Phi13 spring round steel hot upset forging crack control method

A control method, hot upsetting technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as cracks on the surface of round steel, achieve the effect of improving the processing stress state and solving the problem of cracks on the surface of round steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

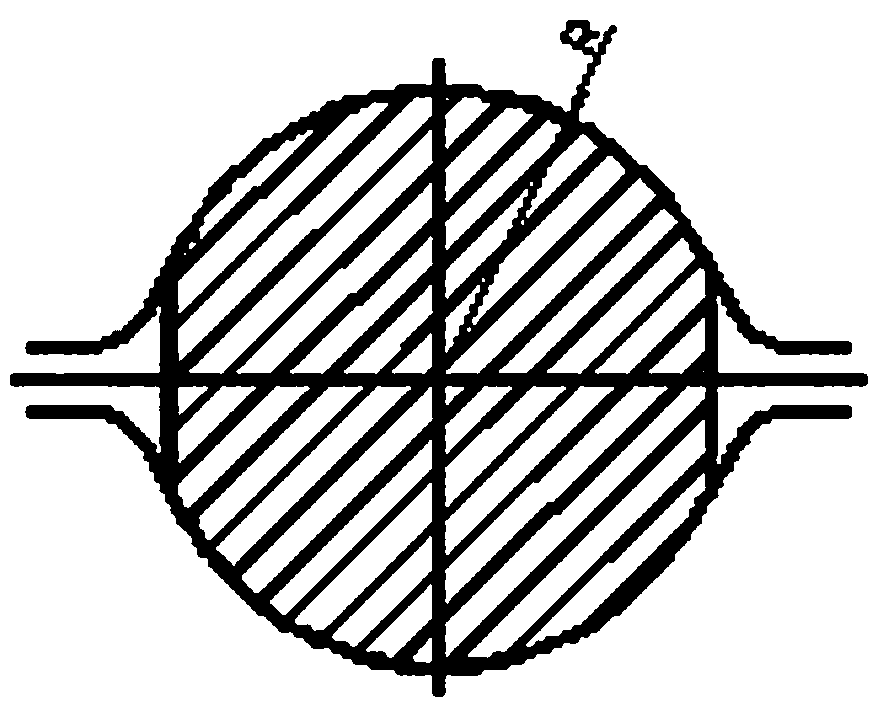

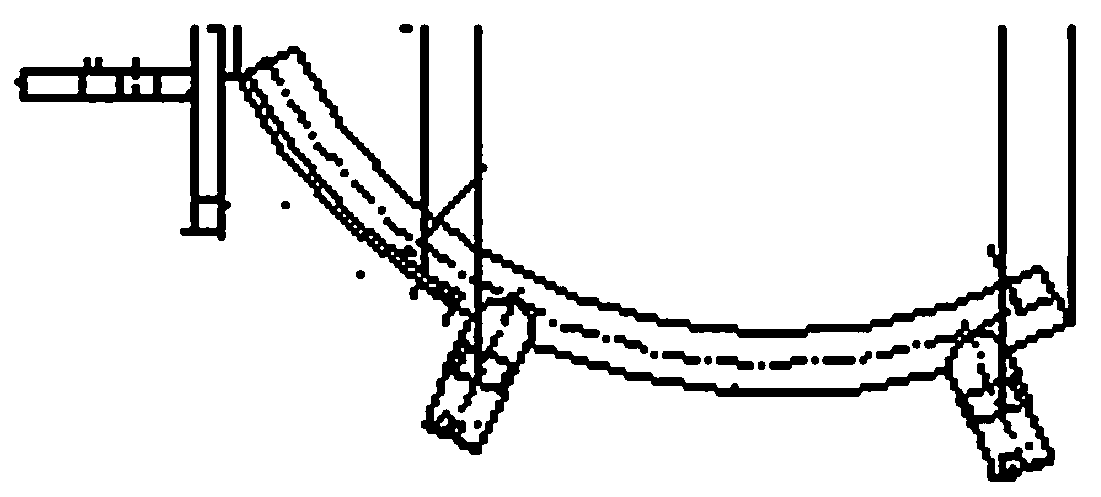

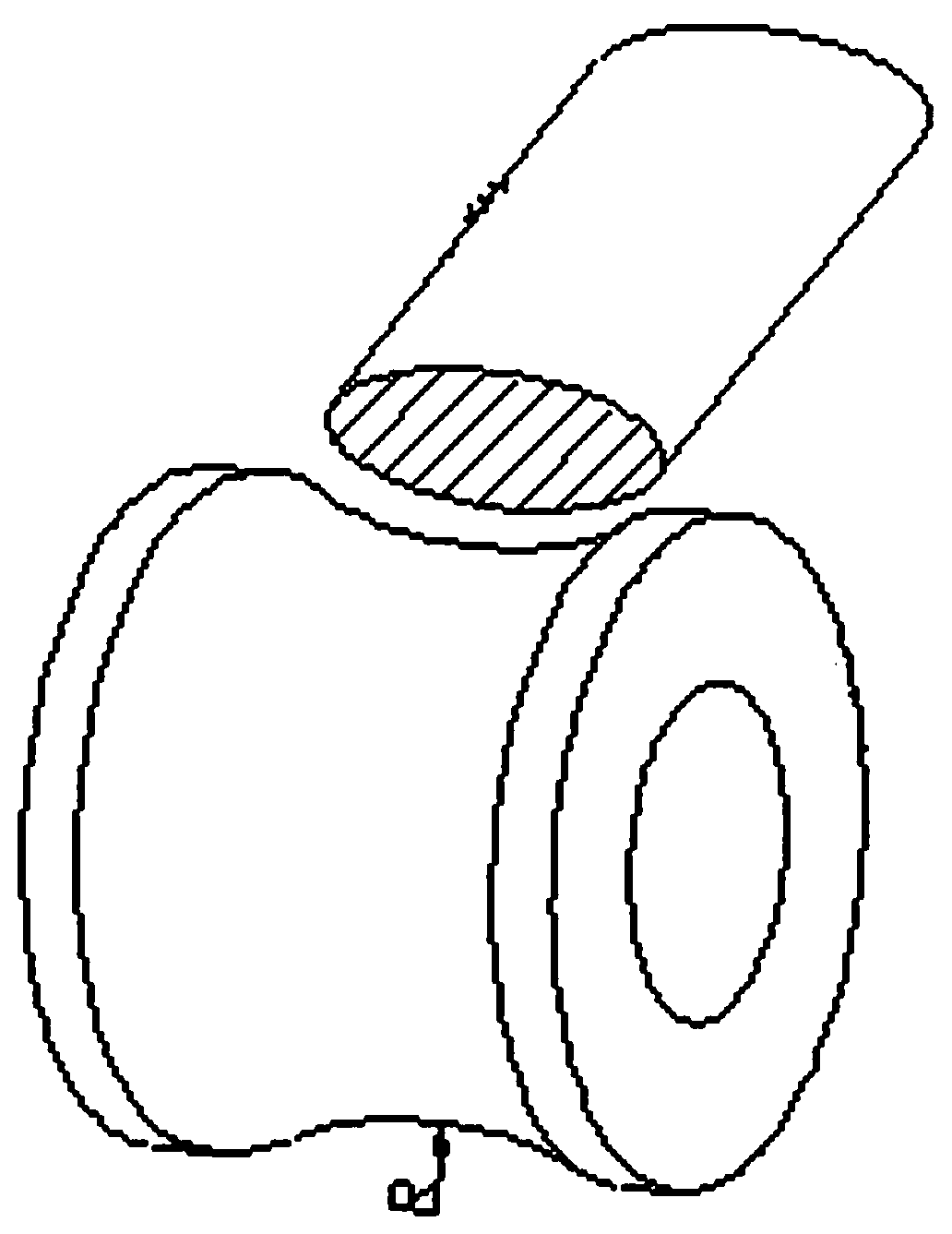

[0010] A method for controlling cracks in Φ13 spring round steel hot upset forging, comprising the following steps: 1. Re-approving and ordering process changes for the order pass types whose size and diameter are larger than the base circle of the pass type, such as figure 1 As shown, the two side walls of the round steel entering the pass are flat; 2. Change the original water nozzle cooling water pipe of the rolling mill to the hydroxyl spray cooling water pipe, increase the spray area and improve the uneven cooling of the rolling groove, resulting in large The phenomenon of area cracking, the cooling water pipe includes a circular arc pipe body, such as figure 2 As shown, two spray nozzles are arranged along the radial interval of the pipe body on the outer wall of the arc pipe body; 3. Improve the rolling guide wheel, such as image 3 As shown, the size of the arc surface of the outer circumference of the guide wheel is completely matched with the size of the arc surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com