Micro-foam drilling fluid

A drilling fluid and microbubble technology, applied in the field of drilling fluids, can solve the problems of insufficient compression resistance, the need for further enhancement of leakage prevention, and the lack of a treatment agent for bonding and filming to seal micro-fractures on the well wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

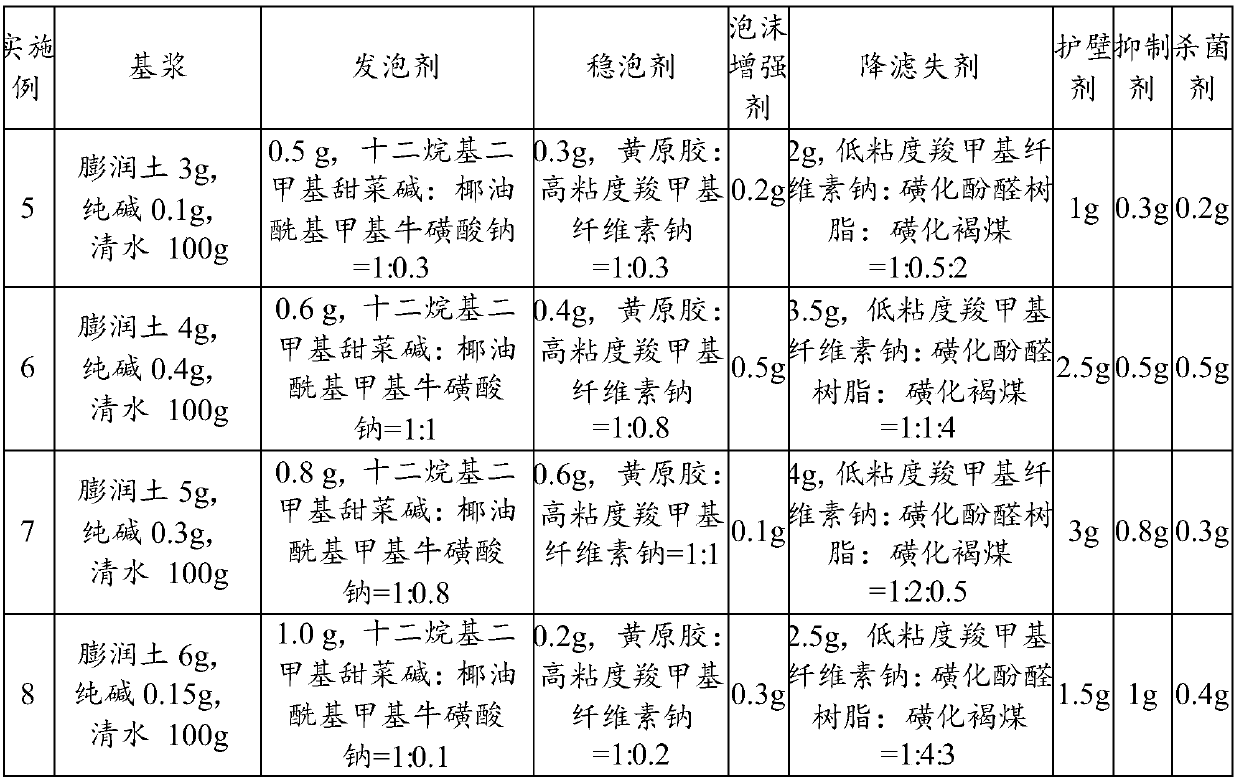

Examples

Embodiment 1

[0074] The preparation of embodiment 1 foam enhancer

[0075] Dissolve 10g of dodecyldimethylallyl ammonium chloride in 100g of clear water for later use;

[0076] Dissolve 80g of acrylamide and 10g of 2-acrylamido-2-methylpropanesulfonic acid in 250g of clear water for later use;

[0077] Dissolve 1g of ammonium persulfate in 50g of clear water for later use;

[0078] Add 0.1 g of mercaptoacetic acid, dodecyldimethylallyl ammonium chloride solution, acrylamide and 2-acrylamido-2-methylpropanesulfonic acid solution into the reaction vessel and raise the temperature to 60°C, then place Ammonium persulfate solution was added to the reaction system, the system was heated to 90° C. for 1 hour, and the pH value of the solution was adjusted to 8 with NaOH to obtain a foam enhancer with an average molecular weight of 50,000 and a solid content of 20%.

Embodiment 2

[0079] The preparation of embodiment 2 wall protecting agent

[0080] In a four-neck flask, add 15 g of acrylamide, 2.1 g of sodium dodecylbenzenesulfonate, and 205 g of distilled water, and stir evenly to obtain an aqueous phase;

[0081] 15.0 g of polystyrene foam and 2.1 g of octylphenol polyoxyethylene ether were dissolved in 60.0 g of butyl methacrylate to obtain an organic phase;

[0082] At 45°C, evenly add the above organic phase to the water phase dropwise within 30 minutes, emulsify at 600rpm for 1 hour, then raise the temperature to 60°C, pass N 2 After 30 minutes, 5 g of aqueous solution containing 0.27 g of azobisisobutylamidine hydrochloride was added, and the reaction was stopped after 6 hours of reaction to obtain a wall-protecting agent.

Embodiment 3

[0083] The preparation of embodiment 3 inhibitors

[0084] Dissolve 100g of acrylamide in 300g of water, stir well, add 50g of dimethylamine and react at room temperature for 2 hours, then raise the temperature to 35°C, add 50g of epichlorohydrin to the reactor in batches, and raise the temperature of the obtained solution to 60°C React for 1 hour, then add 10 mL of aqueous solution containing 1.5 g of ammonium persulfate, heat up to 90° C. and react for 0.5 hour to obtain the inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com