A kind of spindle running equipment and its spindle running detection mechanism

A detection mechanism and spindle motor technology, applied in metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problems of detection and response, encoder failure, increase production and processing costs, and achieve stable detection and response. , Simple structure design, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

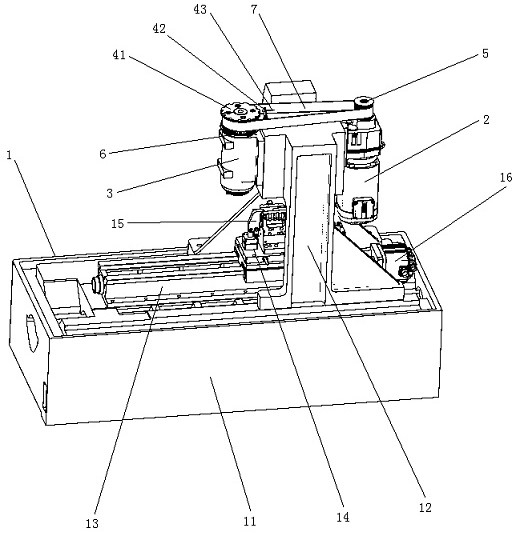

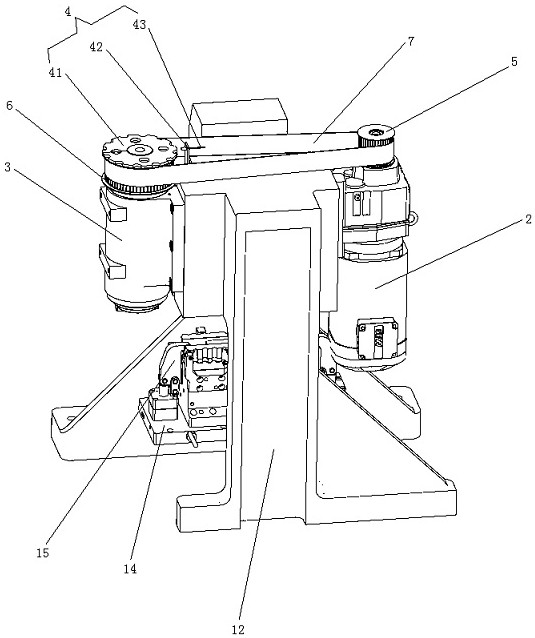

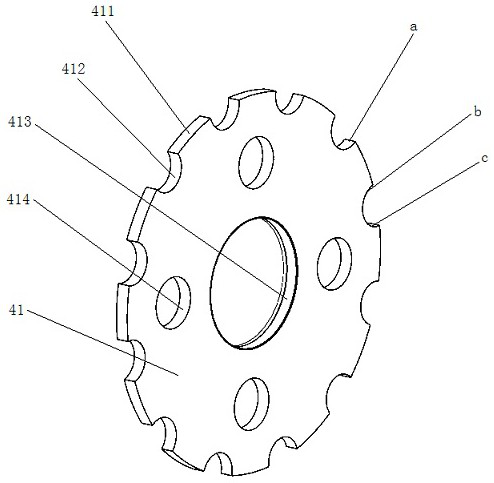

[0024] Such as Figures 1 to 3 As shown, the spindle running equipment of the present invention includes a machine tool body 1, a spindle motor 2, a power head spindle 3, a spindle running detection mechanism 4 and a machine tool electric control system.

[0025] The electric control system of the machine tool includes a PLC controller and a man-machine interface; the man-machine interface is electrically connected with the PLC controller.

[0026] The machine tool body 1 includes a workbench 11, a gantry frame 12, a guide rail 13, a slide table 14, a fixture 15 and a slide table servo motor 16; wherein, the workbench 11 is placed on the ground, and the gantry frame 12 is matched with the workbench 11 The top surface of one end of the guide rail 13 is matched with the top surface of the workbench 11; the slide table 14 is slidably installed on the guide rail 13; the slide table servo motor 16 is matched with the upper end of the workbench 11, and its power The output end is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com