Low-profile broadband microstrip antenna based on metasurface

A technology of microstrip antenna and metasurface, which is applied in the direction of antenna, antenna coupling, antenna components, etc., can solve the problems affecting the quality of communication, and the conventional antenna cannot fully meet the requirements of modern communication, so as to solve the interference problems such as coupling and easy to carry Conformal, the effect of reducing the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

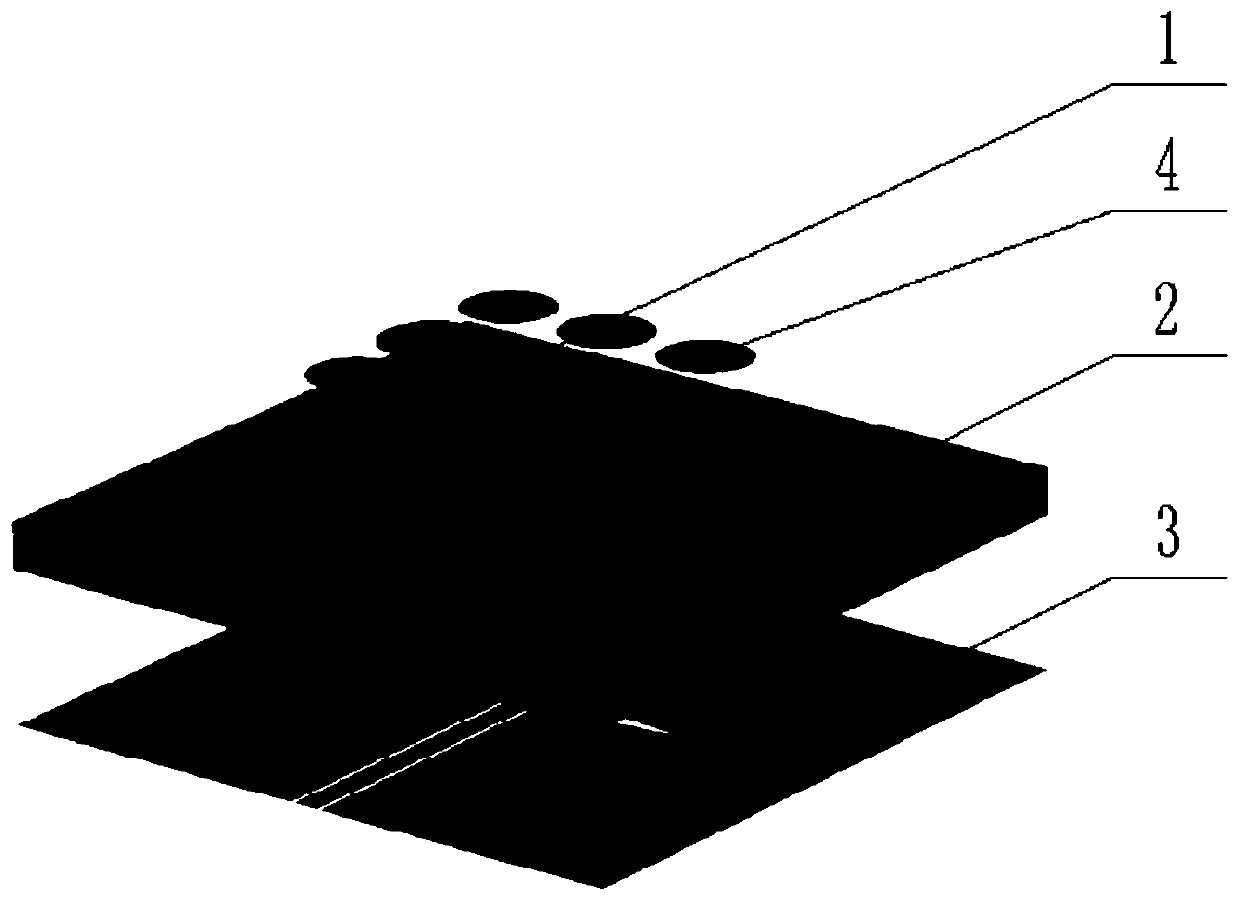

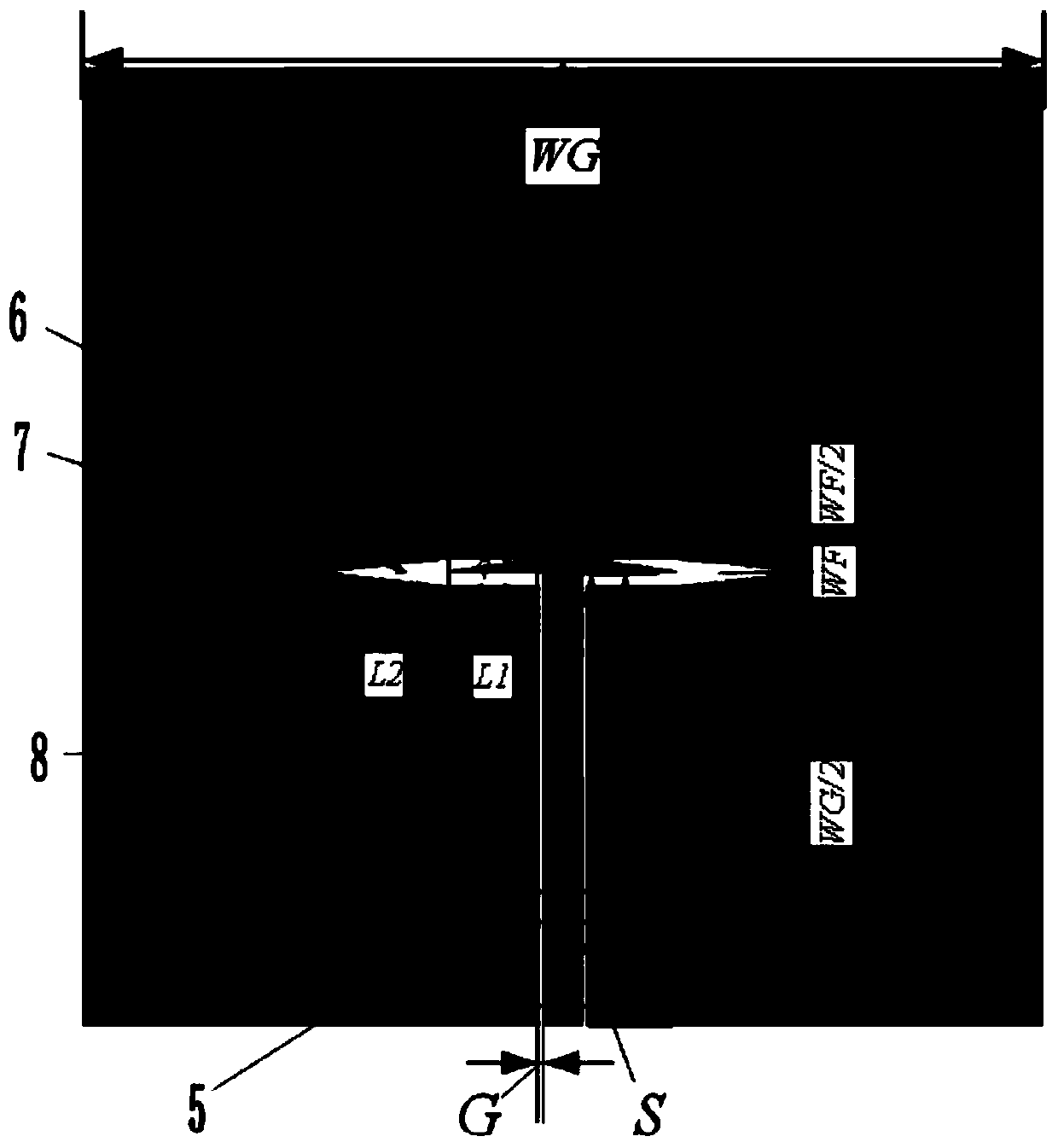

[0034] Embodiment 1: a kind of low profile broadband microstrip antenna based on metasurface, such as figure 1 As shown; including metasurface radiation layer 1, dielectric substrate layer 2 and feed layer 3 arranged in sequence from top to bottom; metasurface radiation layer 1 is mounted on the upper end of dielectric substrate layer 2, and feed layer 3 is mounted on the dielectric The lower end of the substrate layer 2; the metasurface radiation layer 1 contains nine circular radiation elements 4; the feed layer 3 includes CPW feeders 5, triangular metal branches 6, gradual coupling slots 7 and metal floor 8; the signal is input from the CPW feeder 5 , the signal is coupled to the metasurface radiation layer 1 through the triangular metal branch 6 and the gradual coupling gap 7, thereby forming a wider impedance bandwidth. The antenna adopts printed circuit board technology, in which the material of the radiation layer 1 and the feed layer 3 is metal copper, and the material...

Embodiment 2

[0039] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0040] The width S of the CPW feeder 5 is 1.5 mm. The feeder extends to the center of the plane and connects with the metal floor 8 to form a short circuit. The gap g between the feeder and the metal floor 8 is 0.2 mm. The triangular metal branch 6 is left-right symmetrical and directly connected to the feeder. The length L1 of the long right-angle side is 3mm, and the distance WF / 2 between it and the metal floor 8 is 0.5mm; the gradient coupling gap 7 is located in the center of the entire plane, and the gradient distance L2 is 4mm, symmetrical up and down, and the widest width at the gradient For WF, the narrowest width is 0.

