Motor system for reducing load transmission smoothness through power supply change control

A technology with variable and smooth power supply, applied in the field of motors, can solve problems such as increased motor load, unstable current control, and reduced motor stability, and achieve the effects of reducing vibration frequency, avoiding short circuits, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

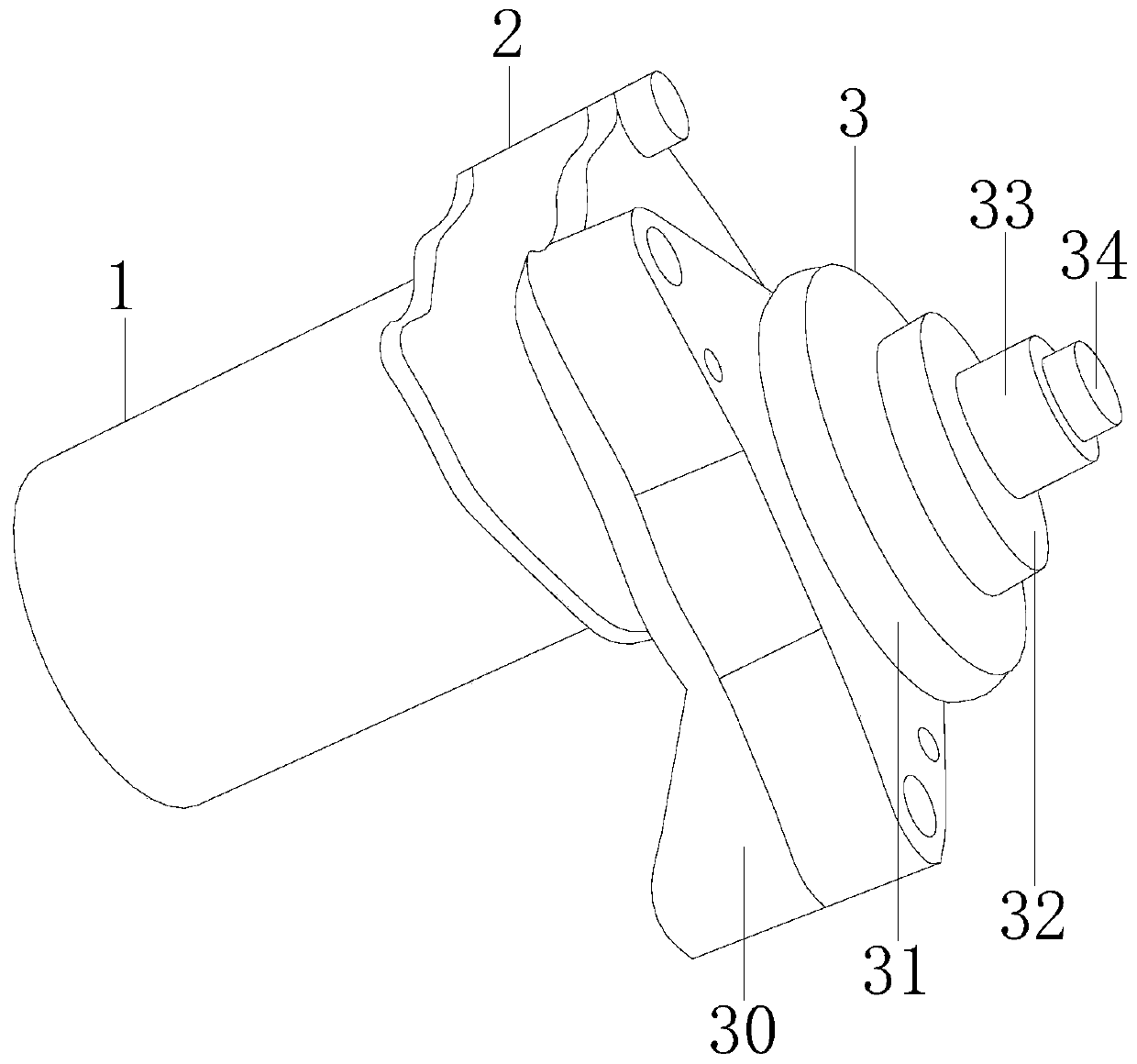

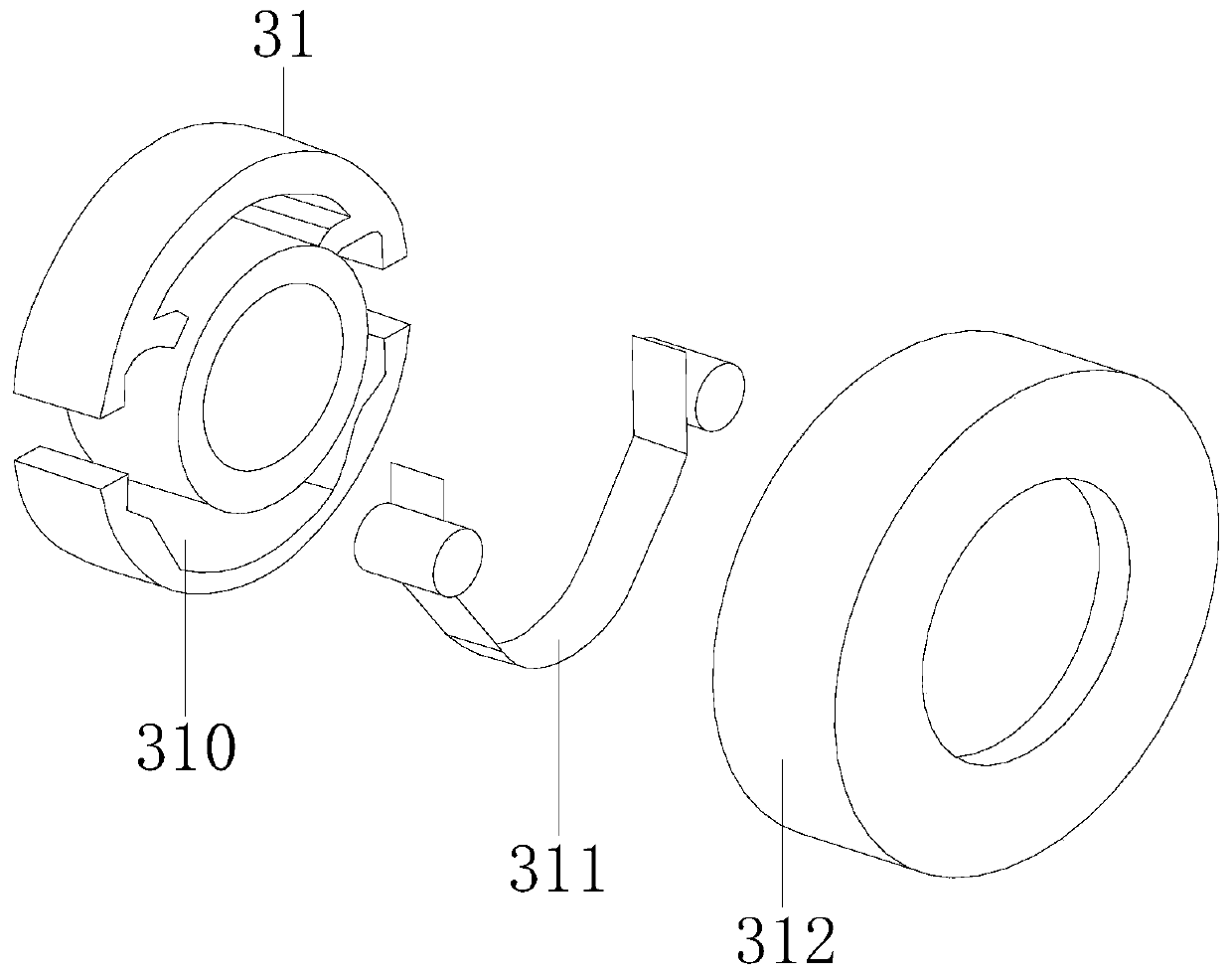

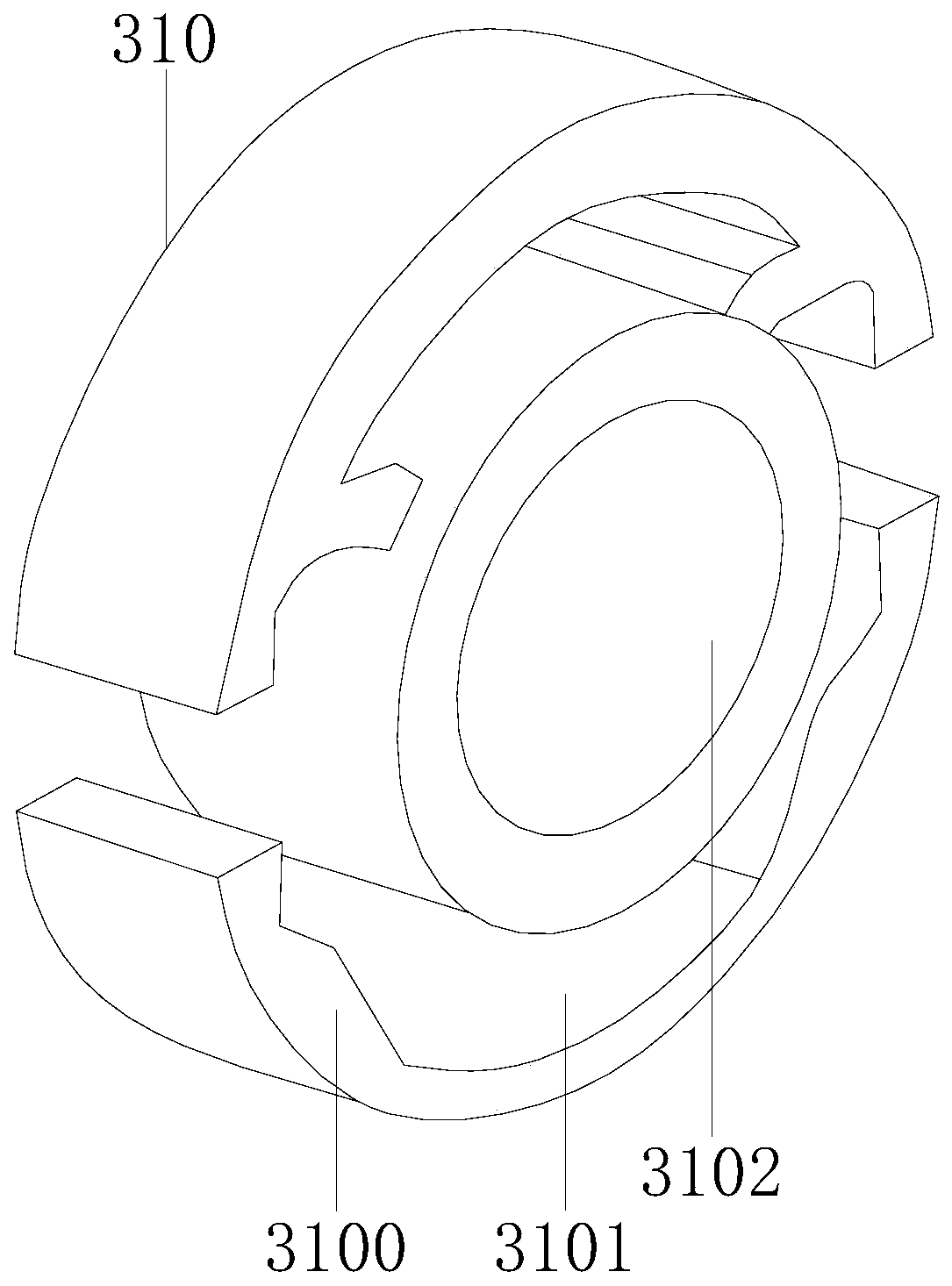

[0031] Example 1 see Figure 1-5 , the present invention provides a technical scheme of a motor system with power supply change control, reduced load transmission and smooth transmission: its structure includes a shell structure 1, a shell port 2, and a machine head 3, the shell structure 1 is installed and connected to