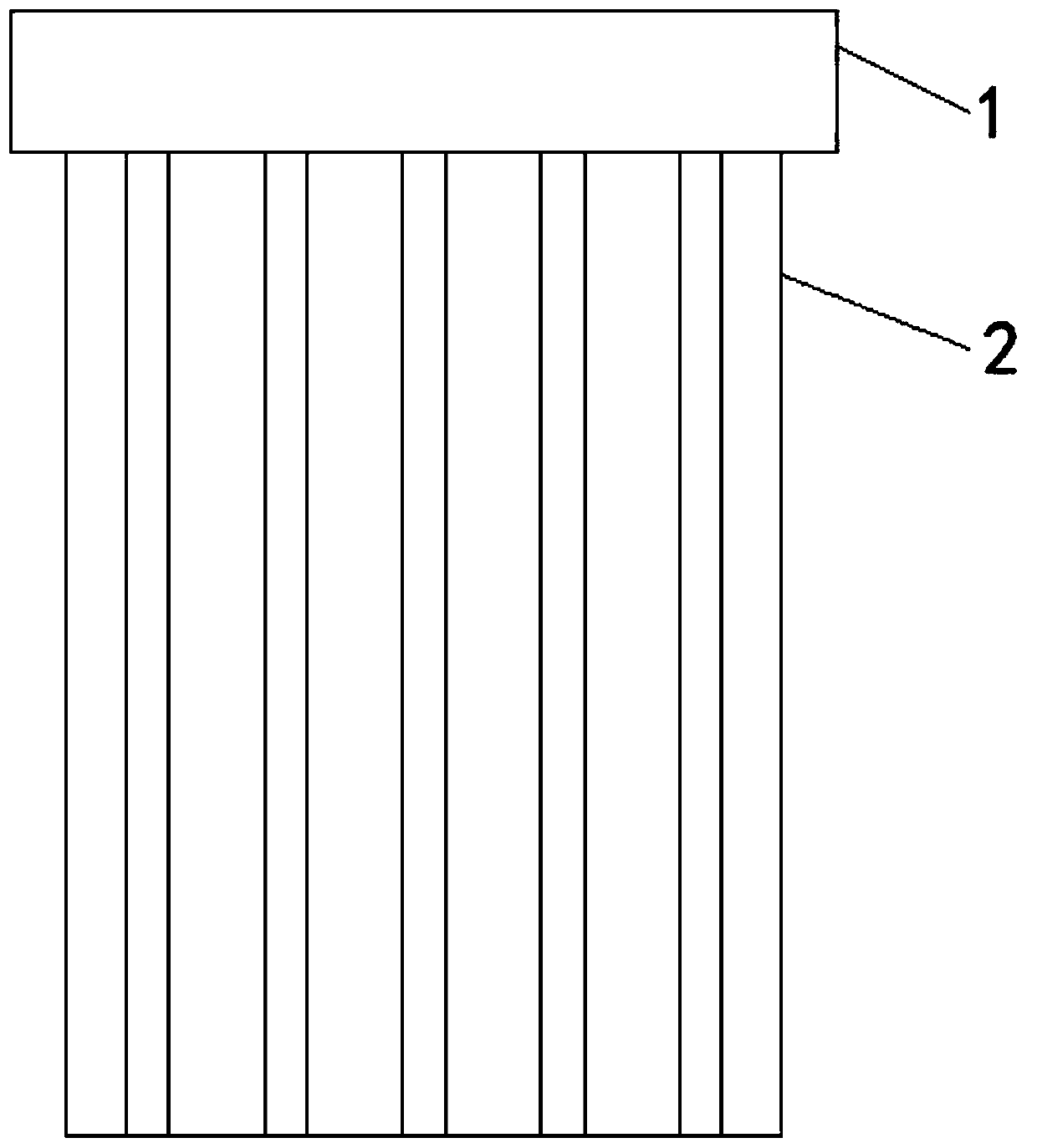

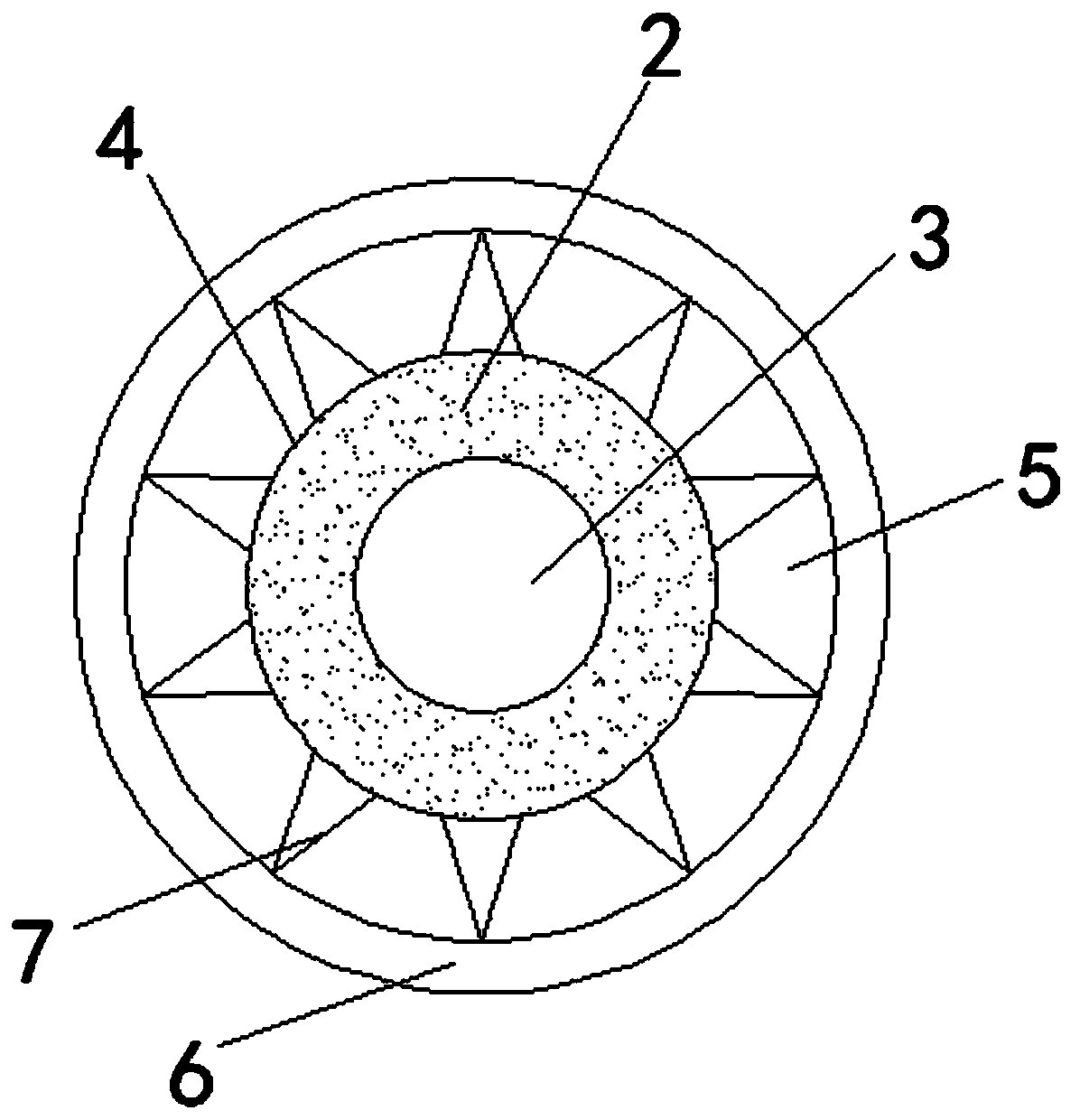

The invention relates to the technical field of comprehensive recovery, and discloses an internal filter element of a precious metal recoverer. The internal filter element comprises an end cap, a supporting framework is fixedly mounted at the bottom end of the end cover; a reinforcing framework is fixedly installed on the inner wall of the supporting framework, the outer wall of the supporting framework is sleeved with a filtering layer, the inner wall of the filtering layer is fixedly provided with a folding framework, the outer wall of the filtering layer is sleeved with a sealing piece, theinner wall of the filtering layer is fixedly provided with a supporting layer, the supporting layer is a stainless steel net, and the wire diameter of the stainless steel net in the supporting layeris large. The internal filter element is mounted in the precious metal recoverer to filter impurities, powders and precious metal micro-particles in nitrogen oxide gas effectively, so that the cleanliness of process gas is guaranteed, surge caused by scaling of nitrogen oxide compressor blades is avoided, and the product quality is effectively improved; and besides, platinum, palladium and other precious metals in the gas are efficiently recycled, and the purpose of effectively reducing platinum consumption in nitric acid production is achieved.

Description

technical field [0001] The invention relates to the technical field of comprehensive recovery, in particular to an internal filter element of a precious metal recovery device. Background technique [0002] The production of nitric acid uses ammonia and oxygen as raw materials, and the two are fully combusted and combined through platinum mesh catalysis. In the production of nitric acid, the working temperature of the platinum mesh is 850°C to 880°C. The loss will also gradually increase with the working time. [0003] At present, the main methods to reduce platinum consumption are to install palladium capture nets, use DEC functional nets or install precious metal recyclers. Among them, the addition of capture nets or the use of functional nets has obvious effects on reducing platinum consumption, but there are still considerable A large number of fine platinum particles are lost along the process pipeline with the high-temperature gas. Under normal operating conditions, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B11/02B01D46/24

CPCB01D46/2411B01D2258/02C22B11/028

Inventor 陈文明刘三平李明曹安平刘林

Owner 永兴县永和贵金属有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com