A method of blasting ore extraction to reduce the collapse of the filling body in the two-step mining room

A mining method and backfill technology, which are applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of large collapse of the backfill and depletion of raw ore grade, and achieve the purpose of reducing the frequency of safety accidents, easy operation, and reducing The effect of human and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

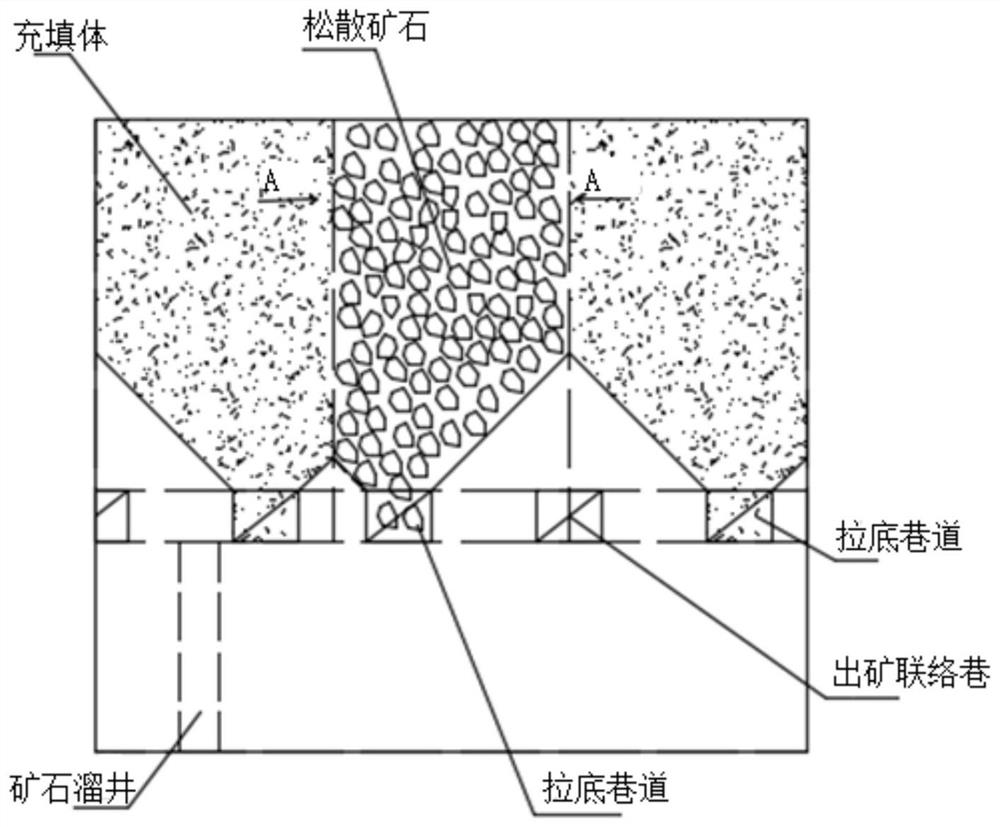

[0042]The mining method is mainly for the ore body thickness of more than 60m in the vertical deep hole stage, and the mining method of ore mining in the segmented rock drilling stage is mainly for the ore body thickness of 30-60m and the segmented empty stop and then filling mining method. For the ore body thickness of 20-30m, there are three main methods, and the three methods are divided into two steps of mining: one-step mining room and two-step mining room; construction of one-step bottom roadway and one-step mining room recovery. The filling is completed, and now the large-scale mining of the second-step mining room is started, and the second-step bottoming roadway is constructed for the second-step mining work. However, because the strength of the tailings cemented filling body cannot be compared with the hardness of the original ore, it is now facing large-scale mining. Under the action of ground pressure and blasting during room blasting, when a large-volume goaf is fo...

