A steel wire rod heat treatment device

A technology for heat treatment devices and steel wire rods, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as broken wires, high inventory pressure, and low area shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

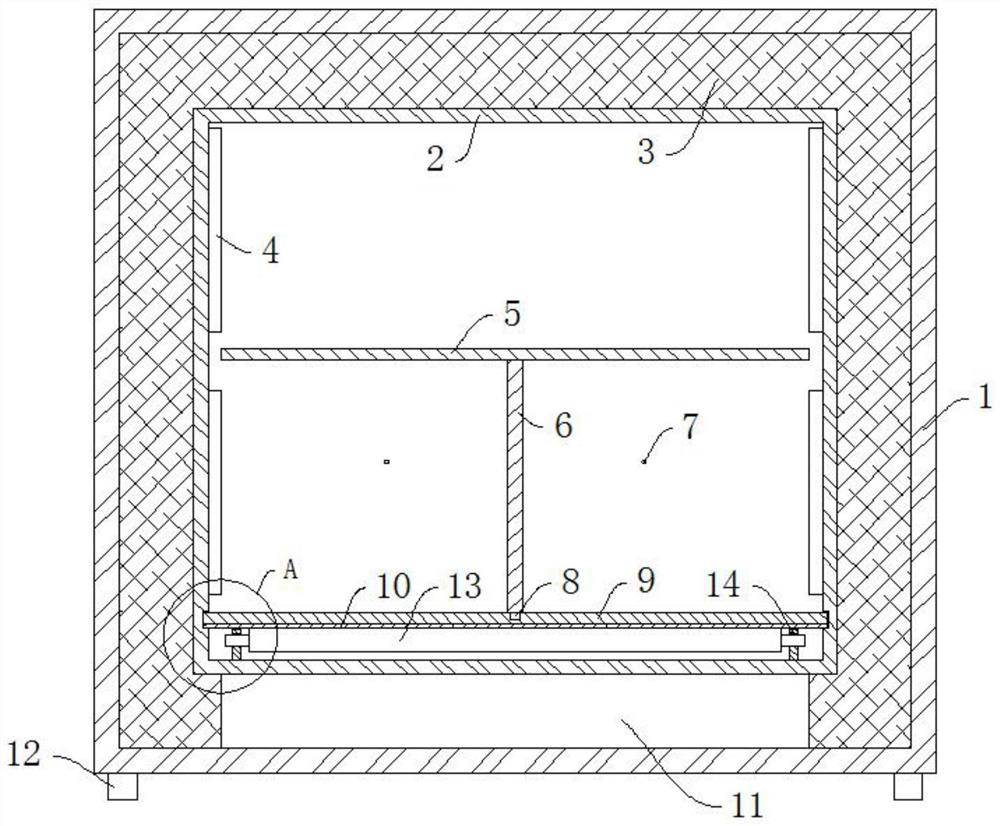

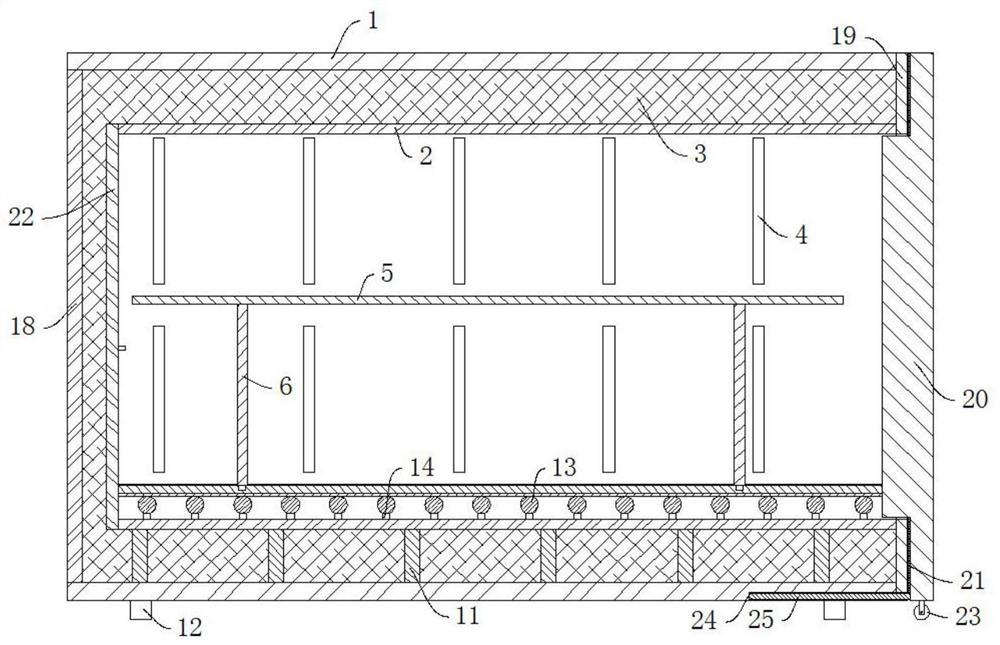

[0023] refer to Figure 1-4 , a steel wire rod heat treatment device, comprising a second sleeve 2, a plurality of heating blocks 4 are fixedly connected to the inner wall of the second sleeve 2, the heating blocks 4 are connected to an external power supply, and one end of the second sleeve 2 is fixedly connected to a side plate 22, The outer side of the second sleeve 2 is covered with the first sleeve 1, and the bottom end of the first sleeve 1 is fixedly connected with a plurality of support legs 12, and the inner side of one end of the first sleeve 1 is fixedly connected with a sealing plate 18 at the opposite side plate 22. The bottom end of the sleeve 2 is fixedly connected with a number of first support blocks 11, and the end of the first support block 11 away from the second sleeve 2 is in contact with the inner side of the first sleeve 1. The side is fixedly connected with a return-shaped block 19, the inner side of the second sleeve 2 is fixedly connected with a numb...

