Method for determining high-temperature corrosion of boiler water-cooled wall through adherent gas components

A technology of high-temperature corrosion and gas composition, which is applied to the structural details of gas analyzers, combustion methods, and analysis of gas mixtures, etc., can solve unfavorable problems such as judgment, analysis and research of high-temperature corrosion of boiler water-cooled walls, and the lack of unity, so as to avoid Effects of economic loss, ease of operation, and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] The invention provides a method for discriminating high-temperature corrosion of boiler water-cooled walls through gas components attached to the walls, comprising the following steps:

[0044] (1) Measure the composition of gas attached to the wall in the designated area of the furnace, mainly including O2, CO, and H2S. Examples of test methods are as follows:

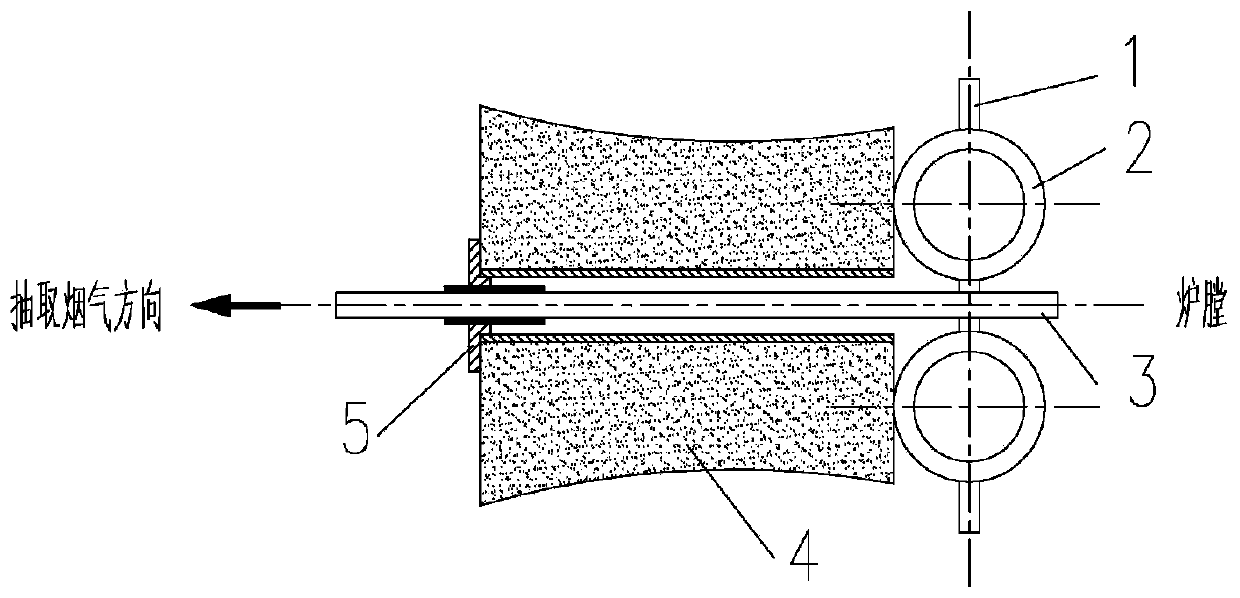

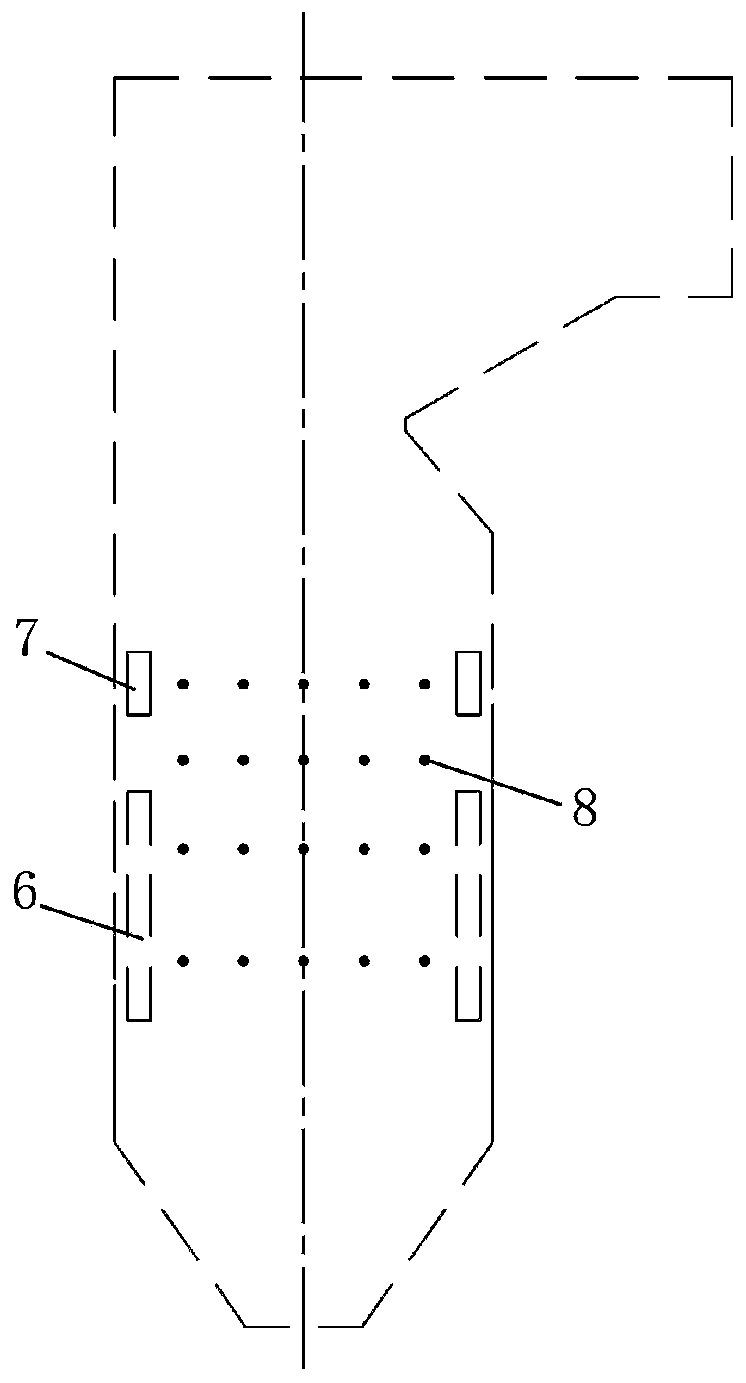

[0045] On the fin 1 between the boiler water wall tubes 2 The small hole, the wall-attached atmosphere measuring tube 3 adopts The 304 seamless stainless steel tube is made and passed through the small hole, and one end inserted into the inner side of the furnace is inserted to a depth of 5mm beyond the surface of the water-cooled wall tube 2, and the outer end of the furnace protrudes from the furnace wall insulation layer by 4 to 150mm. The connection and sealing are carried out by double-sided s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap