Brake pad for high-speed train

A technology for high-speed trains and brakes, which is applied in the direction of friction linings, gear transmission mechanisms, and other chemical processes, and can solve the problems of weak shear resistance and impact resistance of bonding surfaces, weak shear resistance and impact resistance , There are problems such as safety risks, and achieve the effects of good wear resistance, improved service life, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

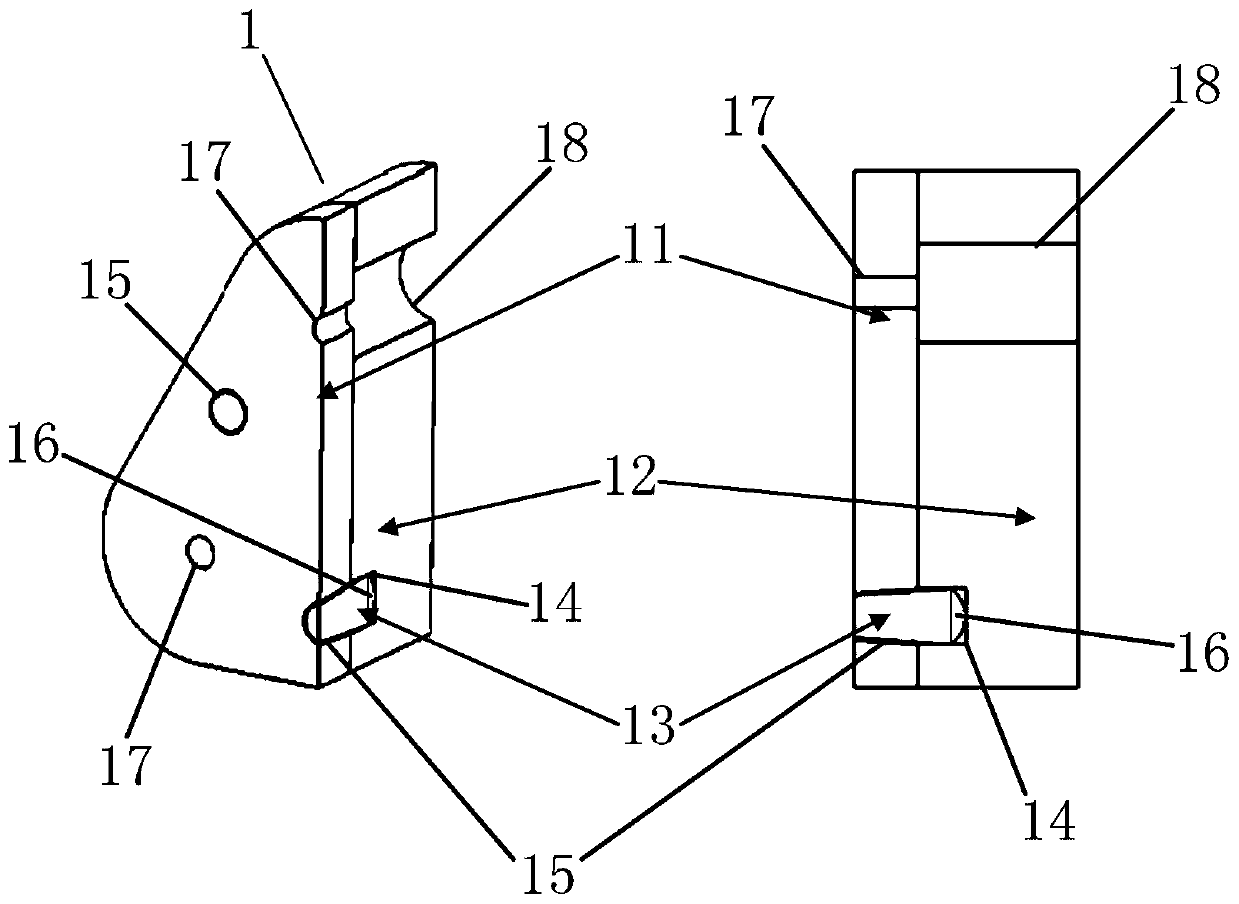

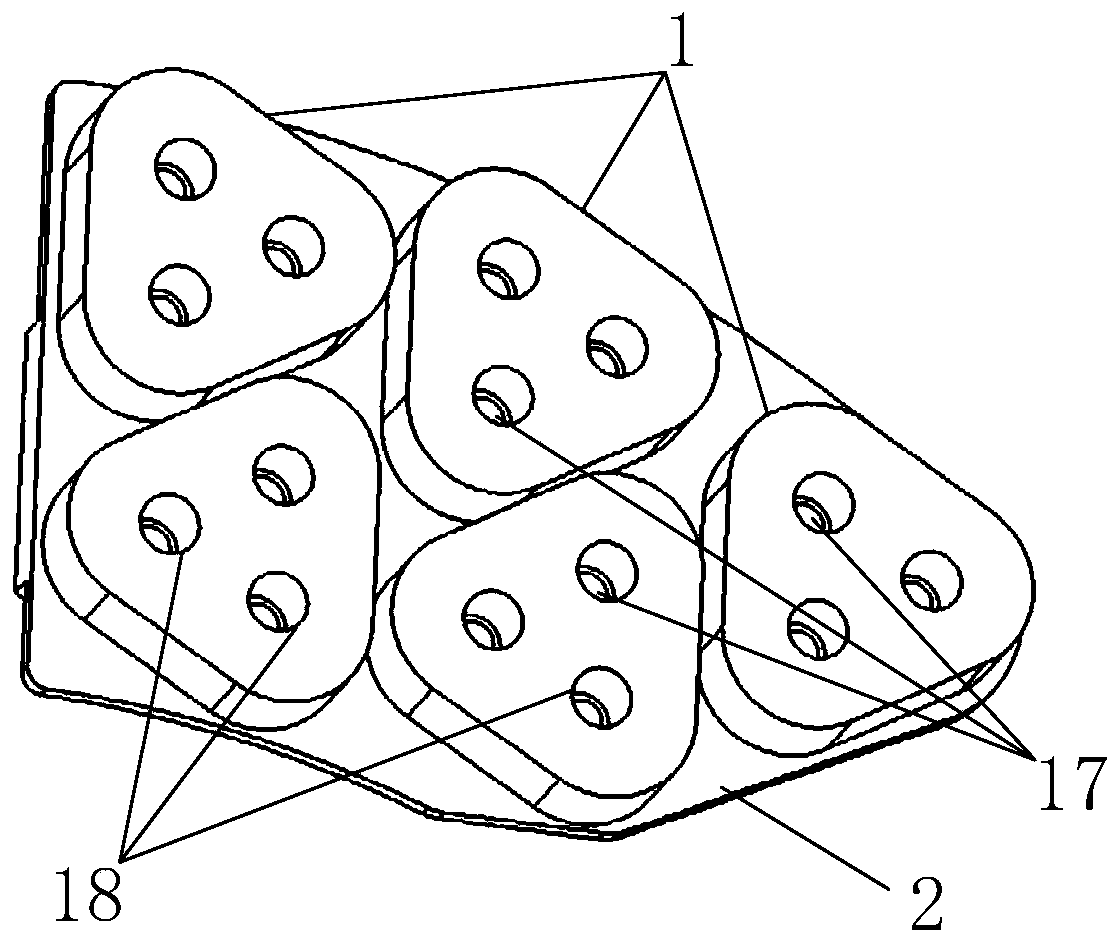

[0044] like figure 1 and figure 2 As shown, the brake pad includes a brake pad steel back 2 and a friction block 1, the friction block 1 includes a friction block steel back 11, a compact 12 and a reinforcing pin 13, the compact 12 is provided with a blind hole 14, and the friction block steel The back 11 is provided with a through hole 15 connected with the blind hole 14, and the two ends of the reinforcement pin 13 are respectively clamped in the blind hole 14 and the through hole 15, which are used to strengthen the shear resistance and impact resistance of the friction block 1. The green compact 12 is fixedly connected to the steel back 11 of the friction block, and the steel back 2 of the brake pad is fixedly connected to the steel back 11 of the friction block.

[0045] Further, as figure 1 As shown, the bottom of the blind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com