Electric infiltration phenomenon-based reversible micro-pump

An electrowetting and phenomenon technology, applied in the field of reversible micropumps, can solve the problems of low service life of piezoelectric pumps, single fluid flow direction control, and limited application range, etc., to achieve improved service life, strong reliability, and design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

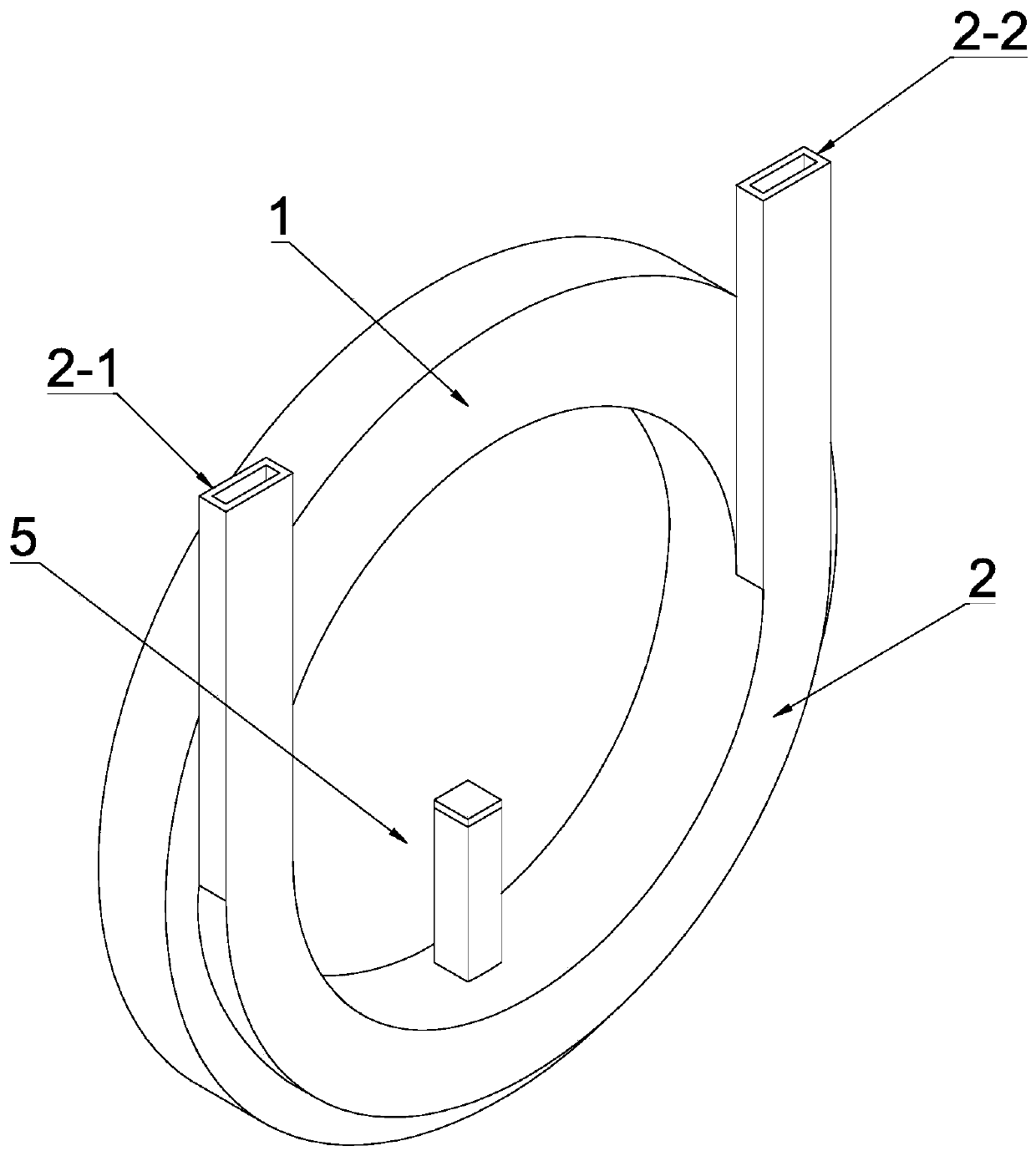

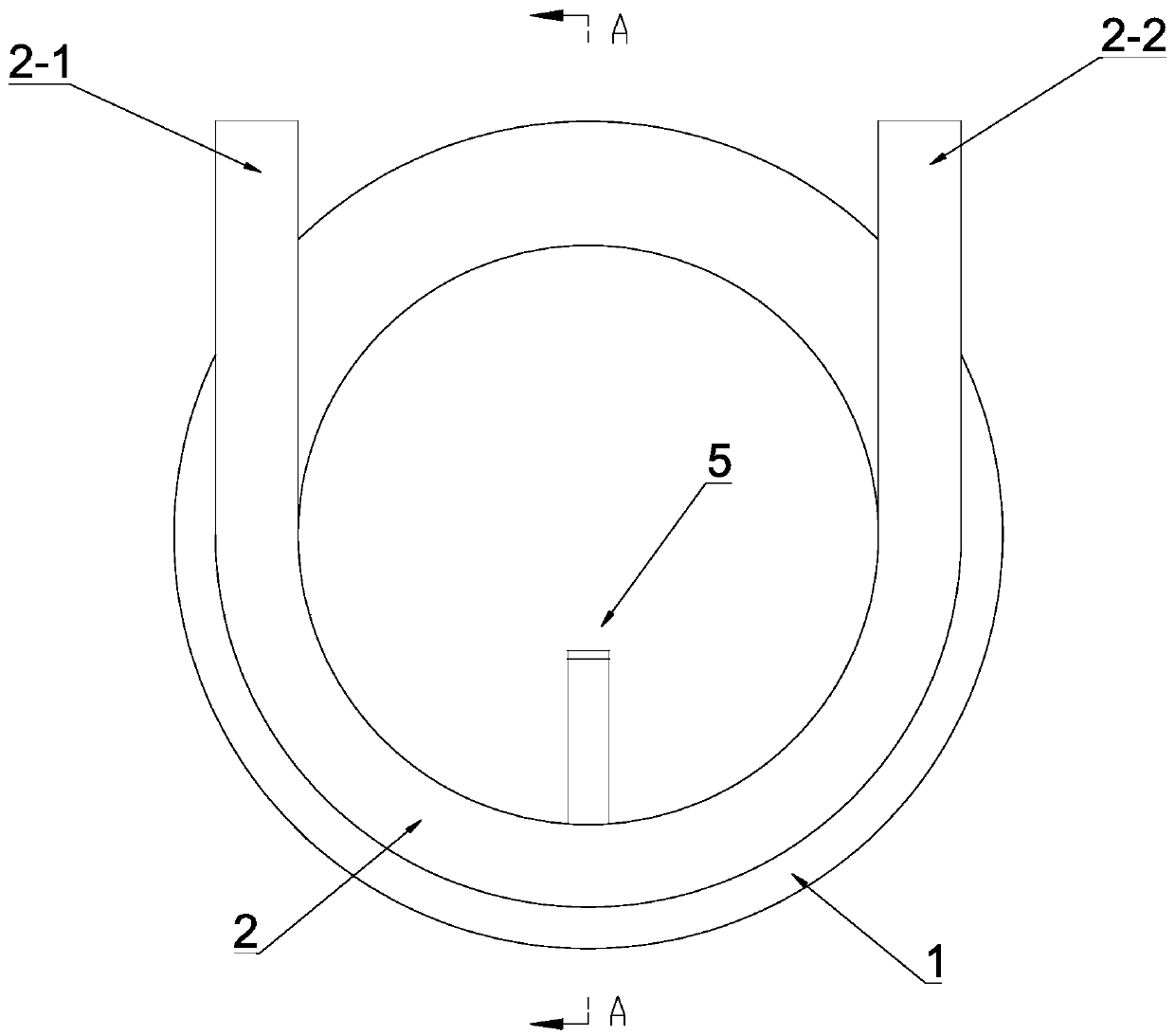

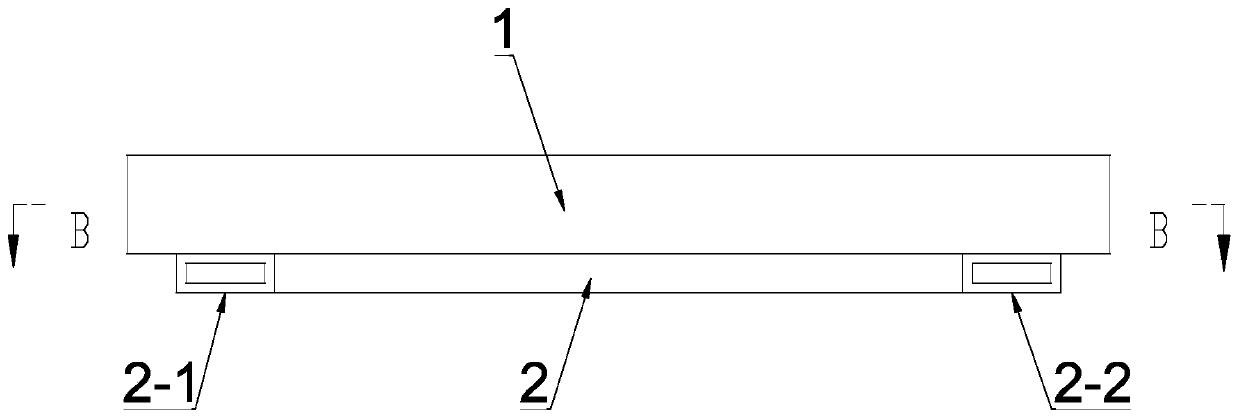

[0033] see Figure 1-Figure 7 , a reversible micropump based on the electrowetting phenomenon, characterized in that it includes an annular pump chamber 1, a liquid passage 2 arranged on the annular pump chamber 1; the annular pump chamber 1 and the liquid passage 2 There is a mesh 3 for connecting the annular pump chamber 1 and the liquid passage 2; the liquid passage 2 includes a first pump port 2-1 and a second Two pump ports 2-2; wherein, the annular pump chamber 1 is provided with a pump to pump the liquid in the annular pump chamber 1 to the first pump port 2-1 or the second pump port 2-2 The electrowetting power mechanism 4; wherein, the electrowetting power mechanism 4 includes the electrowetting liquid arranged in the annular pump chamber 1, nested on the side wall of the annular pump chamber 1 for driving the electrowetting The electrode array ring 4-1 where the liquid moves circularly along the annular pump chamber 1 and the dielectric hydrophobic material ring 4-2...

Embodiment 2

[0048] see Figure 8 , the other structure of this embodiment is the same as that of Embodiment 1, except that: the liquid passage 2 includes a first liquid passage 6 and a second liquid passage 7 respectively arranged at both ends of the annular pump chamber 1; The lower end of a liquid passage 6 communicates with the annular pump chamber 1 through the mesh 3, and the upper end is the first pump port 2-1; the lower end of the second liquid passage 7 communicates with the annular pump chamber through the mesh 3 1 connected, the upper end is the second pump port 2-2. With the above-mentioned structure, by changing the positive and negative poles of the DC power supply between the electrode array ring 4-1, the circular motion direction of the electrowetting liquid in the annular pump chamber 1 can be changed, thereby changing the motion direction of the pumped liquid, and micro Pumping and reversing functions of the pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com