Fiber-optic gyroscope optical path welding performance detection method

A technology of fiber optic gyroscope and detection method, which is applied to Sagnac effect gyroscopes, measuring devices, instruments, etc., can solve problems such as effective evaluation of assembly performance, improve detection and troubleshooting efficiency, reduce the probability of abnormalities, and strengthen restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

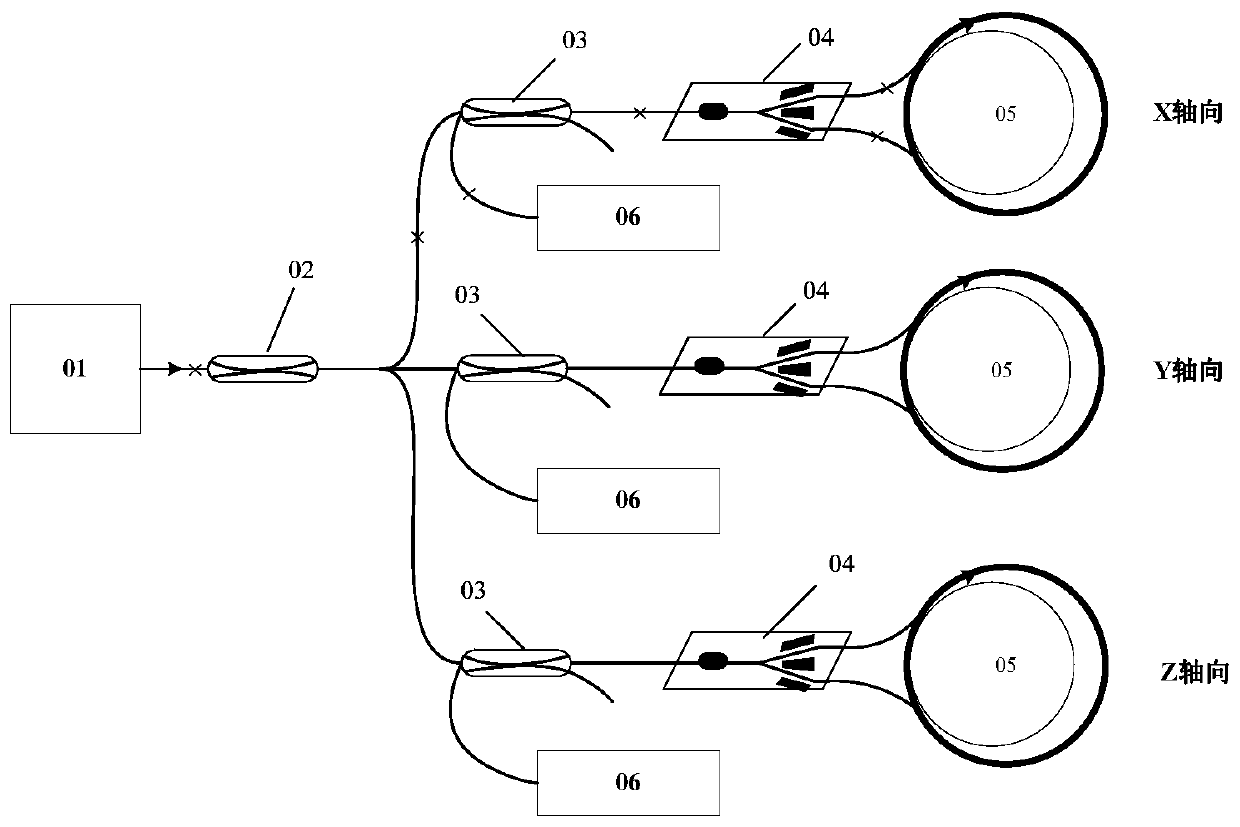

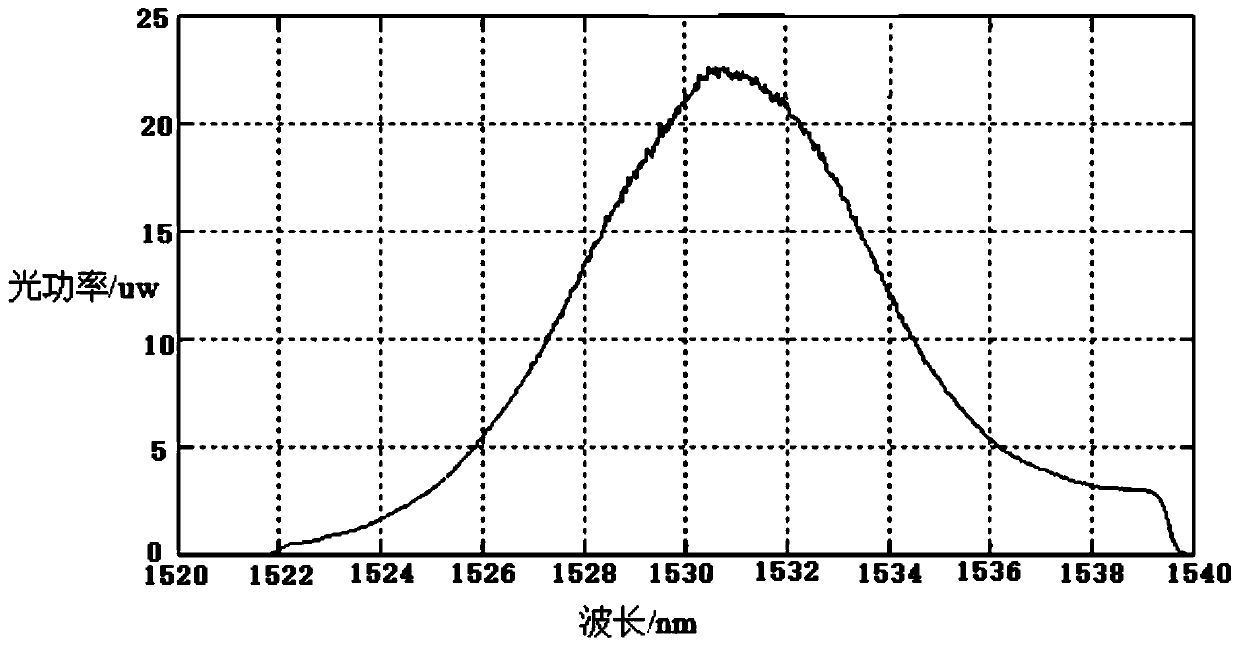

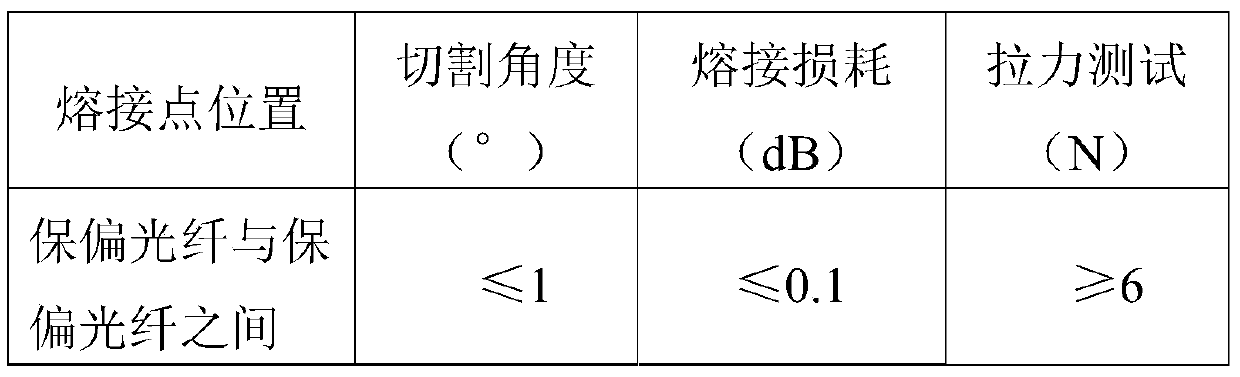

[0032] A method for detecting the fusion splicing performance of the optical fiber gyro optical path, which first detects the fusion splicing point between the polarization maintaining fiber and the polarization maintaining optical fiber that has the greatest influence, and then detects other fusion splicing points, without removing all components in the optical fiber gyroscope optical path during detection , using the spectrum of the spectrometer can intuitively judge whether there is an abnormality in the corresponding welding point. The detection method is intuitive and simple, easy to operate, and can be widely used in the field. The specific detection method is as follows:

[0033] S1, first complete the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| splice loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com