Glass fiber reinforced plastic barrel manufacturing process

A manufacturing process, fiberglass technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of micro bubbles, local white spots, and low yield, and achieve easy operation, reduce production costs, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

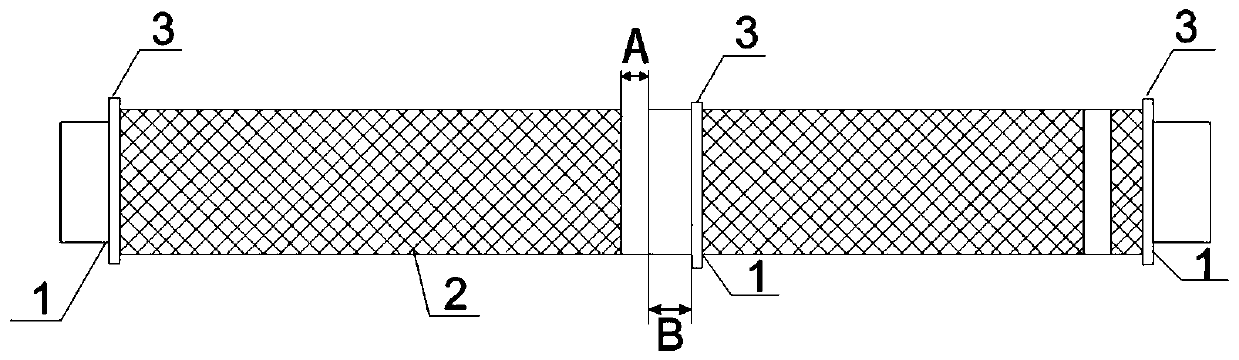

Image

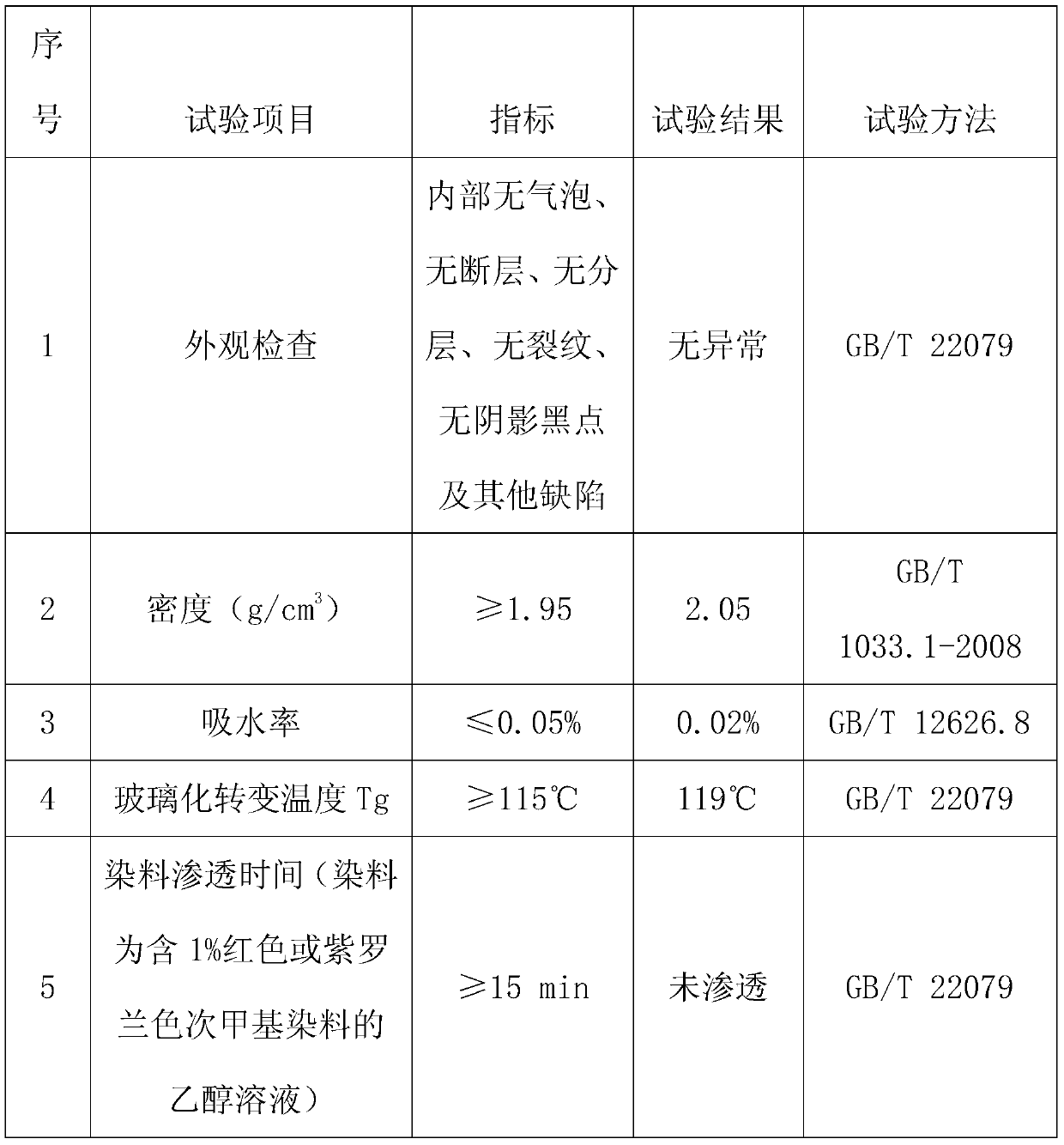

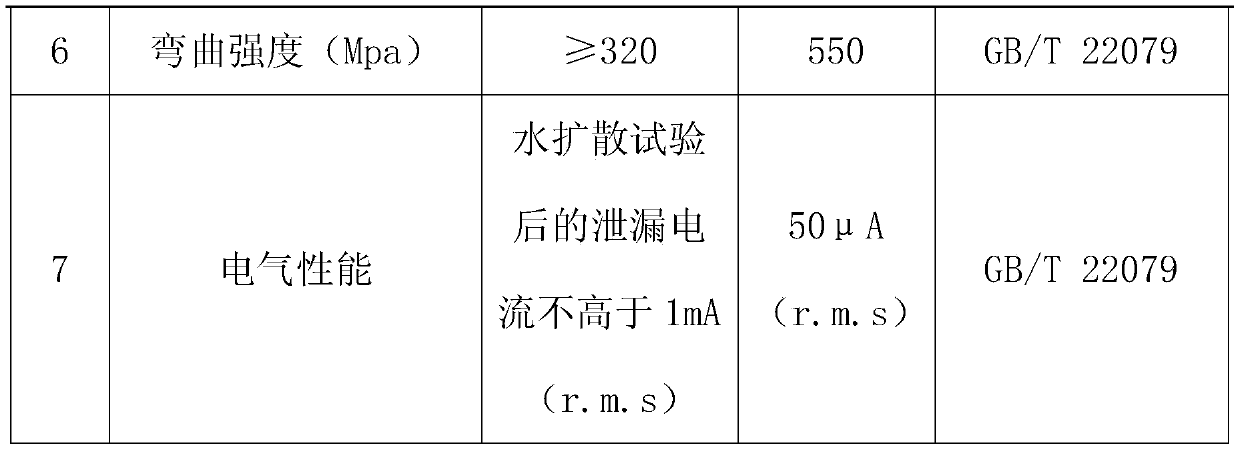

Examples

Embodiment 1

[0026] A dry-process winding vacuum-impregnated fiberglass cylinder manufacturing process, comprising the following steps:

[0027] S1: laying polyester cloth in advance, performing weaving winding and hoop winding in sequence;

[0028] S2: Assembling the vacuum dipping system;

[0029] S3: Vacuum dipping; vacuum dipping speeds up the dipping speed and improves the uniformity of dipping. Not only is the process simple and easy to operate, but it can also greatly improve production efficiency, reduce production costs, and obtain FRP cylinders with excellent comprehensive performance.

[0030] S4: curing demoulding;

[0031] S5: The blank after demolding is processed into a finished product.

[0032] In step S1, 1 mm polyester cloth is spread.

[0033] When paving, 5 layers of 0.2mm thick polyester cloth are laid by flat winding.

[0034] In step S1, glass fiber filaments are used for weaving and winding, the winding angle is 40 degrees, and when the diameter of the finished...

Embodiment 2

[0041] A dry-process winding vacuum-impregnated fiberglass cylinder manufacturing process, comprising the following steps:

[0042] S1: laying polyester cloth in advance, performing weaving winding and hoop winding in sequence;

[0043] S2: Assembling the vacuum dipping system;

