Blast furnace skip car anti-top-rushing intelligent monitoring method

An intelligent monitoring and blast furnace technology, which is applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as derailment, wind shutdown, failure to stop as required, etc., to achieve data recording, hidden danger investigation, and convenient analysis effect of cause

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

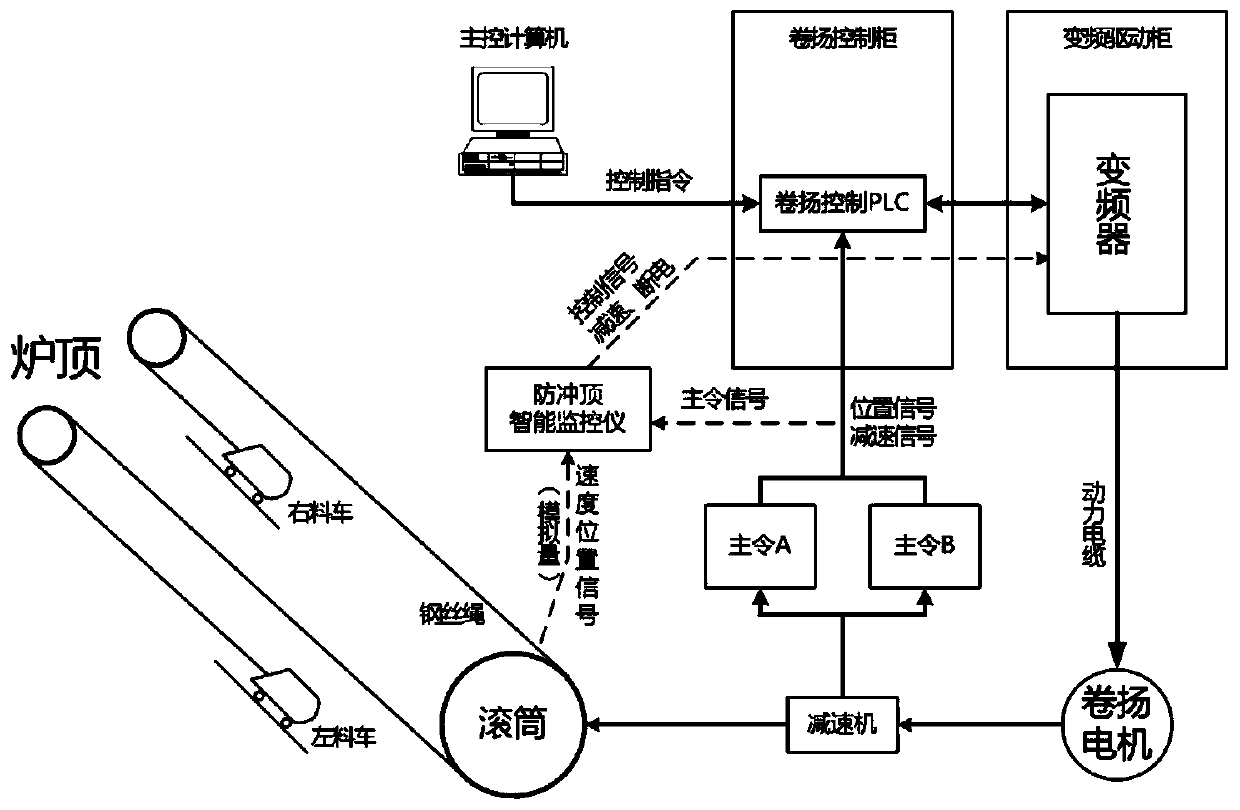

[0032] The intelligent monitoring method for the anti-rushing of the blast furnace charging car of the present invention, such as image 3 The shown is achieved through the following steps:

[0033] Step 1: access controller in the winch drag system;

