Automatic detection method for point cloud rivet levelness

An automatic detection and rivet technology, applied in the field of aircraft rivet detection, can solve the problems of low reliability, low efficiency, high missed detection rate, and achieve the effect of improving efficiency and accuracy, high measurement accuracy and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

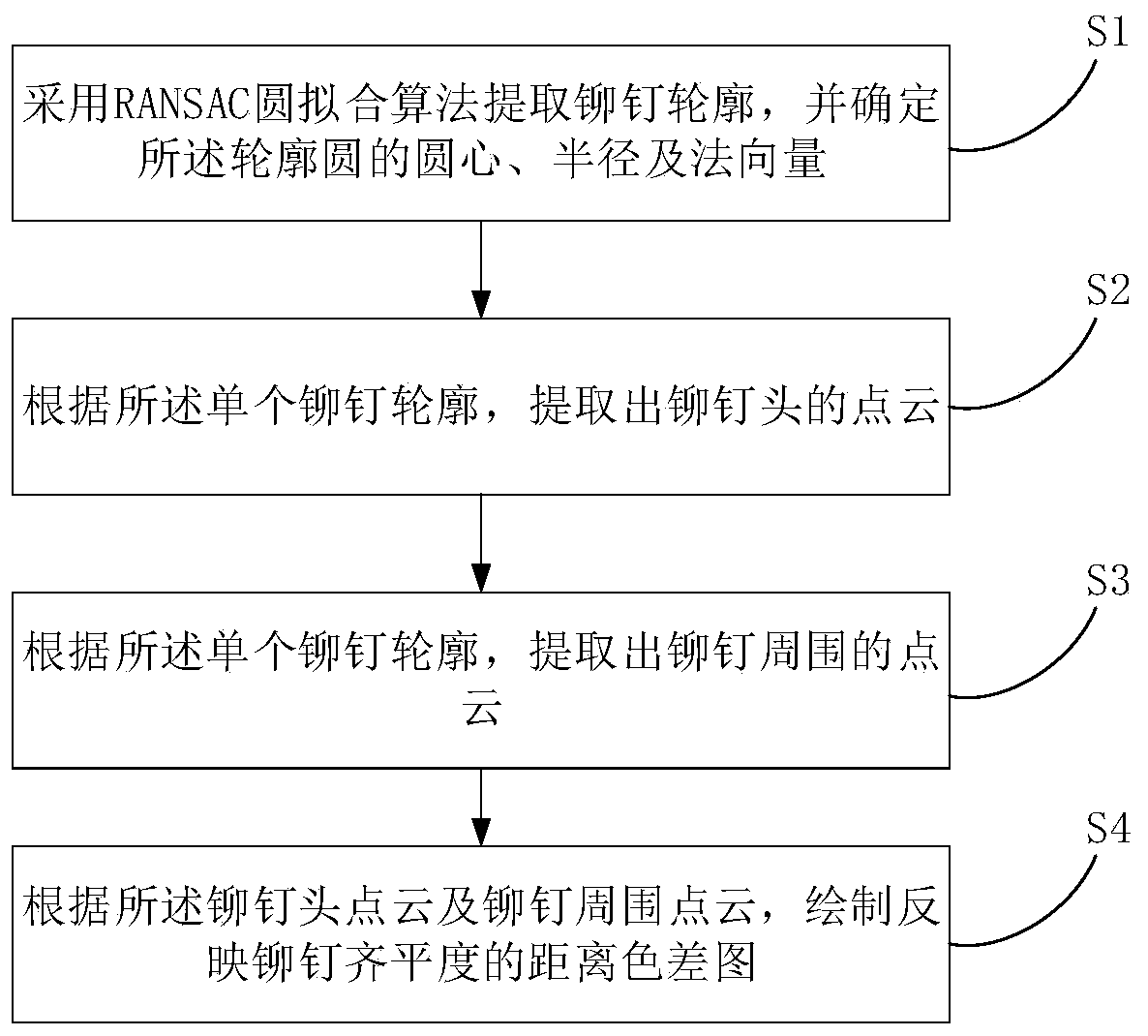

[0046] In order to solve the problem that the rivet flushness cannot be quantitatively measured in the prior art, the present invention provides an automatic detection method for point cloud rivet flushness, figure 1 An optional flowchart showing the automatic detection method, as figure 1 As shown, the detection method includes the following steps:

[0047] S1: Using the RANSAC circle fitting algorithm to extract the rivet contour, and determine the center, radius and normal vector of the contour circle.

