Recyclable Microbubble Drilling Fluid

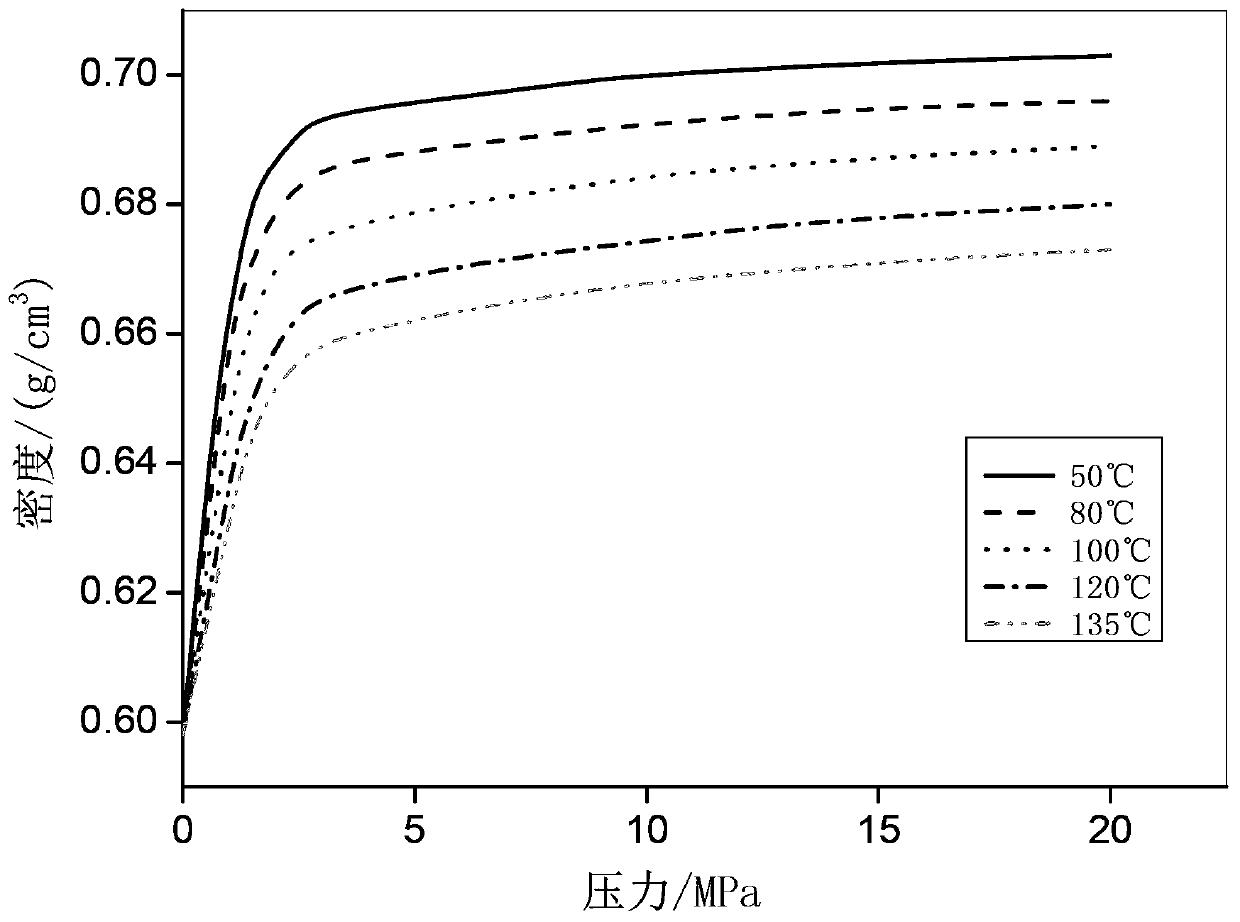

A drilling fluid and microbubble technology, applied in the field of oilfield drilling fluids, can solve the problems of increased bottom hole density of drilling fluids, temperature resistance below 120°C, affecting drilling construction safety, etc. The effect of strong compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

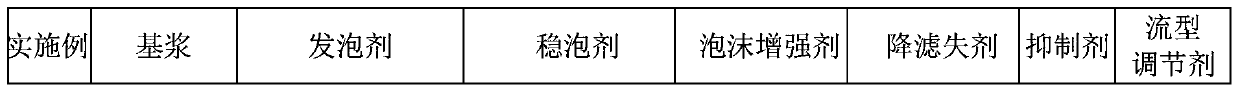

Examples

Embodiment 1

[0018] Add 6g of bentonite and 0.3g of soda ash to 100g of clear water, stir at high speed for 2 hours, and place it at room temperature for 24 hours to obtain the base slurry (1). - Sodium alkenyl sulfonate: fatty alcohol polyoxyethylene ether sodium sulfate = 1:0.3:0.8 mass ratio mixed), 0.5g foam stabilizer (made of Wenlun rubber: high viscosity sodium carboxymethyl cellulose = 1: 1 mass ratio), 0.2g foam enhancer (mixed with lauryl alcohol: triethanolamine = 1:0.5 mass ratio), 3g fluid loss control agent (made of low viscosity sodium carboxymethylcellulose: sulfonated Phenolic resin: sulfonated lignite = 1:2:2 mass ratio mixed), 0.2g inhibitor and 0.3g flow regulator are added to the base slurry (1) in sequence, and the treatment agent is mixed evenly with a stirrer for use. The inhibitor is a copolymer whose molar ratio is acrylamide: dimethylamine: epichlorohydrin = 1:0.5:0.5, with a relative molecular mass of 50,000; the flow regulator is acrylic acid whose molar ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com