Fireproof liquid of composite fireproof glass and preparation method thereof and composite fireproof glass

A technology of fireproof glass and fireproof liquid, applied in the direction of adhesive type, adhesive additive, ester copolymer adhesive, etc., can solve the problem of low solid content, lower fireproof performance of composite fireproof glass, and affect the apparent quality of composite fireproof glass , optical properties, hardness and toughness, etc., to achieve good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

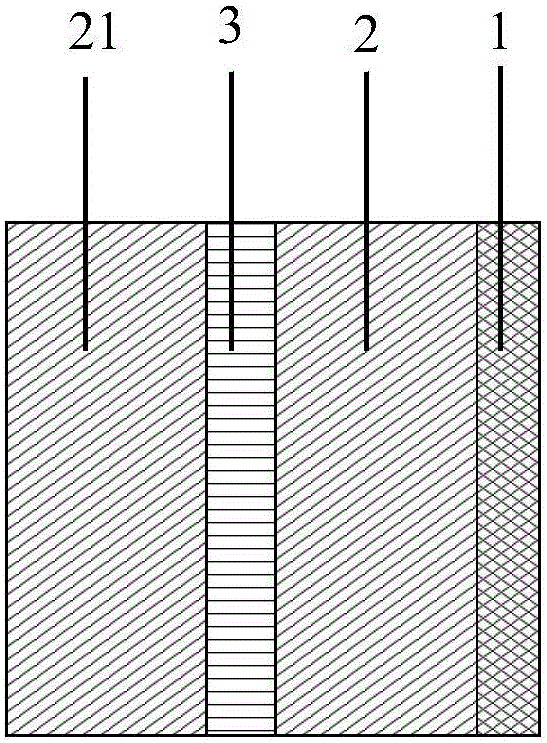

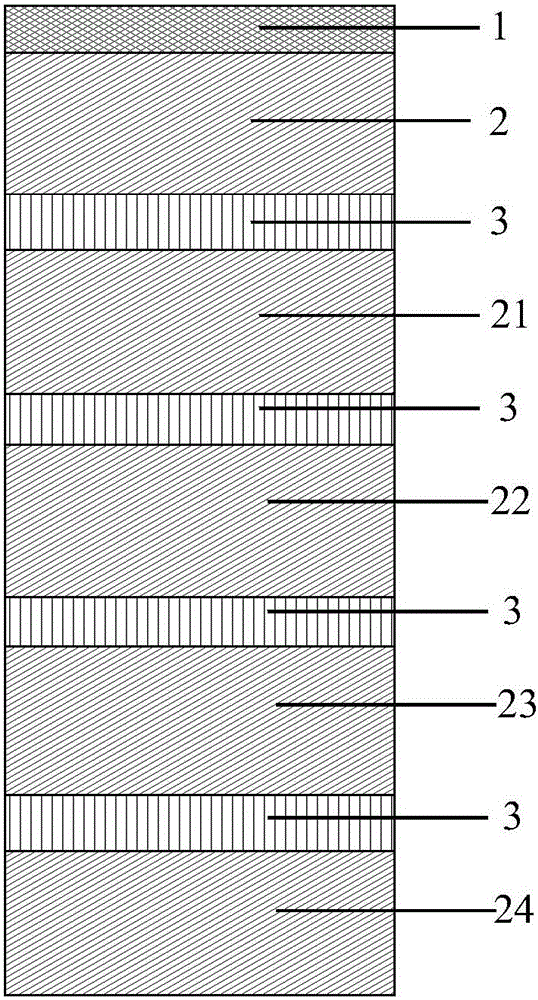

Image

Examples

Embodiment 1

[0032] First, accurately weigh 0.15kg of glycerin, 0.15kg of acrylic acid, 0.02kg of borax, 0.0005kg of sodium fluorosilicate, 0.02kg of sucrose and 0.08kg of deionized water, mix the above components, and stir thoroughly to obtain the first mixed emulsion. stand-by;

[0033] Accurately weigh 0.3kg of the above-mentioned first mixed emulsion and 0.2kg of hydrophilic nano-silica particles with a particle size of 60nm, and disperse the hydrophilic nano-silica particles in the first mixed emulsion through ultrasonic dispersion and high-speed stirring respectively , by standing for 5 hours to defoam and form a weight-stable nano-silica particle dispersion emulsion, stand-by;

[0034] Accurately weigh 0.1 kg of styrene, 0.15 kg of methyl methacrylate and 0.2 kg of butyl acrylate, mix the above components, and stir thoroughly to obtain a second mixed monomer emulsion for use;

[0035] Mix ammonium persulfate and sodium bisulfite at a molar ratio of 1:1, and use it as a redox initia...

Embodiment 2

[0041] First, accurately weigh 0.2kg of pentaerythritol, 0.2kg of methacrylic acid, 0.04kg of boric acid, 0.001kg of potassium fluorosilicate, 0.03kg of fructose and 0.12kg of deionized water, mix the above components, and stir thoroughly to obtain the first mixed lotion, ready to use;

[0042] Accurately weigh 0.32kg of the above-mentioned first mixed emulsion and 0.24kg of hydrophilic nano-silica particles with a particle size of 80nm, and disperse the hydrophilic nano-silica particles in the first mixed emulsion through ultrasonic dispersion and high-speed stirring respectively , by standing for 6 hours to defoam and form a dispersion emulsion of nano-silica particles with a stable weight, ready to use.

[0043] Accurately weigh 0.20 kg of styrene, 0.2 kg of methyl methacrylate and 0.3 kg of butyl acrylate, mix the above components, and stir thoroughly to obtain a second mixed monomer emulsion for use;

[0044] Mix ammonium persulfate and sodium bisulfite at a molar ratio ...

Embodiment 3

[0050] First, accurately weigh 0.23kg xylitol, 0.25kg polyacrylamide, 0.03kg borax, 0.03kg boric acid, 0.0015kg aluminum fluoride, 0.04kg glucose and 0.16kg deionized water, mix the above components, and stir thoroughly. Make the first mixed emulsion, stand-by;

[0051] Accurately measure 0.34kg of the above-mentioned first mixed emulsion and 0.28kg of hydrophilic nano-silica particles with a particle size of 100nm, and disperse the hydrophilic nano-silica particles in the first mixed emulsion through ultrasonic dispersion and high-speed stirring respectively , by standing for 7 hours to defoam and form a dispersion emulsion of nano-silica particles with a stable weight, ready for use.

[0052] Accurately weigh 0.20 kg of styrene, 0.25 kg of methyl methacrylate and 0.35 kg of butyl acrylate, mix the above components, and stir thoroughly to obtain a second mixed monomer emulsion for use;

[0053] Mix ammonium persulfate and sodium bisulfite at a molar ratio of 1:1 as a redox i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com