Apparatus and method for quality inspection of welded parts

A quality detection method and detection device technology, which are applied in the analysis of materials, the use of sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve the problems of high-speed train damage, low detection efficiency, and electromagnetic radiation harming health, etc., and achieve rapid quality detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A weldment quality inspection device mainly includes an excitation device, a measurement device and a control device. The detection device excites the shock wave vibration on the aluminum alloy welded parts through the excitation device, detects the vibration response signal, and judges the tissue structure information of the vibration excitation point area and the area between the vibration excitation point and the measurement point according to the vibration response signal, so as to weld the aluminum alloy parts for quality testing.

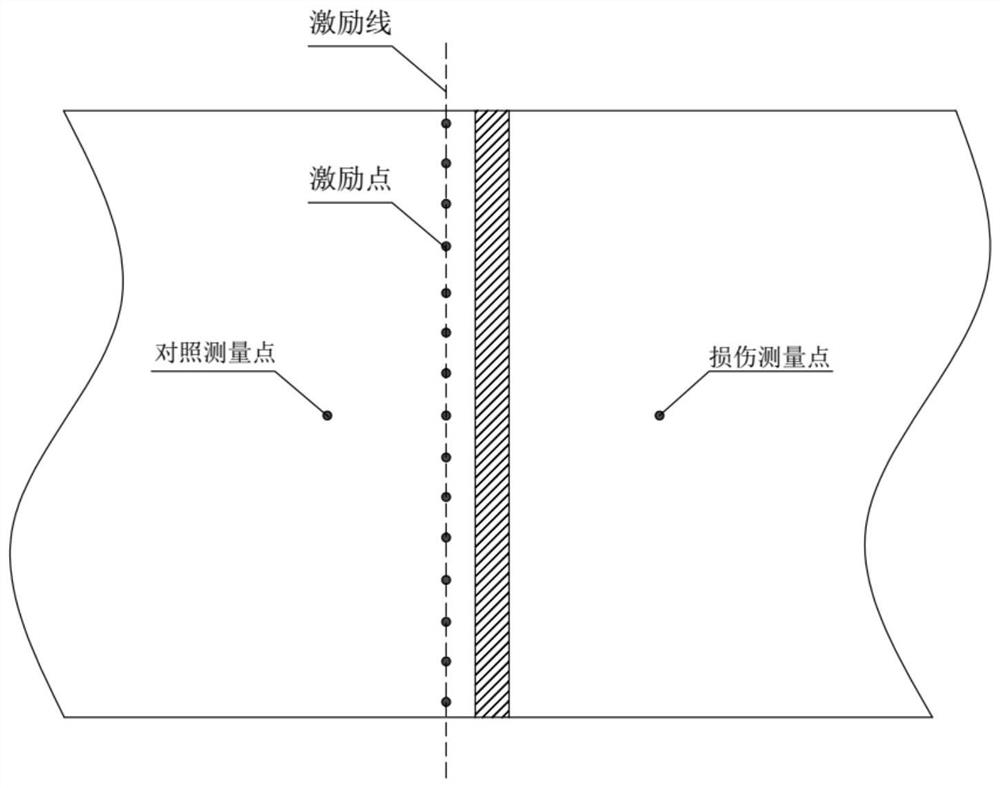

[0031] Such as figure 1 As shown, an excitation point is set at a distance of 3-8 mm from the edge of the heat-affected zone of the weld on one side of the weld of the weldment, and on the same horizontal plane as the excitation point, the comparison measurement is set symmetrically with the weld of the weld as the axis of symmetry Point R, damage measurement point M, control measurement point R, damage measurement point M are 20mm-100...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that the method for detecting the quality of welded parts described in this embodiment is mainly used for the quality detection of welded parts during service, including the following steps:

[0053] Step 1. After the high-speed train is produced and before it is put into use, for the aluminum alloy weldment installed on the high-speed train, an excitation signal is input at each excitation point g through the excitation device to obtain the frequency spectrum signal of each knocking force;

[0054] According to the calculation method of the time domain duration ratio, the frequency ratio of each order mode, and the frequency ratio of the center of gravity of the power spectrum, the ratio of the control measurement point R and the damage measurement point M corresponding to each excitation point g of the aluminum alloy weldment to be tested is obtained The duration ratio of the vibration response signal k″ t(g) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com