A tubular reactor

A shell-and-tube reactor and the technology of the reactor are applied in the field of reactors, which can solve the problems of potential explosion of combustible gas raw materials, uneven gas-liquid flow field/temperature distribution, uneven heat distribution, etc., so as to avoid the self-polymerization explosion of feed materials. The effect of eliminating hidden dangers, eliminating dead zones and stagnant layers, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

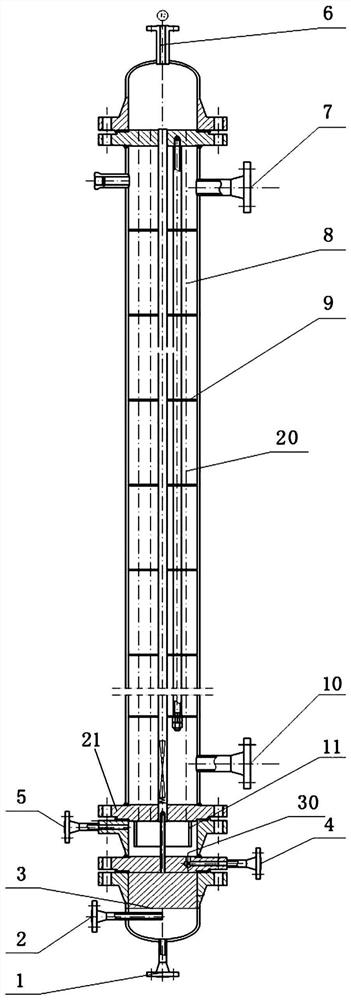

[0044] Ethylene carbonate synthesis: according to figure 1 , The gas-liquid-solid multiphase tubular reactor is installed vertically, with 2400 tubes evenly distributed inside the reactor, the inner diameter of the tubes is 20mm, the distance between the tubes is 15mm, and the length of the tubes is 8000mm. The number of baffles is 10, forming an angle of 90° with the shell. Each column is filled with an organic polymer-supported ionic liquid catalyst (a polystyrene resin-supported 1,2,4-triazole bromide-based ionic liquid catalyst is specifically used in the present invention). CO 2 It enters from the gas inlet and is evenly distributed into the tube reactor through the gas inlet distributor. Ethylene oxide (EO) is fed tangentially through the liquid feed port, and the baffle is located at the top of the liquid feed chamber and is 10mm away from the bottom of the liquid feed chamber. The tangential feeding and baffle adjustment method is used to feed the feed to eliminate ...

Embodiment 2

[0046] Sulfonation (sulfation) reaction: according to figure 1 , The tube-and-tube reactor is installed vertically, with 2,200 tubes evenly distributed inside the reactor, the inner diameter of the tubes is 25mm, the distance between the tubes is 12mm, and the length of the tubes is 6m. The number of baffles inside the tube-and-tube reactor is 5, and it forms an angle of 90° with the shell. SO 3 / Nitrogen mixture (SO 3 The volume fraction is 25%) enters from the gas inlet, and is evenly distributed into the tube-and-tube reactor through the gas inlet distributor. The organic phase is fed tangentially through the liquid feed port, and the baffle is located at the top of the liquid feed chamber and 8mm from the bottom of the liquid feed chamber. The tangential feed baffle is used to adjust the feed to eliminate the disturbance caused by the feed, and the organic liquid phase can be evenly distributed into each tube, SO 3 Uplink reacts with the organic liquid phase to produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com