Numerical control milling machine with cleaning mechanism

A CNC milling machine and cleaning mechanism technology, applied in the direction of dryers, cleaning methods and tools, metal processing machinery parts, etc., can solve the problems of inability to perform quick cleaning, take a long time, and have many gaps in the workbench, etc., to achieve cleaning effect Significant, strengthen the effect of cleaning, improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

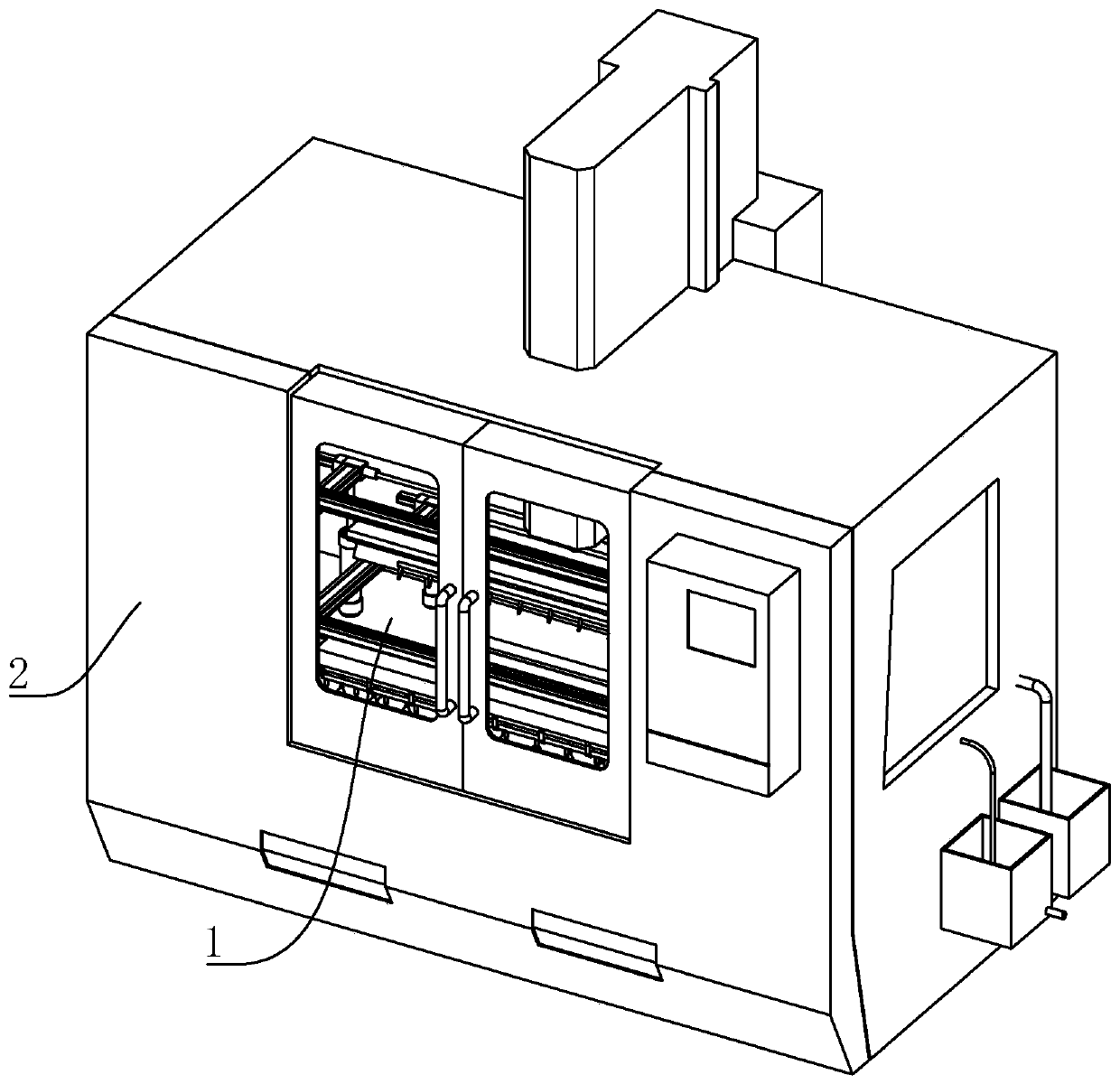

[0040] refer to figure 1 , is a CNC milling machine with a cleaning mechanism disclosed in the present invention, including a working platform 1 and a casing 2, the casing 2 is arranged outside the working platform 1, the casing can prevent debris from splashing, and at the same time can play a certain role protective effect.

