Welding control circuit and AC welding power supply

A technology for controlling circuits and welding power sources, applied in welding equipment, converting AC power input to AC power output, electrical components, etc., and can solve problems such as droplet splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the conventional consumable electrode type welding equipment, a short circuit occurs when the electrode comes into contact with the workpiece, at which time the voltage drops and the current rapidly increases. The huge welding current makes a lot of spatter when the liquid bridge is fused. In view of this, the present embodiment provides a welding control circuit that can greatly suppress the spatter generated when the liquid bridge is blown.

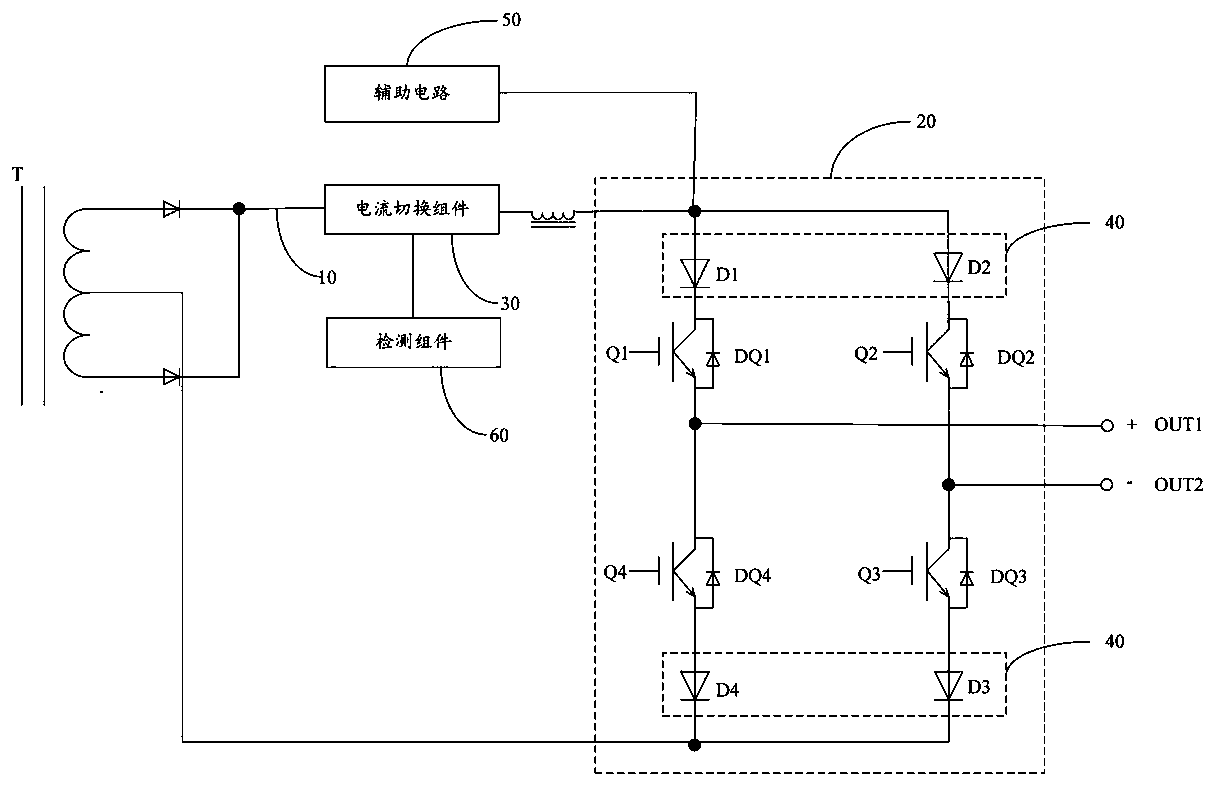

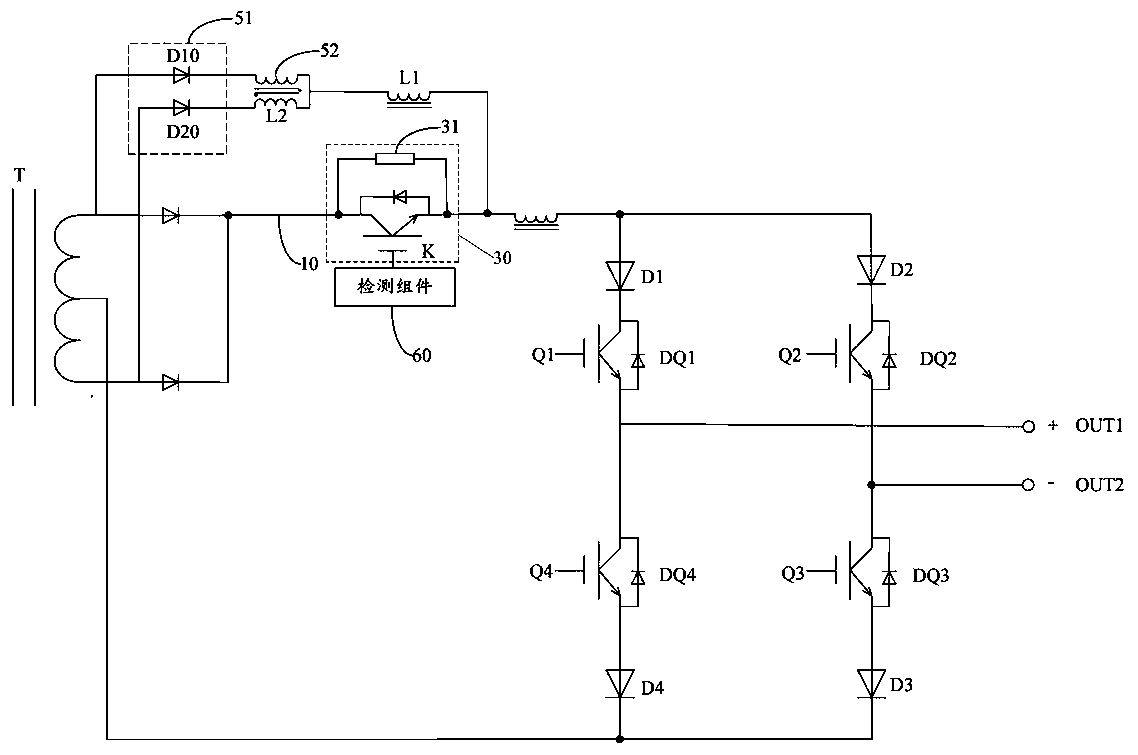

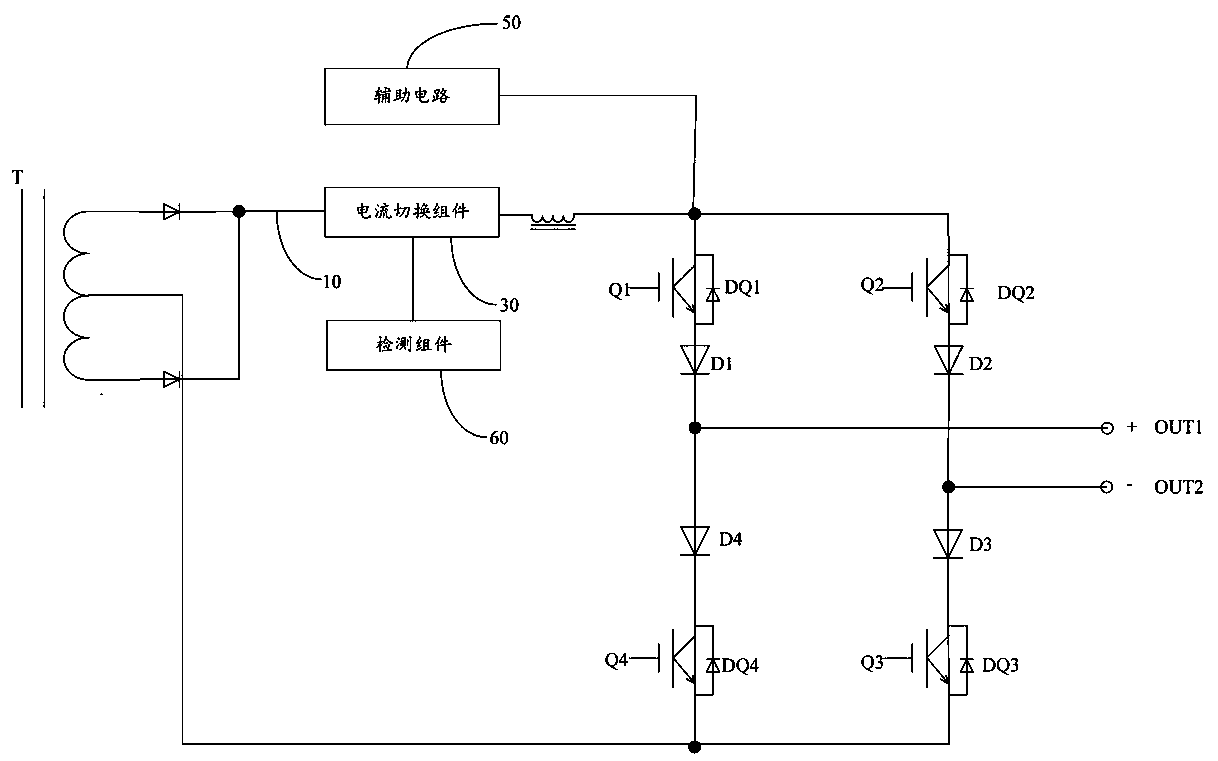

[0031] Such as figure 1 As shown, the welding control circuit provided by this embodiment includes an input main circuit 10 , an inverter circuit 20 , a current switching component 30 and a freewheeling blocking component 40 . The current switching assembly 30 is connected to the input main circuit 10 to adjust the output current of the inverter circuit 20, the current switching assembly 30 is configured to have at least a first working state and a second working state; during the short circuit, when the detected electrical p...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1 and its variations, the difference is that: Image 6 As shown, the auxiliary circuit 50 includes a constant current source 53 connected to the energy storage inductor L1 , and the constant current source 53 provides an auxiliary current for the auxiliary circuit that is smaller than the average current input to the main circuit 10 .

[0055] Similarly, the setting of the constant current source 53 makes a small current flow through the auxiliary circuit 50 during the non-pulse base period, and the inductance generated by the small current on the energy storage inductance L1 will not affect the characteristics of the welding current pulse. During the pulse base period, the inductance generated by the small current on the energy storage inductor L1 effectively reduces the ripple of the base current.

[0056] To sum up, the welding control circuit and the current switching component connected in series in the input main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com