Embodiment 2

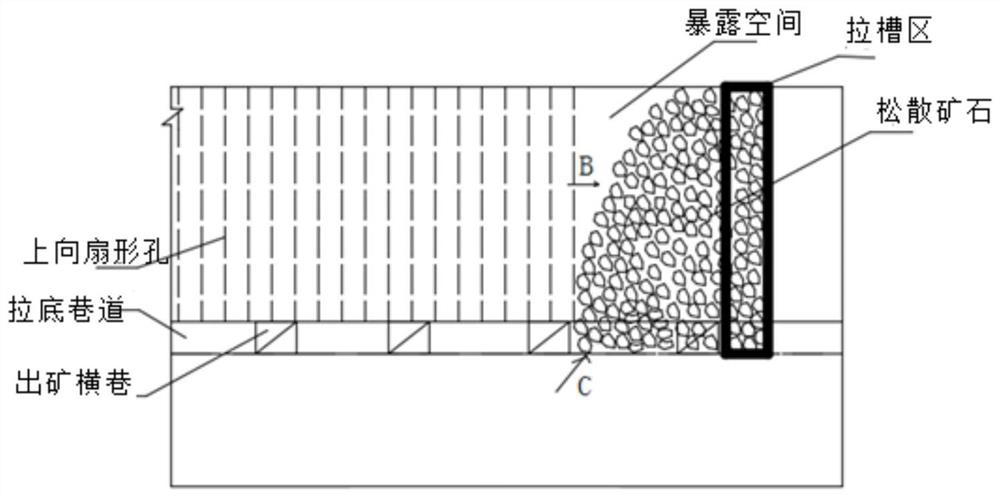

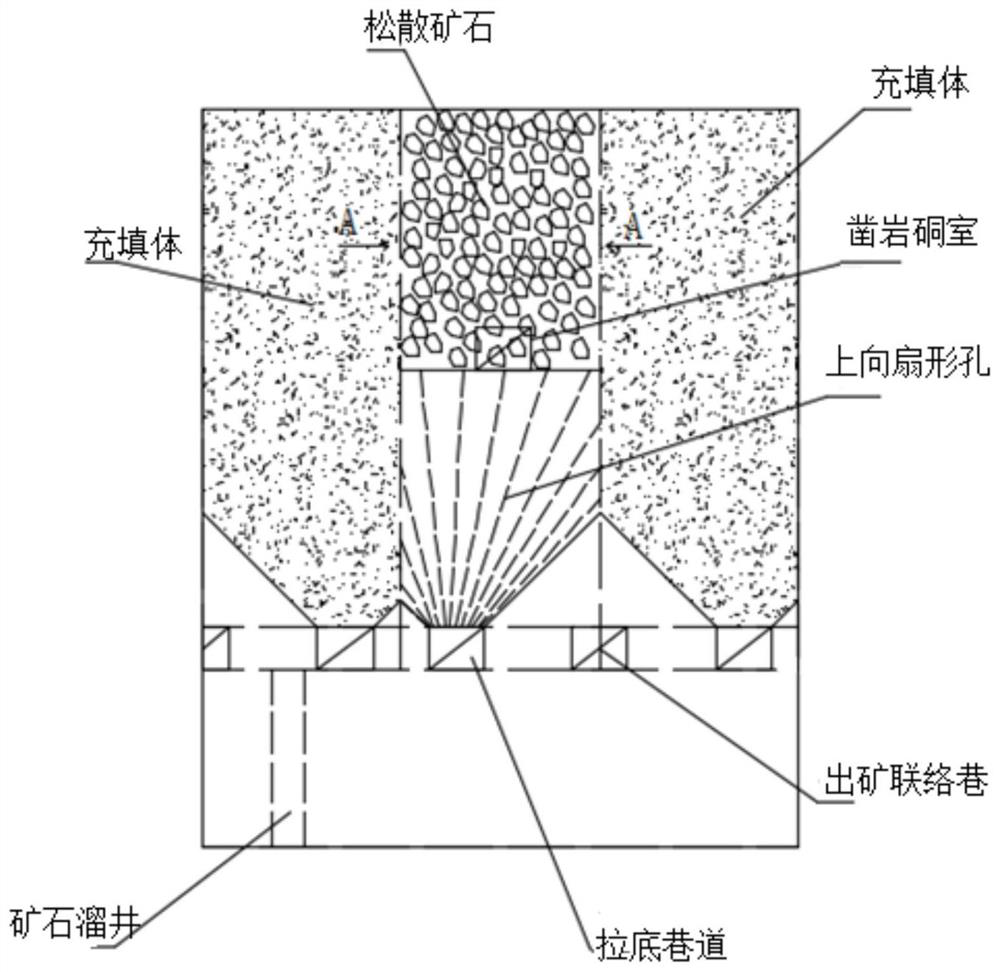

[0051] like figure 1 and figure 2 As shown, it is basically the same as in Example 1, and what is different from Example 1 is that the present embodiment is aimed at the subsection empty field and then filling mining method. When the method is carried out in the two-step mining room back mining, the preliminary work is as follows: the mining method mine room The height is 20-30m, and one segmental mining, the slotting holes are vertical deep holes, and the row holes are upward fan-shaped deep holes. The punching positioning device comprises a positioning rod, the top of the positioning rod is horizontally fixed with a telescopic rod, the top of the telescopic rod is upwardly fixed with an angle measuring instrument, the angle measuring instrument is provided with a laser emitter, and the telescopic rod includes an outer rod and an inner rod, the outer rod The rod and the inner rod are fixed by a fixed ring, and a rubber ring is arranged in the fixed ring. The rubber ring has...

Embodiment 3

[0058] like Figure 5 , Image 6 and Figure 9 As shown, it is basically the same as in Example 2. The difference from Example 2 is that this example is aimed at the large-diameter vertical deep hole stage empty field and then filling mining method. When this method is used for two-step mining room recovery, the preliminary work is as follows: The two-step mining of this method is divided into two stages of mining. The upper segment row of holes is a large-diameter hole with a depth of 50-55m downward vertical deep holes, and the lower segment row of holes is an upward fan-shaped deep hole of 20-30m. 85m, the slotting hole is divided into two vertical deep holes for slotting. Therefore, the upper row of holes in the mine room is a large-diameter vertical deep hole, and the lower row of holes is an upward fan-shaped hole. It belongs to a high-level mine room, and the blasting control requirements are relatively High, before the stope is put into production, a detailed stope b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com