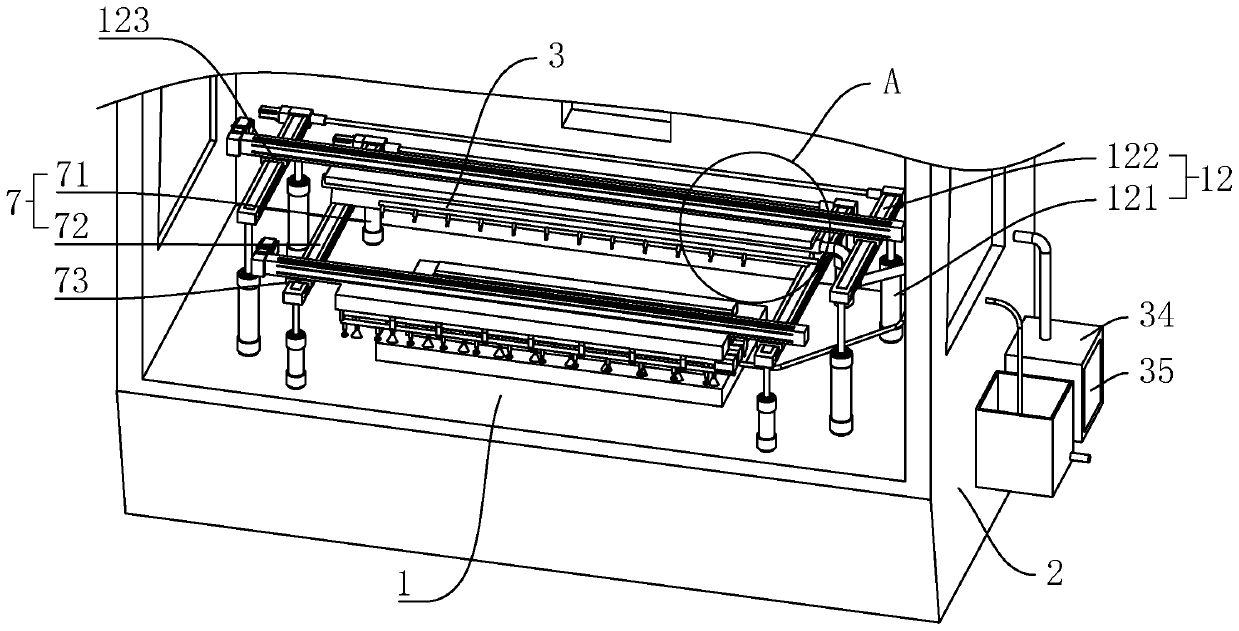

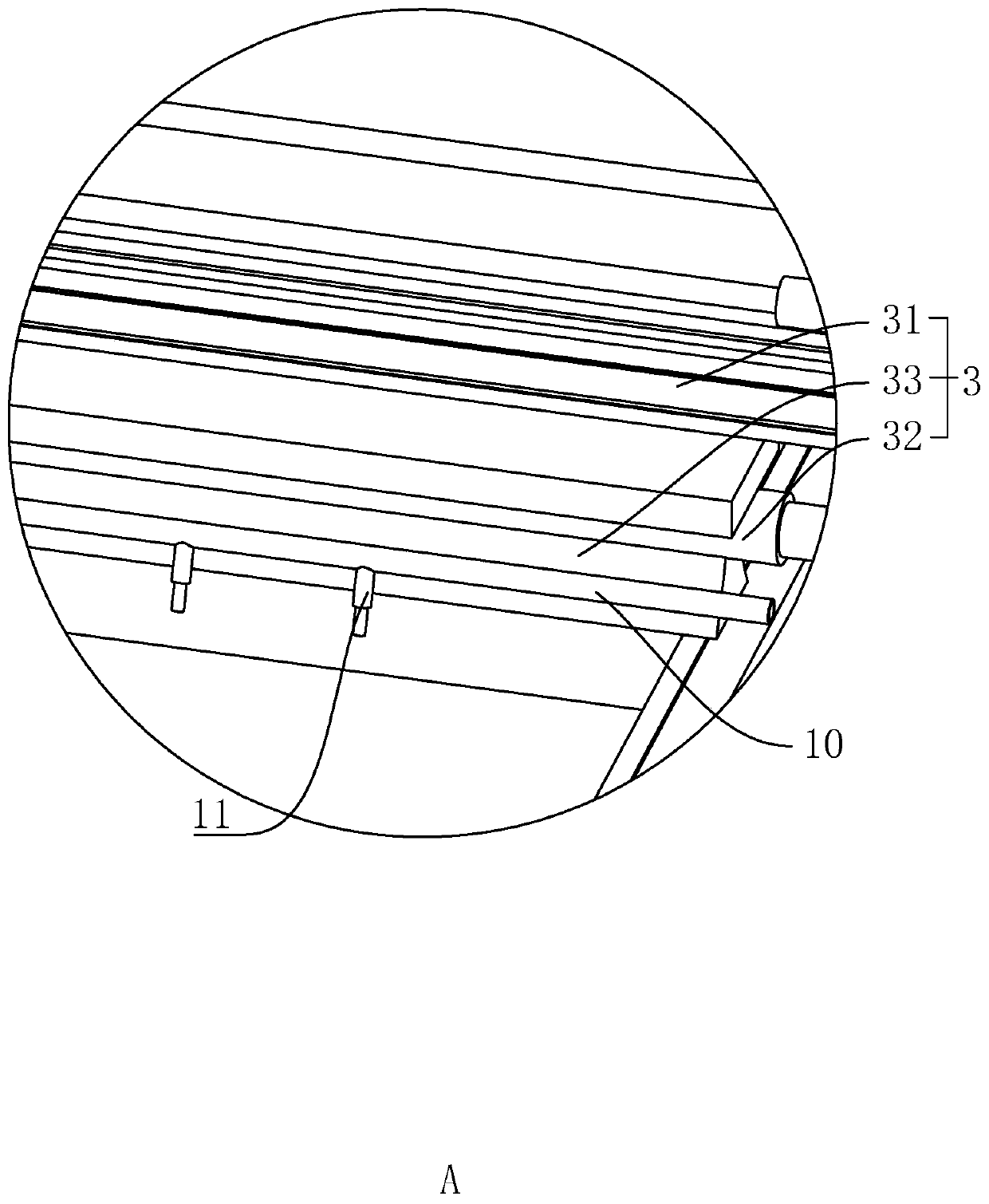

[0041] refer to figure 2 , the upper end of the working platform 1 is provided with a first supporting device 7 and a second supporting device 12, the second supporting device 12 is linked with a chip removal device 3, and the second supporting device 12 can drive the chip removal device 3 to slide on the working platform 1 .

[0042] refer to figure 2 , the first supporting device 7 includes two sets of first oil cylinders 71 fixedly connected to the working platform 1, two sets of first electric slide rails 72 linked with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com