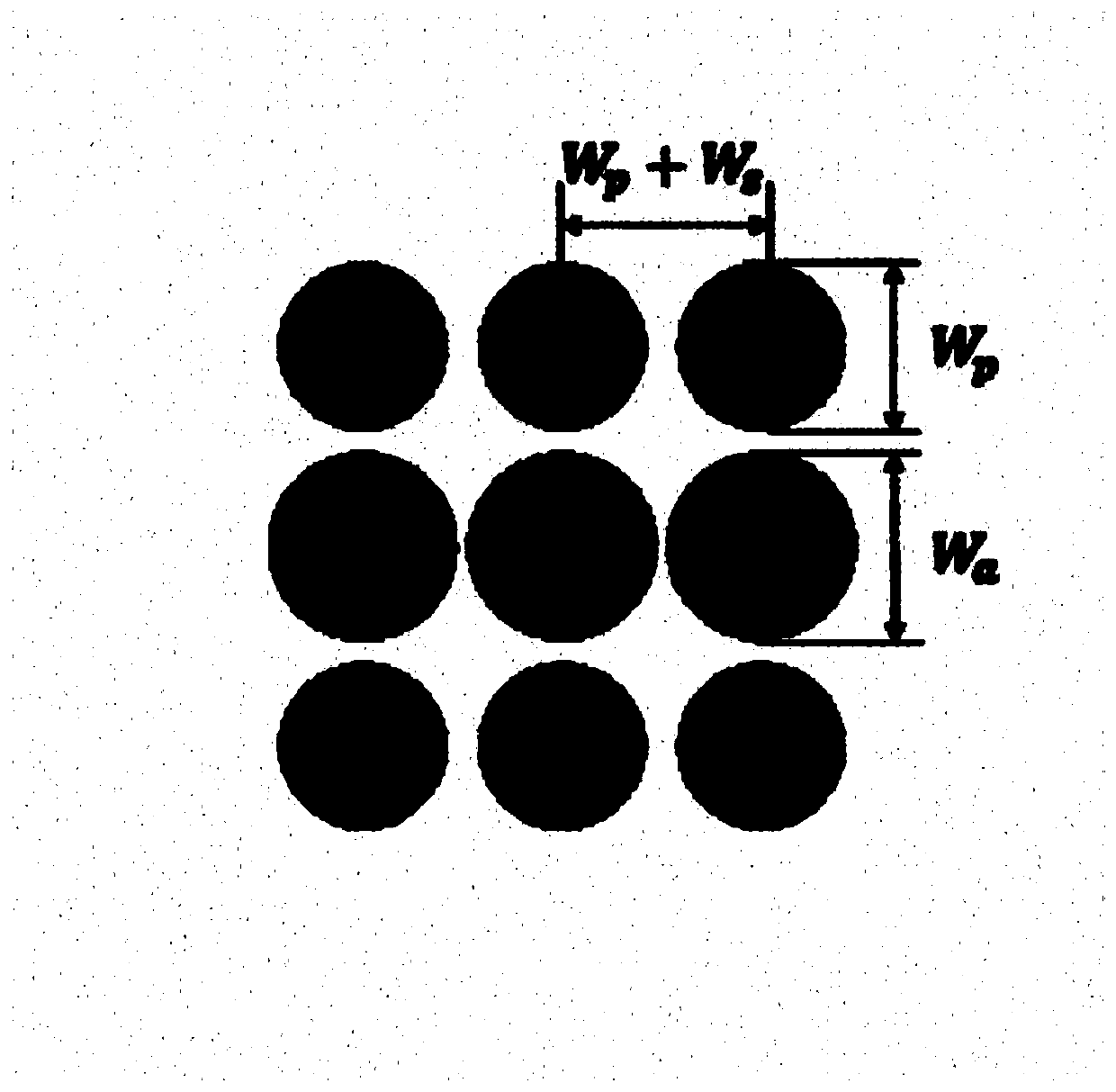

[0041] The distance between the centers of the upper and lower rows of adjacent circular radiation units 4 is a fixed value of 7mm, and the diameters of the upper, middle and lower rows of circular units are different. Among them, the diameter of the upper and lower row...

Embodiment 3

[0043] Embodiment 3: the difference between this embodiment and embodiment 1 is:

[0044] like figure 2 As shown: the width S of the CPW feeder 5 is 1.2mm, the feeder extends to the center of the plane and connects with the metal floor 8 to form a short circuit, the gap g between the feeder and the metal floor 8 is 0.3mm; The length L1 of its long right-angled side is 2.8mm, and the distance WF / 2 between it and the metal floor 8 is 0.6; the gradient coupling gap 7 is located in the center of the entire plane, and the gradient distance L2 is 3.7mm, which is symmetrical up and down and gradually The widest width is WF, and the narrowest width is 0.

[0045] like image 3 As shown, the 3x 3 circular radiation unit 4 is composed of a regular metasurface structure, the distance Wp+Ws between the centers of the upper and lower rows of adjacent circular radiation units 4 is a fixed value of 6.5mm, and the upper, middle and lower rows of circular units The diameters are different....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com