Automatic pressing device and method

A lamination equipment and pad-fitting technology, which is applied in multilayer circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of inability to realize automatic lamination production, dust and debris entering the inner circle, lamination sundries and pits Scrap and other issues, achieve good heat insulation and pressure equalization effect, reduce replacement, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

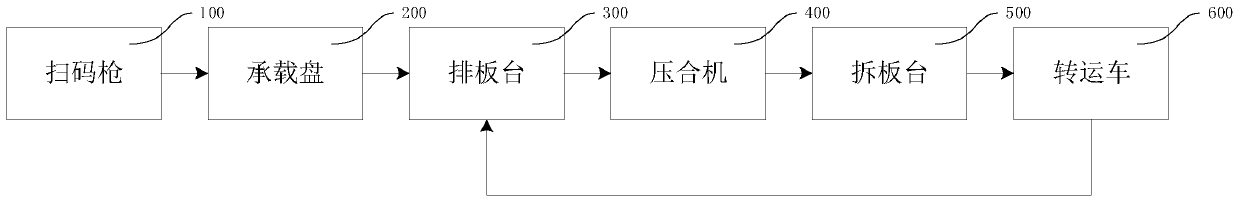

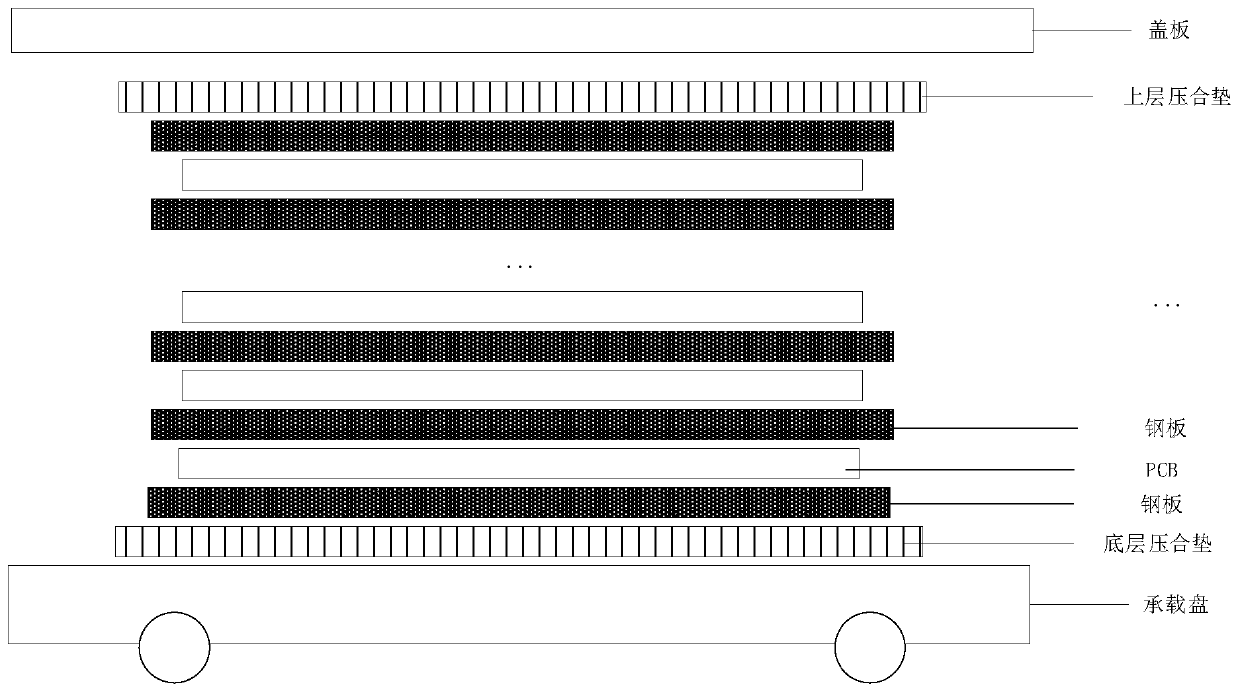

[0035] Embodiment 1 of the present invention provides an automatic pressing equipment, figure 1 A structural block diagram of an automatic pressing equipment provided in an embodiment of the present invention, such as figure 1 As shown, the equipment includes:

[0036] Code scanning gun 100: used to scan the first identification code information of the PCB board to be processed to obtain the production model information. The production model information includes: lamination procedure, number of stacked board layers, lamination pad model, and production size.

[0037] In this embodiment, the first identification code information may be a two-dimensional code or a barcode, which is used to encode the production model information of the PCB board to be processed, so as to facilitate production process control. Among them, the lamination program is the program required for lamination of the type of PCB board to be processed, and cooperates with related software to realize the con...

Embodiment 2

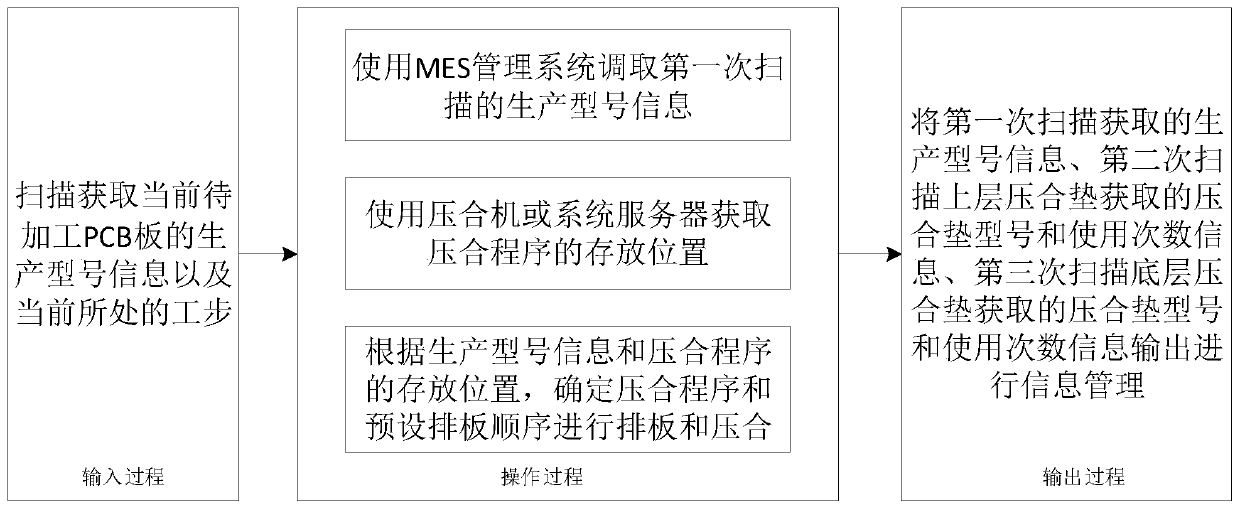

[0072] This embodiment provides an automatic pressing method, which is used in the automatic pressing equipment described in Embodiment 1, such as Figure 5 As shown, it is a flowchart for realizing the automatic pressing method of this embodiment, including:

[0073] S1: Obtain the production model information of the PCB board to be processed, and select the pressure pad model according to the production model information;

[0074] S2: Determine the height of the board arrangement according to the model of the pressing pad, and place multiple pressing pads and multiple PCB boards to be processed according to the preset board arrangement order and the height of the board arrangement, and perform automatic pressing operation.

[0075] Among them, the production model information of the PCB board to be processed is obtained in step S1, and the pressing pad model is determined according to the production model information, which specifically includes:

[0076] S11: Obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com