Waste glass recovery device

A recycling device and waste glass technology, applied in the direction of glass recycling, mechanical material recycling, recycling technology, etc., can solve the problems that affect the subsequent recycling of waste glass and the poor quality of waste glass recycling, so as to reduce the cost of installation, reduce blockage, The effect of reducing the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

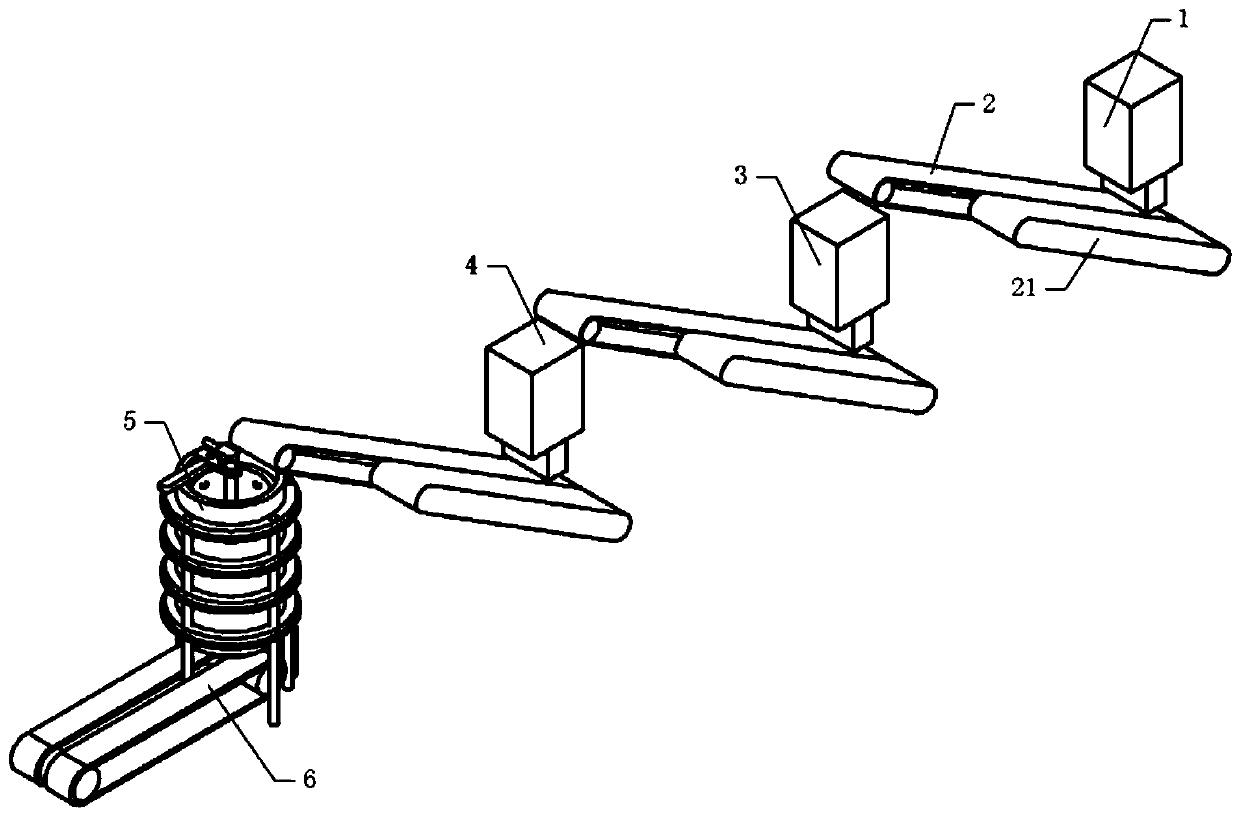

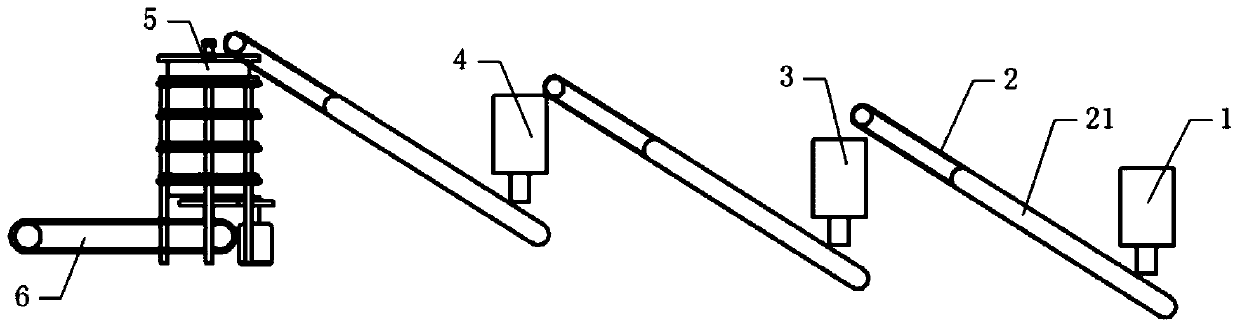

[0040] Basic as attached figure 1 And attached figure 2 As shown, a waste glass recycling device includes a frame (not shown in the figure), and the frame includes a cleaning mechanism, a magnetic separation mechanism 4, a stirring mechanism 3 and a storage box 1 from left to right, and two adjacent A conveyor belt 2 is arranged between the two mechanisms, and the conveyor belt 2 is installed on the frame, and one side of the conveyor belt 2 is provided with a workbench 21 fixed on the frame by fastening bolts.