[0044] S3: Vacuum dipping; vacuum dipping speeds up the dipping speed and improves the uniformity of dipping. Not only is the process simple and easy to operate, but it can also greatly improve production efficiency, reduce production costs, and obtain FRP cylinders with excellent comprehensive performance.

[0045] S4: curing demoulding;

[0046] S5: The blank after demolding is processed into a finished product.

[0047] In step S1, 1 mm polyester cloth is spread.

[0048] When paving, 5 layers of 0.2mm thick polyester cloth are laid by flat winding.

[0049] In step S1, glass fiber filaments are used for weaving and winding, the winding angle is 43 degrees, and when the diameter of the finished...

Embodiment 3

[0056] A dry-process winding vacuum-impregnated fiberglass cylinder manufacturing process, comprising the following steps:

[0057]S1: laying polyester cloth in advance, performing weaving winding and hoop winding in sequence;

[0058] S2: Assembling the vacuum dipping system;

[0059] S3: Vacuum dipping; vacuum dipping speeds up the dipping speed and improves the uniformity of dipping. Not only is the process simple and easy to operate, but it can also greatly improve production efficiency, reduce production costs, and obtain FRP cylinders with excellent comprehensive performance.

[0060] S4: curing demoulding;

[0061] S5: The blank after demolding is processed into a finished product.

[0062] In step S1, 1 mm polyester cloth is spread.

[0063] When paving, 5 layers of 0.2mm thick polyester cloth are laid by flat winding.

[0064] In step S1, glass fiber filaments are used for weaving and winding, the winding angle is 45 degrees, and when the diameter of the finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com