Embodiment 2

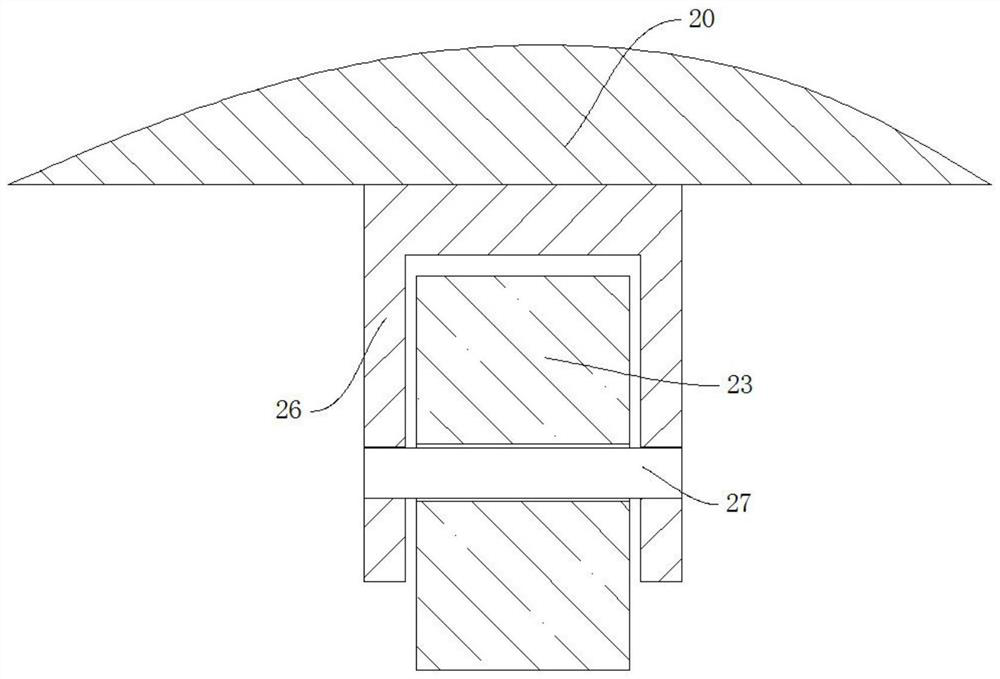

[0026] refer to image 3 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, the rolling mechanism includes a concave block 26, a roller 23, and a roller shaft 27. One end of the concave block 26 is fixedly connected to the end cover 20, and the roller 23 is located in the concave In the groove of block 26, concave block 26 has turning hole relative to roller 23 axis places, turning hole concave block 26, roller 23, and roller 27 is positioned at turning hole, facilitates the movement of end cap 20 by roller 23.

Embodiment 3

[0028] refer to figure 2 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, a guide rod 25 is fixedly connected to the bottom of one side of the end cover 20 relative to the return block 19, and the return block 19 is provided with a guide groove 24 relative to the guide rod 25, The guide groove 24 runs through the return-shaped block 19 and extends into the first sleeve 1, and the end of the guide rod 25 away from the end cover 20 is located in the guide groove 24, and the end cover 20 is relatively returned to the return-shaped block 19 through the guide groove 24 and the guide rod 25. move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com