Piezoelectric shunt semi-passive control device and design method for vibration control of propulsion shafting

A technology of vibration control and design method, applied in the direction of propulsion transmission, transmission with synchronous propulsion components, mechanical vibration control, etc., can solve problems such as system complexity, and achieve the effect of reducing demand, small additional mass, and widening bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

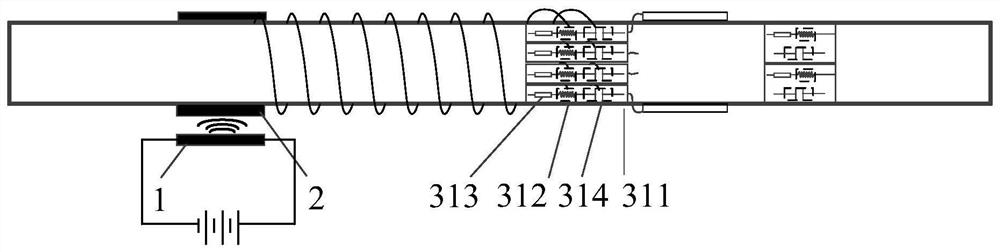

[0067] Such as figure 1 As shown, the power supply device adopts the induction telemetry power supply device.

[0068] The transmitting end (stationary end 1) is composed of a power supply, a power adapter, a power transmitter, and a power cord. The voltage of the transmitter is 40V DC (that is, the output voltage of the receiving end of the induction telemetry power supply). It can be supplied by batteries, or by inductive or mains power. Usually it can be obtained by inputting 220V AC power to the power adapter. The installation position of the power transmitter from the outer edge of the shaft system is related to the current size: 1000mA current distance is 5-10mm; 500mA current distance is 10-15mm; 250mA current distance is 15-20mm. The coil wound on the shaft is located in the middle of the front surface of the power transmitter probe.

[0069] The receiving end 2 is composed of a coil wound on the rotating shaft. After selecting a suitable installation position on ...

Embodiment 2

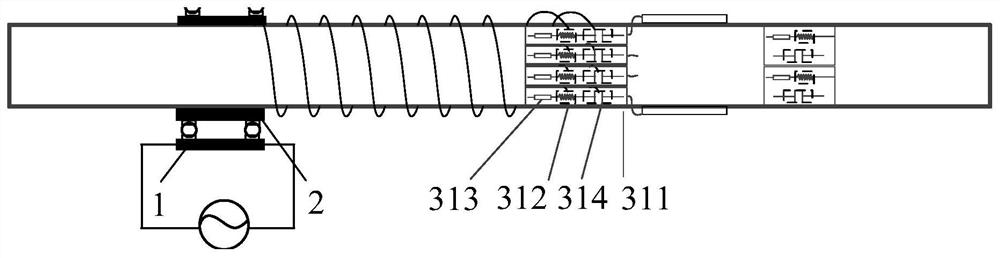

[0108] On the basis of the first embodiment, the power supply device is changed to a slip ring power supply device.

[0109] The stator (transmitter 1) of the slip ring power supply device is composed of an annular shell, a terminal, a conductive ring, a brush, and a shell fixing device. The rotor (receiving end 2) of the slip ring power supply device is composed of conductive rings and brushes; the rotor of the slip ring power supply device is fixed on the propulsion shafting through interference fit, and the stator of the slip ring power supply device is supported by precision bearings. The power supply unit can input voltage up to 500V.

[0110] The piezoelectric shunt circuit is fixed to the shaft and rotates with the shaft. First wrap the piezoelectric shunt circuit that rotates with the shaft on the shaft for 2 to 3 layers with adhesive tape to achieve a fixed effect, and finally use a hose clamp or hose clamp to hoop the piezoelectric shunt circuit and fix it on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com