[0041] Material storage box 1 is fixed on the frame by fastening bolt, and material storage box 1 is positioned at the top of conveyor belt 2 and broken waste glass, i.e. glass shards, is housed in the material storage box 1.

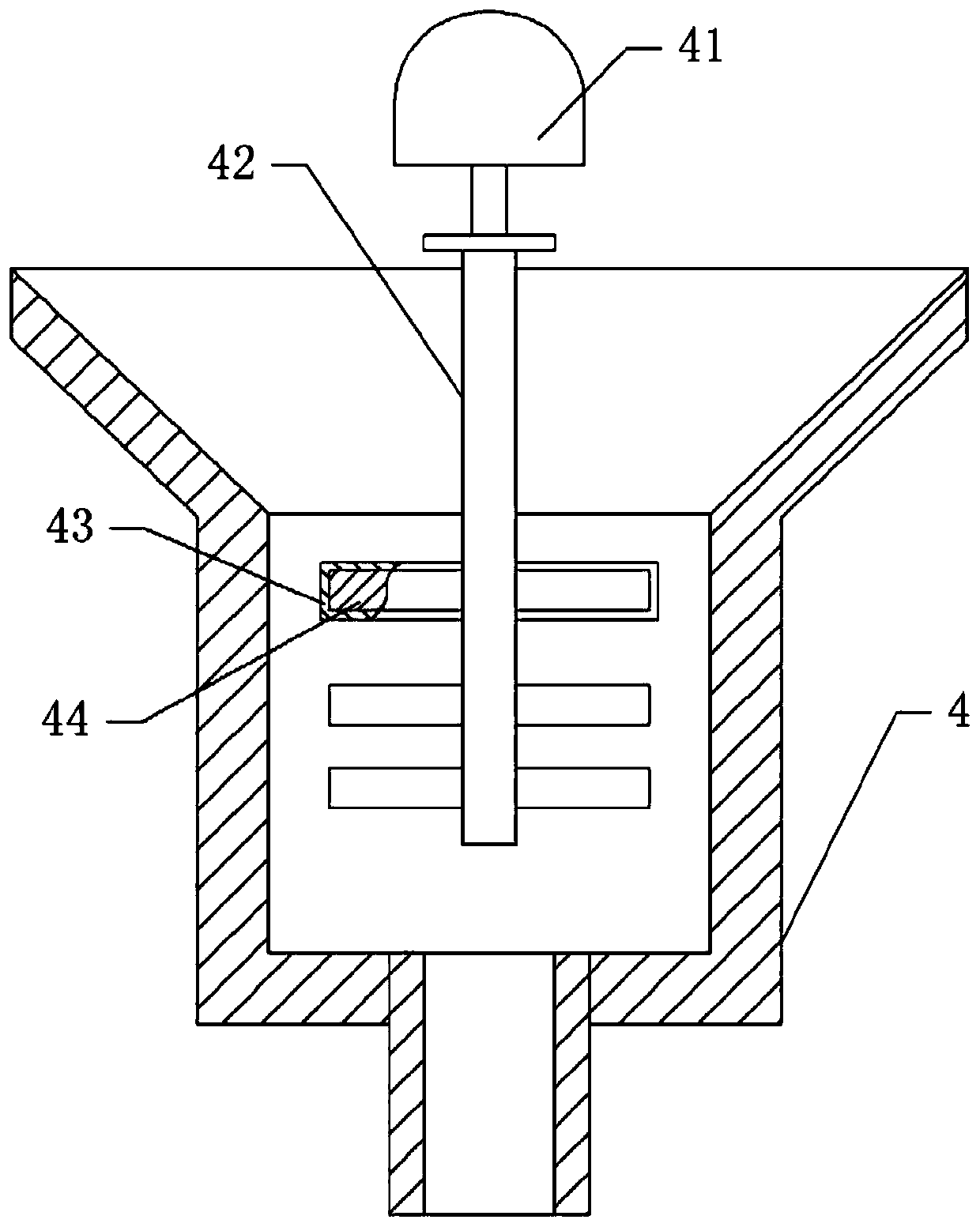

[0042] as attached image 3 As shown, the stirring mechanism 3 and the magnetic separation mechanism 4 include a stirring box fixed on the frame by fastening bolts, the top of the stirring box is provided with a tapered feed inlet in longitu...

Embodiment 2

[0055] The difference between embodiment two and embodiment one is that, as attached Figure 7 And attached Figure 8 As shown, the output shaft of the single-phase motor 54 is coaxially welded and fixed with a cam 81, and the gear 56 is horizontally slidably connected with a push plate 83 that is resisted by the cam 81. The groove of sliding fit, the elastic piece is arranged between the push plate 83 and the side wall of the cleaning bucket 5, the elastic piece is a spring 84 in the present embodiment, and the two ends of the spring 84 are respectively welded on the side of the pushing plate 83 and the cleaning bucket 5 on the wall. The right side of push plate 83 is welded with cleaning shaft 82, and one side of conveyer belt 2 is provided with the blower fan that is fixed on the frame by fastening bolt.

[0056] The specific implementation process is as follows:

[0057] The single-phase motor 54 drives the cam 81 to rotate, and the cooperation of the cam 81 and the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com