Reducer gasket, reducer and method for determining thickness of reducer gasket

A reducer and gasket technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems affecting the life of bearings and the performance of the whole machine, inconsistent bearing assembly height, and the same preload, etc., to achieve Solve the inclination problem of the main bearing system, ensure the thickness of the gasket is consistent, and improve the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

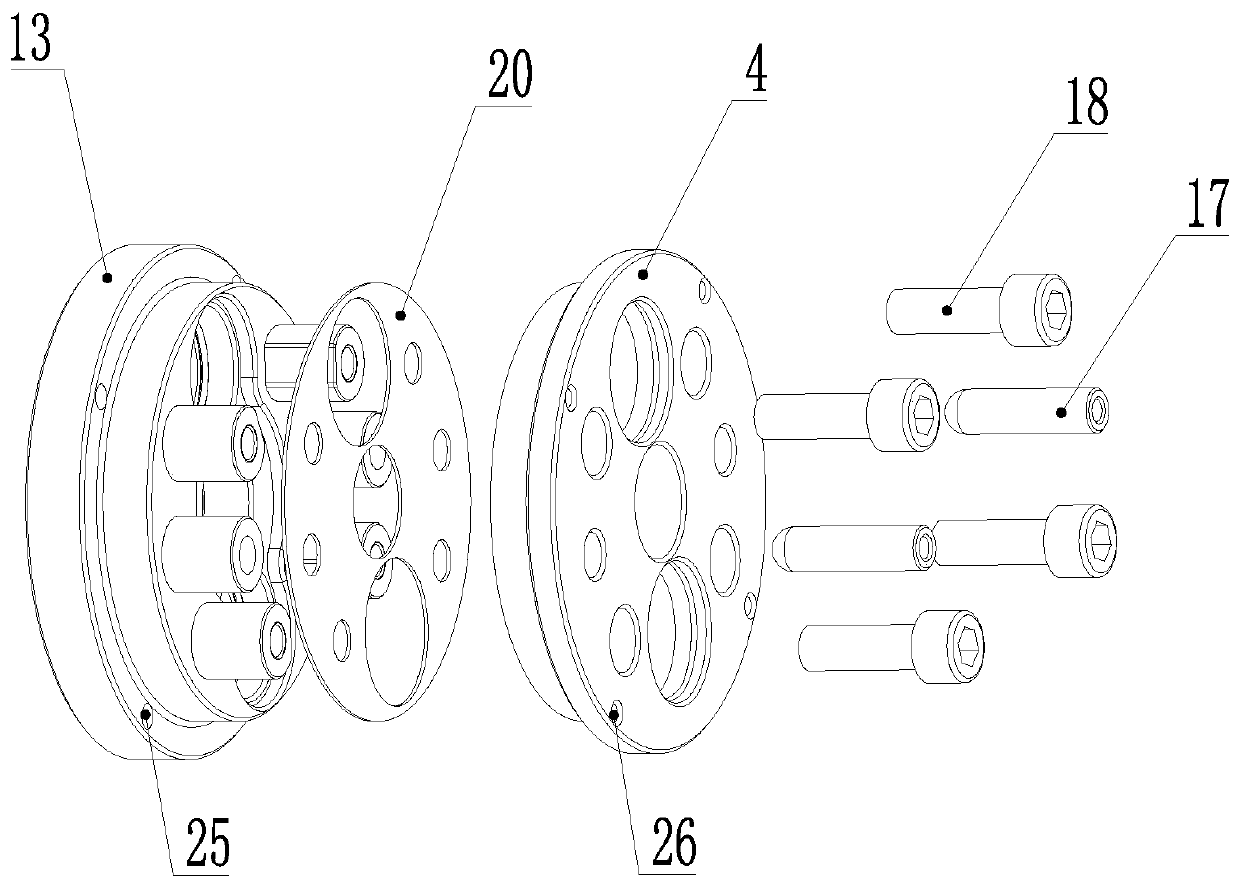

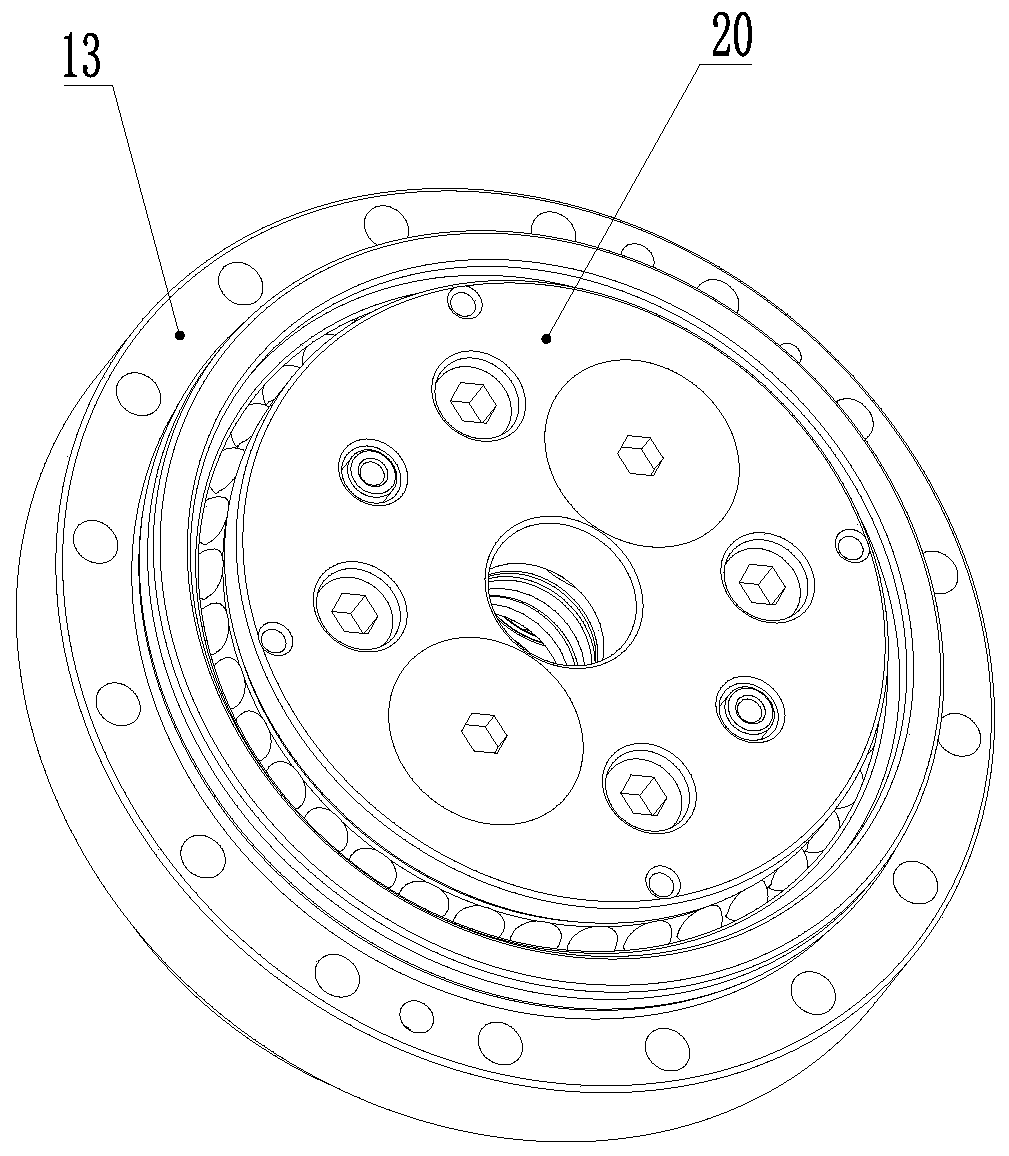

[0043] The difference between this embodiment and Embodiment 1 is that there are four first threaded through holes 25 and four second threaded through holes 26 , and they are evenly distributed on the circumference of the same diameter around the main shaft of the reducer. By setting such a ejection structure, it is convenient to disassemble the inner ring of the main bearing of the reducer accurately and completely, so as to prevent the inner ring from being damaged during the disassembly process, which is beneficial to repeated use.

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 lies in that: the chamfer 27 is arranged on one side of the large diameter of the pin hole 22 , corresponding to the rigid disc 4 . This can facilitate the positioning of the reducer spacer 6 and the rigid disk 4, so that the assembler can identify it, and it is beneficial to avoid assembly errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com