the shell port 2, and the shell port 2. It is connected with the machine head 3 shafts. The machine head 3 is composed of a lock plate 30, a shaft plate 31, a lock plate 32, a rod ring 33, and a rod head 34. The lock plate 30 is embedded and connected with the shaft plate 31. The lock plate 32 passes through the shaft plate 31 and is embedded on the lock plate 30, and the rod ring 33 is attached to the rod head 34, and the rod head 34 passes through the shaft plate 31 and the lock plate 32 and is fixed on the lock plate 30. The shell mouth 2 is buckled and spliced with the lock plate 30, so that the machine head 3 and the shell structure 1 are on the same axi...

Embodiment 2

[0033] Example 2 see Figure 6-9 , the present invention provides a technical solution of a motor system with power supply variation control to reduce load transmission smoothness: its structure is a motor system with power supply variation control to reduce load transmission smoothness according to claim 1, characterized in that: the shell structure 1 It includes an iron shell 10, a fixed arm 11, an induction magnet 12, a shaft center device 13, an end cover 14, and a shrapnel 15. The iron shell 10 is locked with the fixed arm 11, and the fixed arm 11 is glued to the induction magnet 12. The fixed arm 11 plays the role of increasing torque and rotating balance transition. The induction magnet 12 acts on the induction magnetic field to record the rotation speed and data transmission. 14 is installed and connected, the elastic piece 15 fits and locks on the end cover 14 with the shaft center device 13, the shaft center device 13 includes a ring plate 40, a coil 41, an electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com