Virtual measurement method in batch manufacture procedure and system therefor

A control system and process technology, applied in the field of virtual measurement and prediction of quality management, can solve problems such as increasing production cycle time, reducing model prediction accuracy, complex control problems, etc., to reduce burden, facilitate analysis of reasons, and improve robustness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

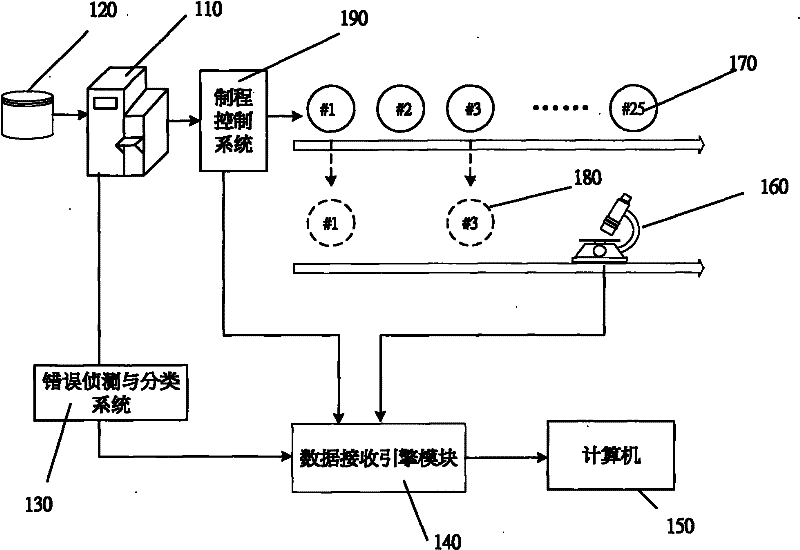

[0027] Such as figure 1 As shown: the virtual measurement system of the batch process includes: a process machine 110, a process control system (APC) 190, a fault detection and classification system (FDC) 130, a measurement machine 160, and a data receiving engine module 140 . A computer 150 for running the virtual measurement program. The measuring machine 160 is set near the output part of the process control system 190 . The output of the process machine 110 is respectively connected to the process control system 190 and the error detection and classification system 130 through signal lines. The output of the process control system 190 , the error detection and classification system 130 , and the measuring machine 160 are respectively connected to the input of the data receiving engine module 140 through signal lines, and the output of the data receiving engine module 140 is connected to the computer 150 .

[0028] A batch of wafers 120 to be processed is located at the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com