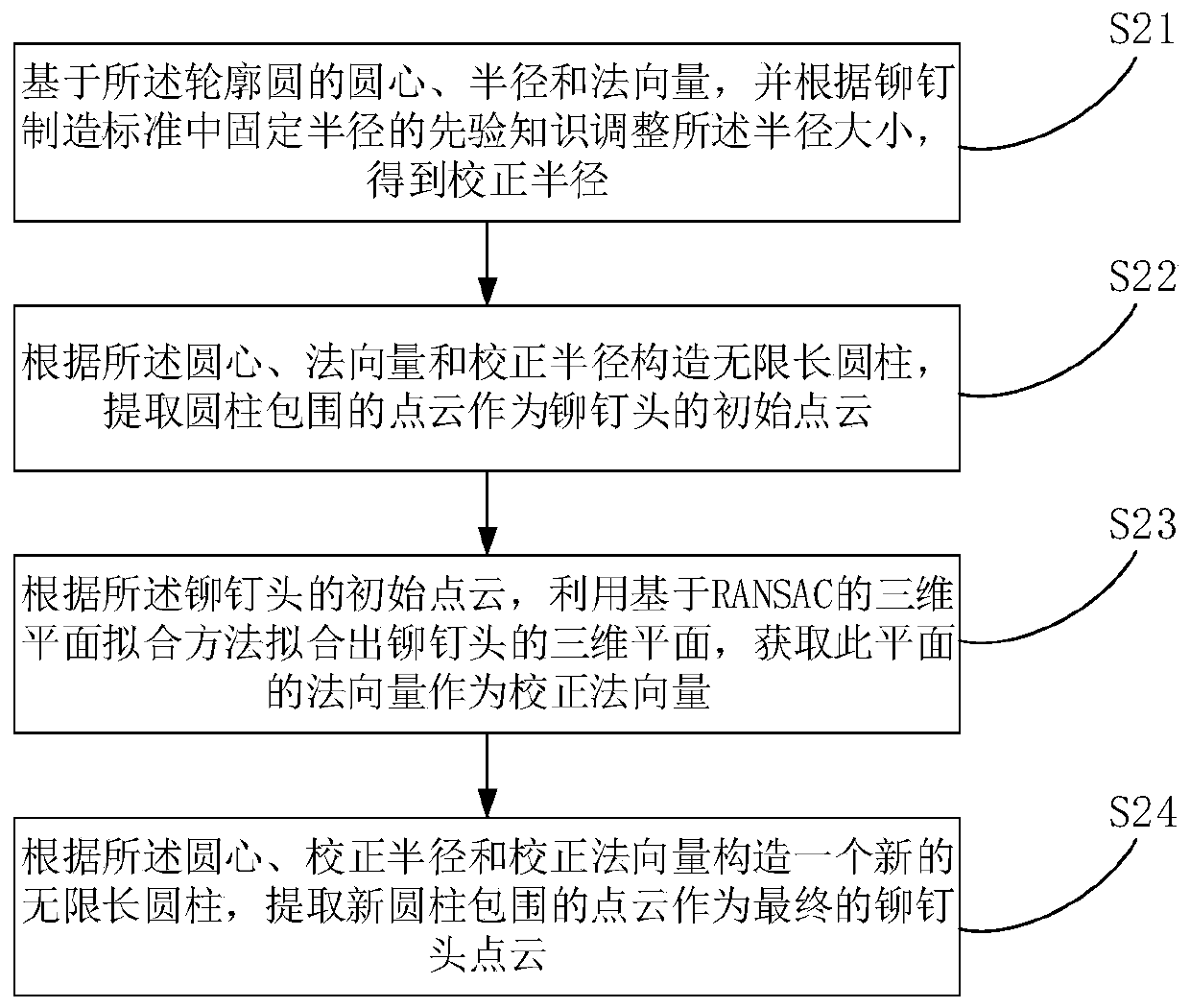

[0048] S2: Extract the point cloud of the rivet head according to the profile of the single rivet.

[0049] S3: Extract a point cloud around the rivet according to the outline of the single rivet.

[0050] S4: According to the point cloud of the rivet head and the point cloud around the rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com