Steel structure anti-corrosive construction technology

A construction technology and steel structure technology, applied in the direction of anti-corrosion coatings, coatings, devices for coating liquid on the surface, etc. The bonding force and corrosion resistance of the steel structure surface, affecting the anti-corrosion performance of the steel structure, etc., to achieve the effect of improving the anti-corrosion effect, improving the anti-corrosion performance, and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

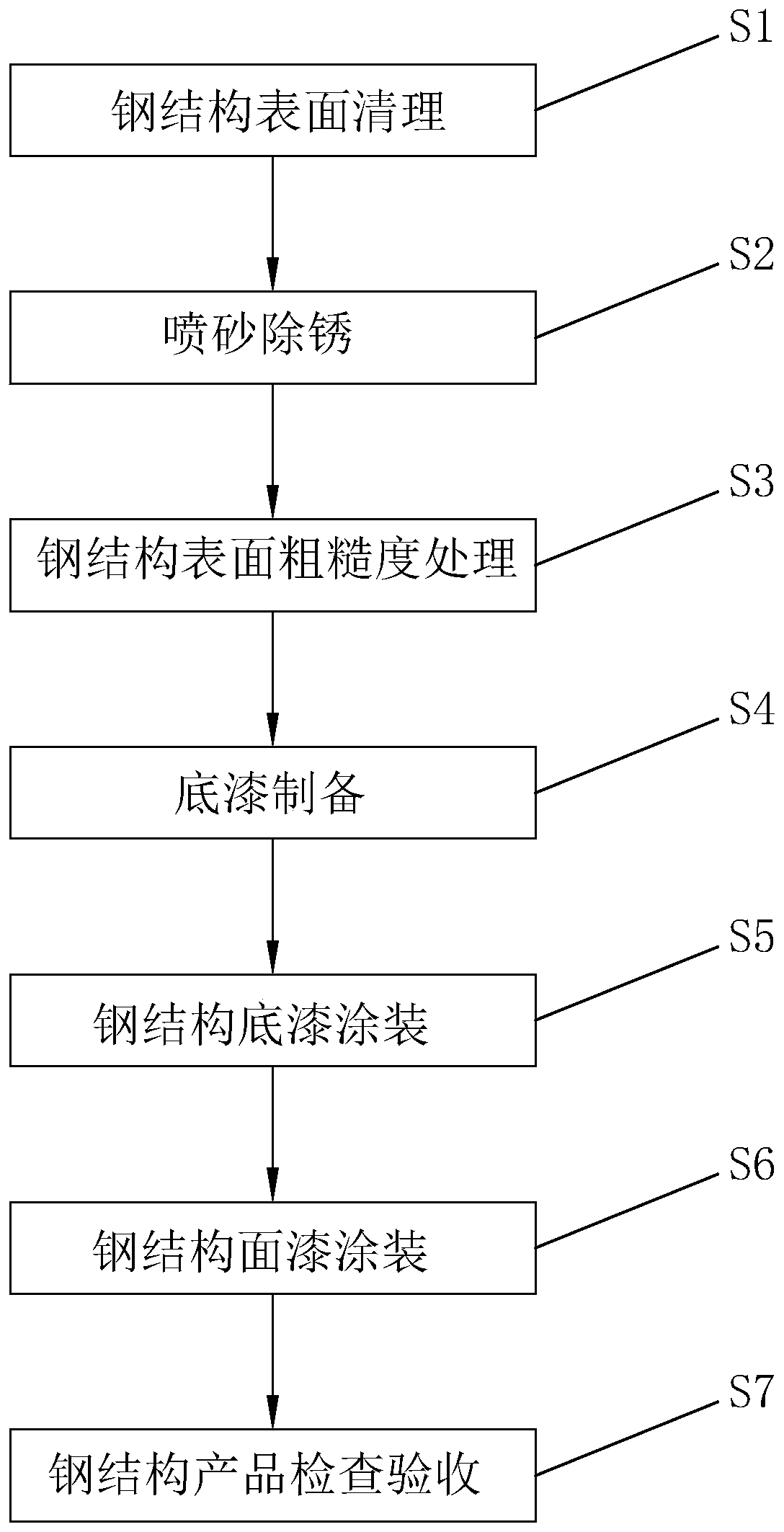

[0061] A steel structure anticorrosion construction process, comprising the following steps:

[0062] S1. Surface cleaning of steel structure: Clean up the scale, welding spatter, oil and dust on the parts to be painted.

[0063] S2. Sandblasting and derusting: place the steel structure on the stirrup, fill the sand tank with quartz sand, keep the pressure of the air compressor at 0.5Mpa, keep the spray angle at 40°, and place the nozzle at a distance of 120mm from the surface of the steel structure. Quartz sand is evenly sprayed onto the surface of the steel structure until the surface of the steel structure reveals a metallic luster, and then the rust dust and residual abrasives are removed with a brush.

[0064] S3. Surface roughness treatment of the steel structure: Use a grinding wheel to grind the surface of the steel structure to make the steel structure have a certain surface roughness, and then use cotton yarn to clean the residual abrasive on the surface of the steel...

Embodiment 2

[0075] A steel structure anticorrosion construction process, the difference from Embodiment 1 is that it includes the following steps:

[0076] S1. Surface cleaning of steel structure: Clean up the scale, welding spatter, oil and dust on the parts to be painted.

[0077] S2. Sandblasting and derusting: place the steel structure on the stirrup, fill the sand tank with quartz sand, keep the pressure of the air compressor at 0.5Mpa, keep the spray angle at 50°, and place the nozzle at a distance of 130mm from the surface of the steel structure. Quartz sand is evenly sprayed onto the surface of the steel structure until the surface of the steel structure reveals a metallic luster, and then the rust dust and residual abrasives are removed with a brush.

[0078] S3. Surface roughness treatment of the steel structure: Use a grinding wheel to grind the surface of the steel structure to make the steel structure have a certain surface roughness, and then use cotton yarn to clean the res...

Embodiment 3

[0089] A steel structure anticorrosion construction process, the difference from Embodiment 1 is that it includes the following steps:

[0090] S1. Surface cleaning of steel structure: Clean up the scale, welding spatter, oil and dust on the parts to be painted.

[0091] S2. Sand blasting and derusting: place the steel structure on the stirrup, fill the sand tank with quartz sand, keep the pressure of the air compressor at 0.6Mpa, keep the spray angle at 70°, and the distance between the nozzle and the surface of the steel structure is 150mm. Spray evenly onto the surface of the steel structure until the surface of the steel structure reveals a metallic luster, and then use a brush to remove rust and residual abrasives.

[0092] S3. Surface roughness treatment of the steel structure: Use a grinding wheel to grind the surface of the steel structure to make the steel structure have a certain surface roughness, and then use cotton yarn to clean the residual abrasive on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com