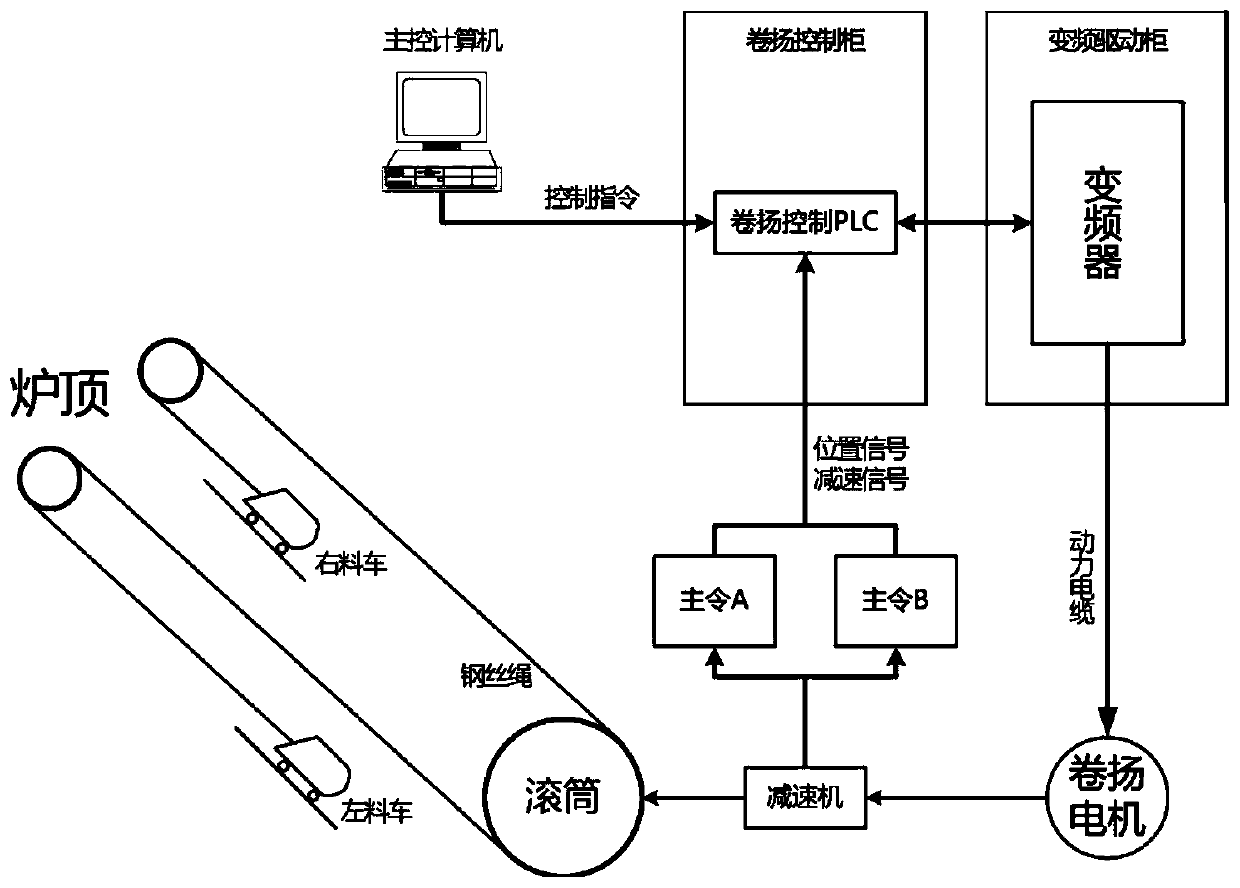

[0034] The controller uses a small PLC as the core, and the position output (switch value) of master command A and master command B is connected to the controller, and the two output signals (also switch value) of the controller are connected to the frequency converter (for speed control) ), the other is connected to the main power supply of the inverter (used to control the opening and power-off), such as Figure 4 shown.

[0035] Step 2: Determine the corresponding relationship between the running time of the blast furnace loading trolley and the rotating speed of the drum;

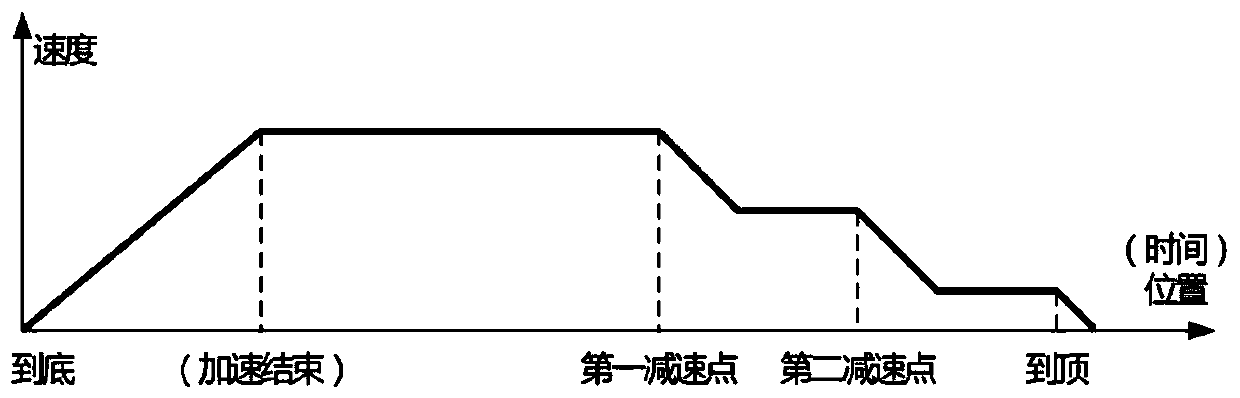

[0036] Since the running curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com