Metal standard substance for testing low or ultralow permeability

A technology of ultra-low permeability and standard products, which is applied in the field of standard products for testing instrument calibration, and can solve problems such as low permeability, limited use of standard products, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In some embodiments, the preparation method of the metal standard product further includes: grinding the side of the prepared standard product. Grinding makes the shape of the prepared standard more regular, thereby further improving the accuracy of measurement. It should be understood that the top and bottom surfaces of the prepared standards were not ground. If the top surface and the bottom surface of the prepared standard product are polished, it is easy to cause the pores on the top surface and the bottom surface to be blocked, which will affect the value of the permeability. In a specific embodiment, the gas permeability measurement is under the covering pressure, measuring the gas permeability in the vertical direction of the cylinder, and the surrounding air pressure is closed, so the side processing does not affect the value.

[0052] The metal standard product of the present invention is measured with a CMS-300 pressure-covered porosity tester from American C...

Embodiment 1

[0056] Using nickel powder with an average particle size of 2 μm as the raw material, a cylindrical standard product with a diameter of 2.5 cm, a height of 4.7 cm, and a compaction rate of 91.5% was produced. Porosity and permeability repeatability testing.

[0057] The production process of the metal standard is as follows:

[0058] 1) calculate the weight M of required nickel powder according to above-mentioned formula (1) 镍 178g;

[0059] 2) Add 178g of nickel powder into the mould, put it on the press, release the pressure when the nickel powder in the mold is pressed to a standard product height of 4.7cm, and take it out to obtain a molded semi-finished product;

[0060] 3) Put the molded semi-finished product into a vacuum sintering furnace, sinter at 900°C for 1 hour, take it out after cooling, and obtain a nickel standard product.

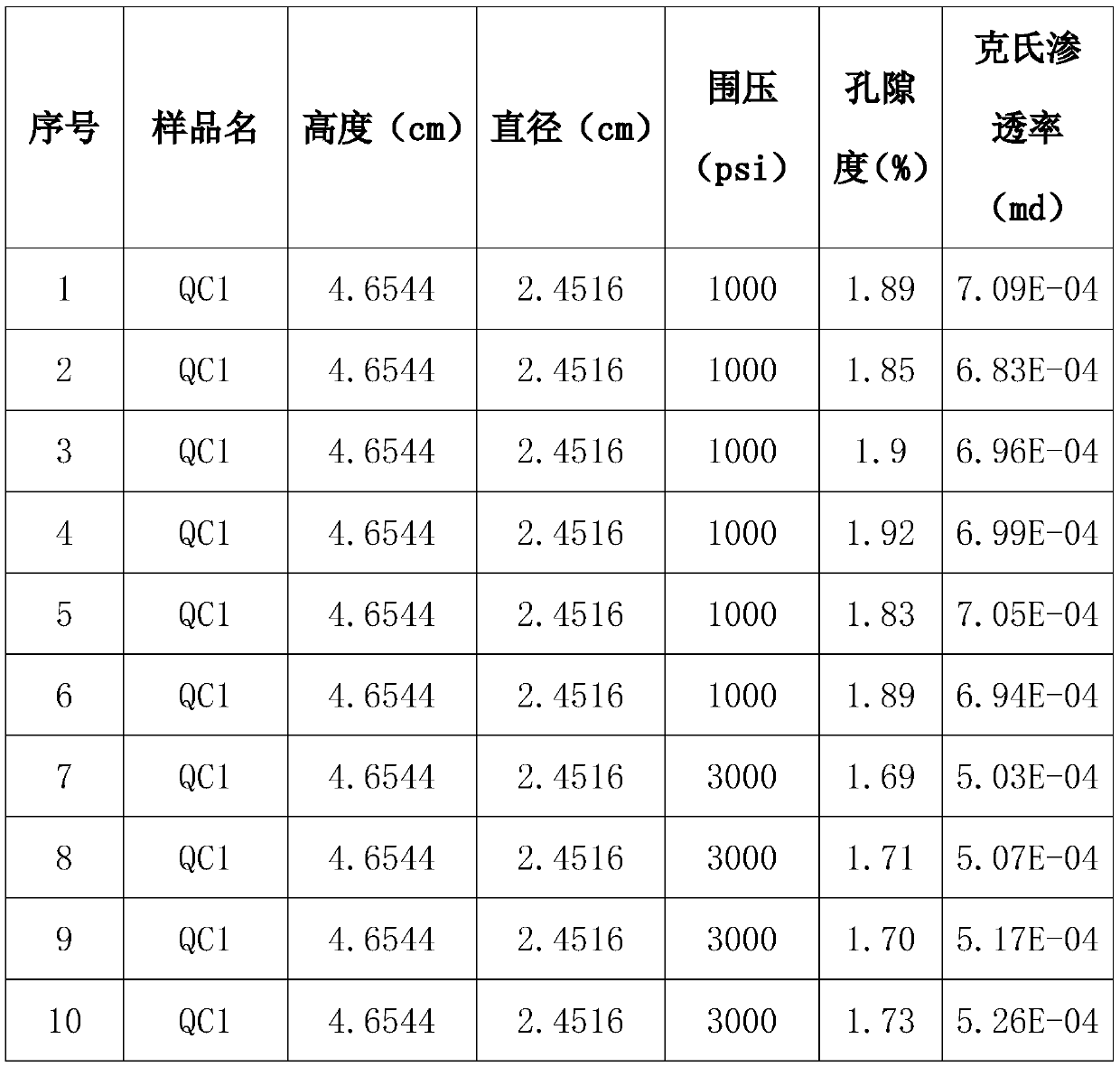

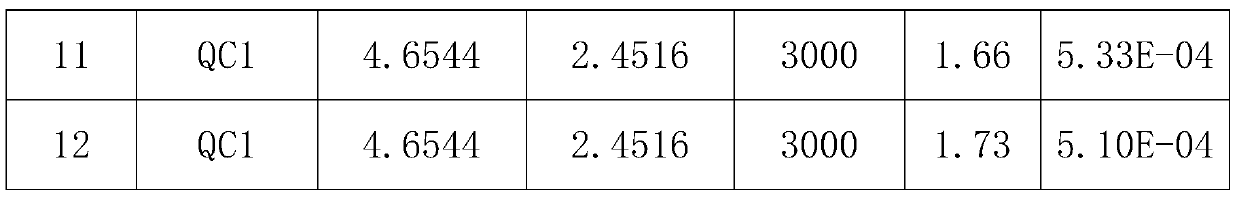

[0061] Testing of nickel standard product: The porosity and K-permeability of the nickel standard product prepared in this embodiment w...

Embodiment 2

[0070] Using nickel powder with an average particle size of 2 μm as the raw material, a cylindrical standard product with a diameter of 2.5 cm, a height of 4.7 cm, and a compaction rate of 92% was produced. Porosity and permeability testing.

[0071] The production process of the metal standard is as follows:

[0072] 1) calculate the weight M of required nickel powder according to above-mentioned formula (1) 镍 180g;

[0073] 2) Add 180g of nickel powder into the mould, put it on the press, release the pressure when the nickel powder in the mold is pressed to a standard product height of 4.7cm, and take it out to obtain a molded semi-finished product;

[0074] 3) Put the molded semi-finished product into a vacuum sintering furnace, sinter at 900°C for 1 hour, take it out after cooling, and obtain a nickel standard product.

[0075] Testing of nickel standard product: The porosity and K-permeability of the nickel standard product prepared in this embodiment were repeatedly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com